Wire type surface tinning device and improved tinning technological method thereof

A technology of tin plating device and surface treatment device, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of poor tin unevenness, product appearance influence, poor tin permeability, etc., and achieve good tin The effect of the degree of impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

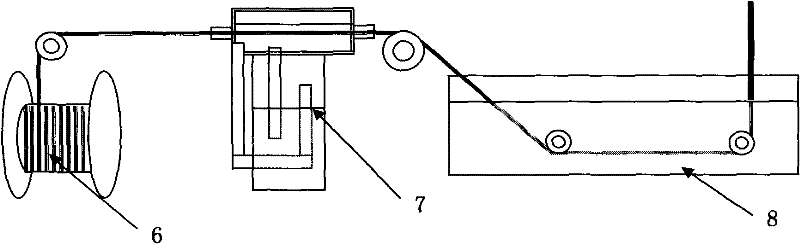

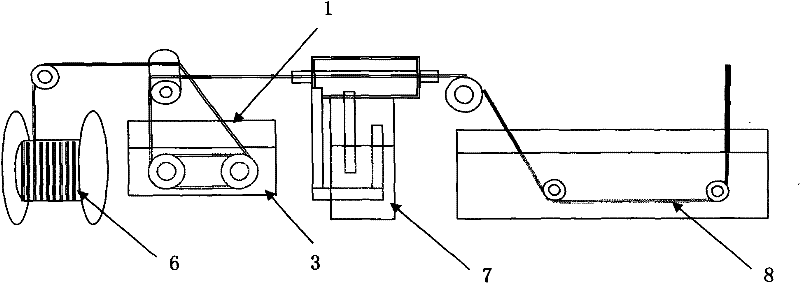

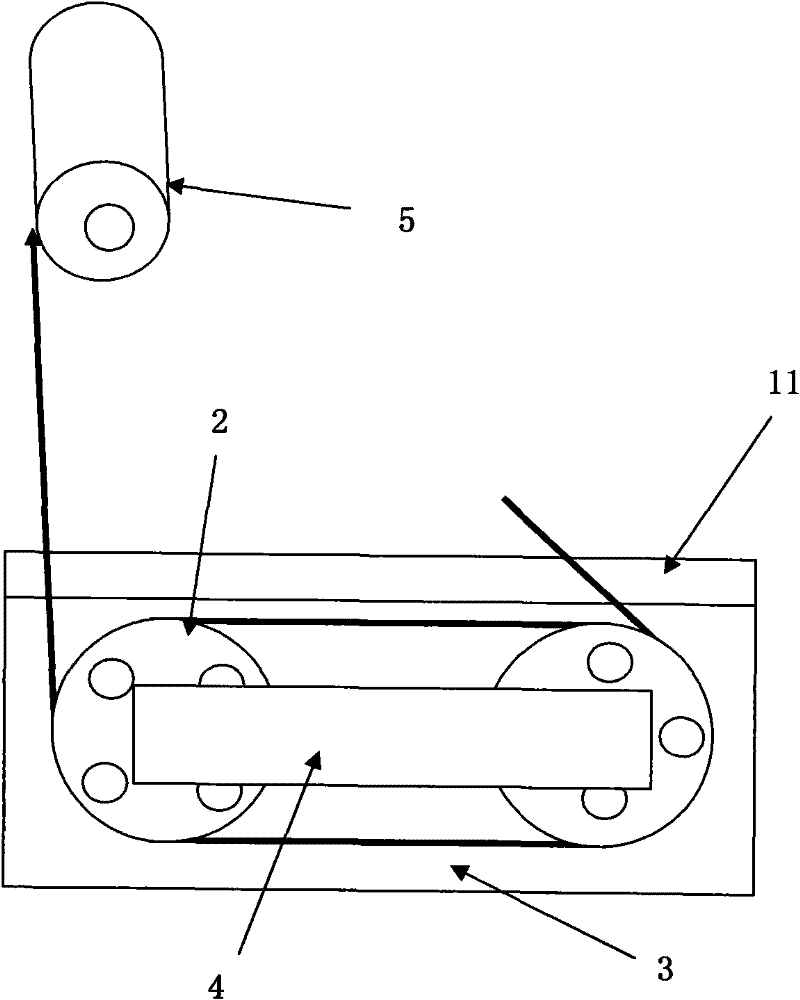

[0016] Embodiment: a kind of wire surface tin plating device, it mainly comprises to-be-plated product 6, cleaning treatment circulation tank 7 and tin-plating tank 8, is also provided with a surface treatment device 1, and described surface treatment device 1 is arranged on the to-be-plated product 6 and the cleaning treatment circulation tank 7, the surface treatment device includes a treatment tank 11, in which at least one set of multi-groove wheel sets 2 is arranged, and each set of multi-groove wheel sets 2 is provided with at least one groove Wheel, the multi-groove wheel set 2 can rotate freely in the treatment tank 11, the treatment liquid 3 is housed in the treatment tank 11, and the multi-groove wheel set can be completely immersed in the treatment liquid;

[0017] The treatment tank 11 of the surface treatment device 1 is provided with two groups of multi-groove wheel sets 2, and a cross bar 4 is provided. The radial planes of the corresponding groove wheels in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com