Walking support

A self-moving, support frame technology, applied in mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of less effective footage time and waste of working time, saving working time, reducing labor intensity and working efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

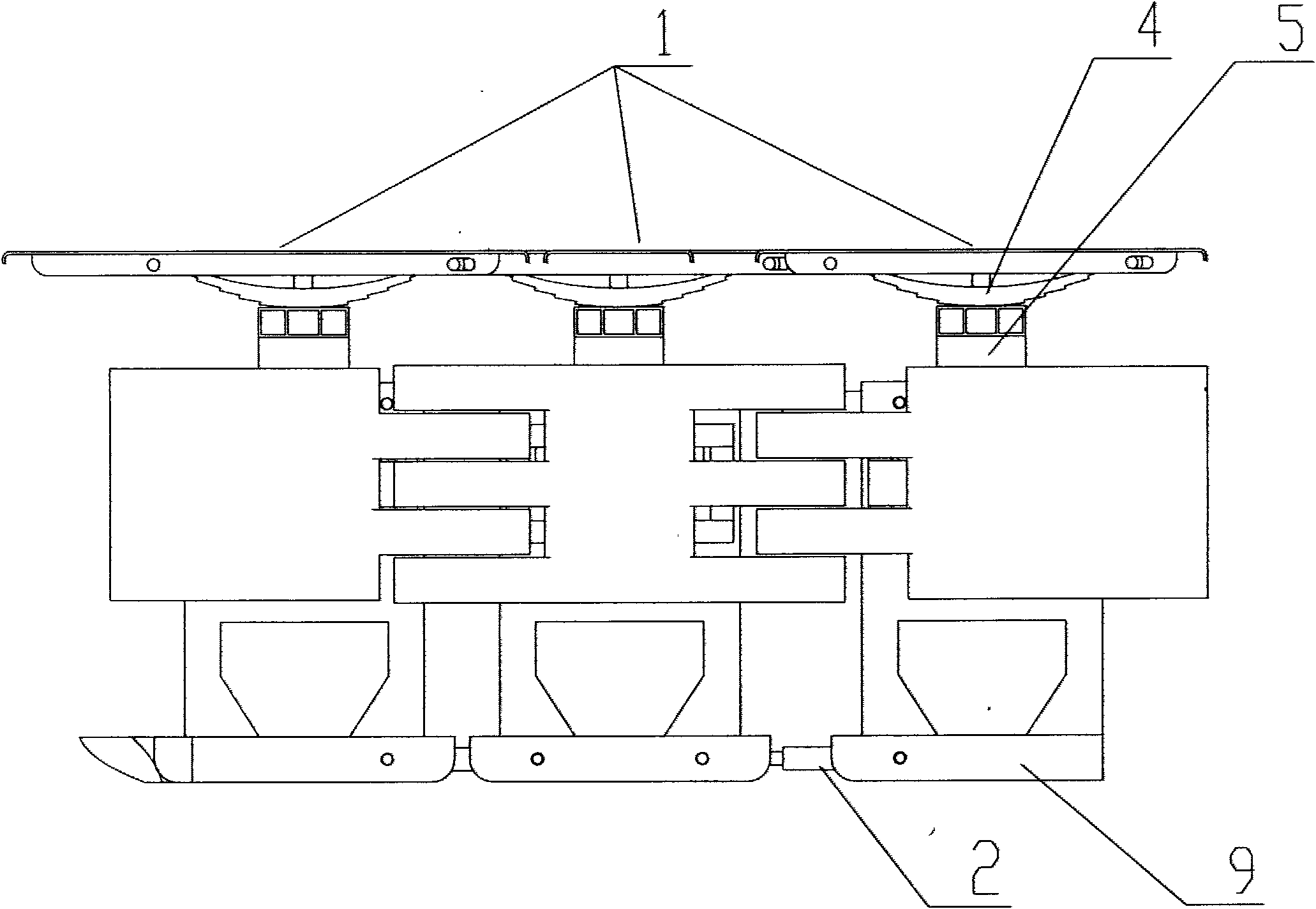

