Foundation pit reinforcing technology from shallow position to deep position for group pit construction

It is a technology of shallow foundation pit first and then deep foundation pit, which is applied in infrastructure engineering, excavation, construction, etc., and can solve the problems that deep foundation pits cannot be constructed first

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

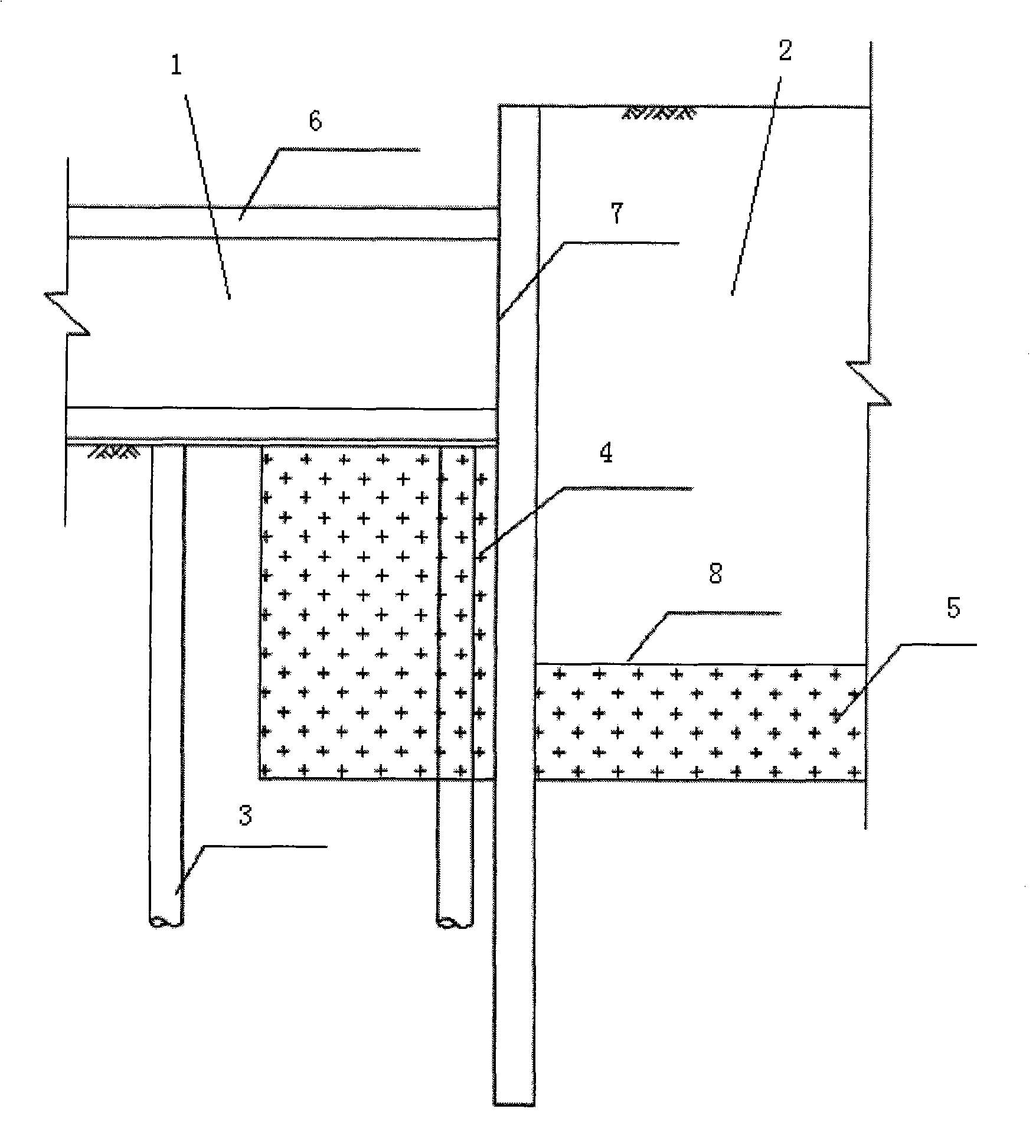

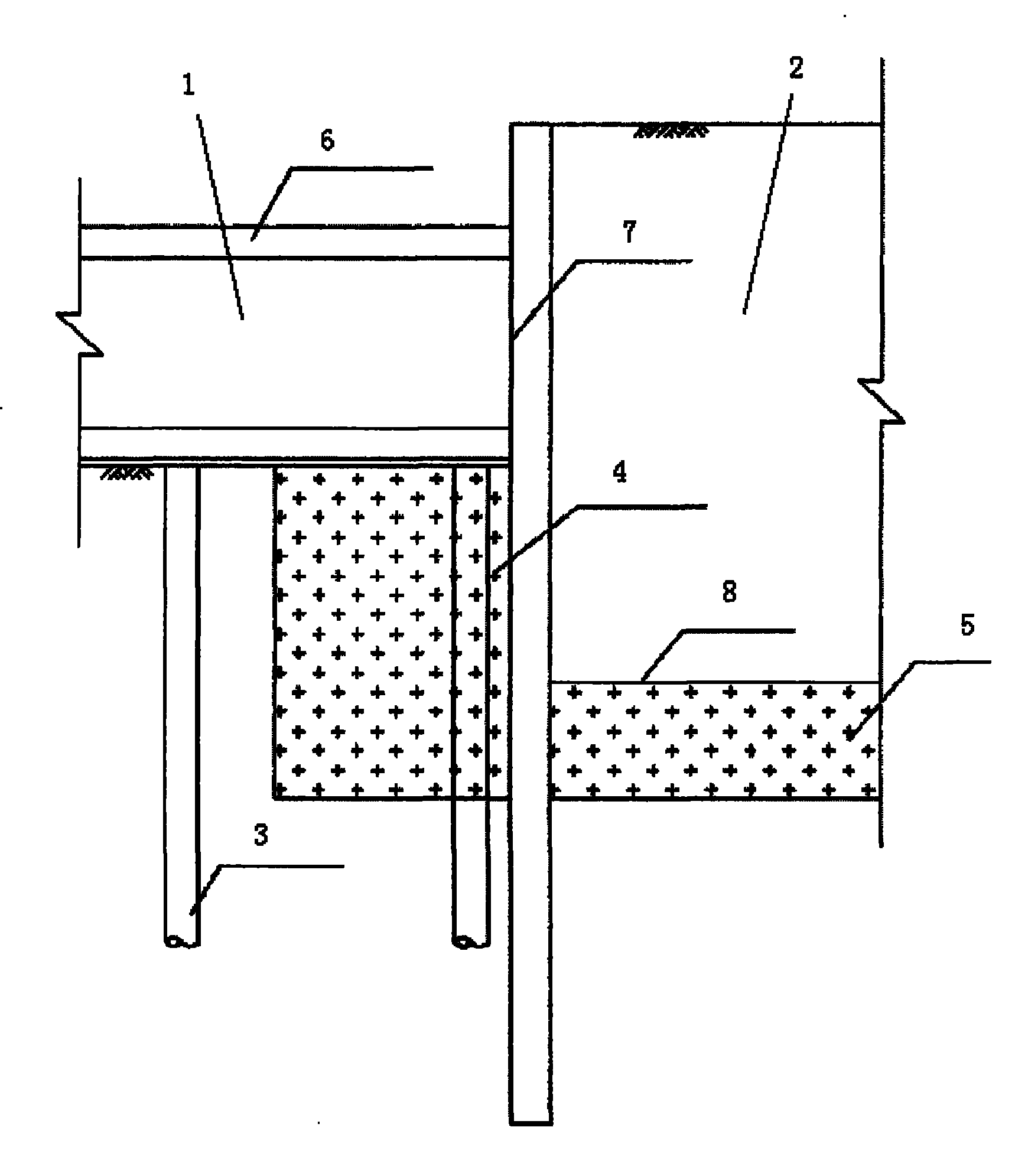

[0007] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0008] A foundation pit reinforcement technology in which group pits are first shallow and then deep, characterized in that the shallow pit 1 is constructed first, the anti-floating capacity of the shallow pit 1 is increased, and the shallow pit area adjacent to the shallow pit 1 and the deep pit 2 is reinforced with soil 4. Dig deep pit 2 again, and use multiple concrete supports for construction when excavating the deep pit. Increasing the anti-floating capacity of the shallow pit includes setting reinforcement piles 3 in the shallow pit. The soil reinforcement 4 of the shallow pit area adjacent to the deep pit includes the reinforcement of jet grouting piles, and the reinforcement depth is from the bottom of the shallow pit to the depth of reinforcement 5 at the bottom of the deep pit. According to an embodiment of the present invention, the depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com