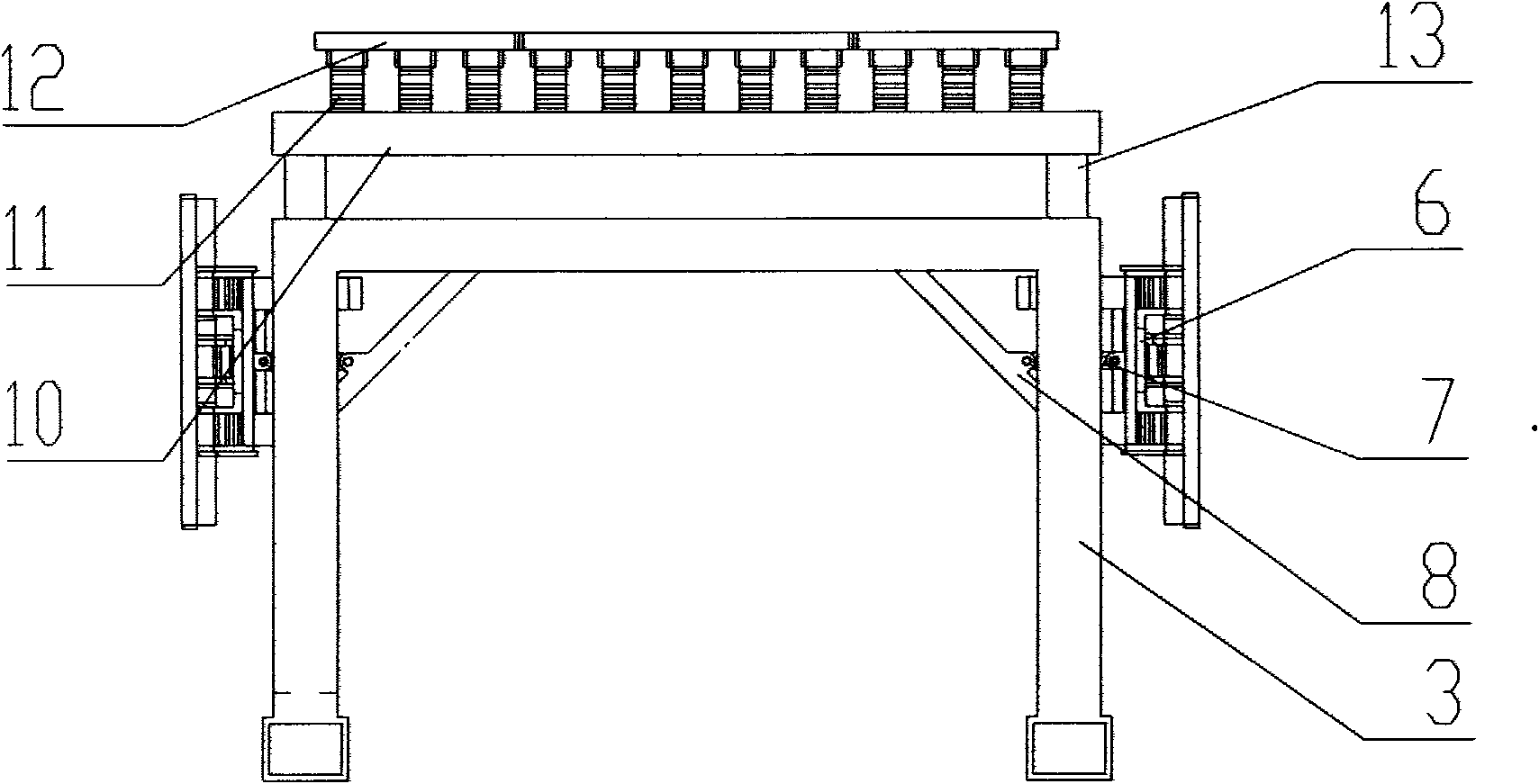

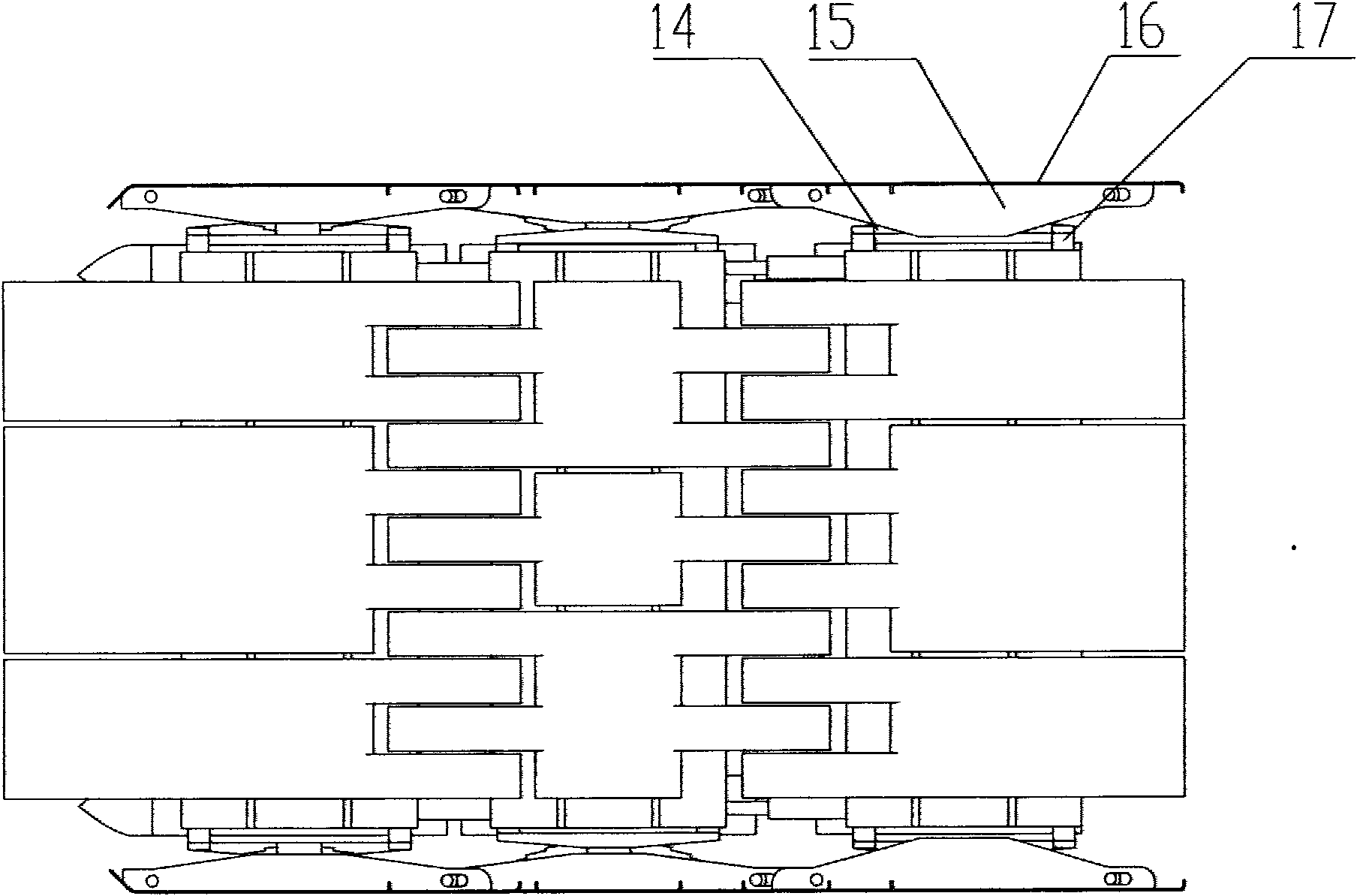

[0020] Such as figure 1 , figure 2 , image 3 As shown, the support is composed of several sub-supports 1, and the sub-supports 1 are connected by the frame-moving cylinders 2, and the sub-supports 1 are moved by the action of the frame-moving cylinders 2. Each sub-support is made up of main frame 3, top support frame 4, top support oil cylinder 5, side support frame 6, side support oil cylinder 7. The main frame 3 is a gantry frame structure, the top of the main frame 3 is provided with a slideway and an oil cylinder mounting seat, the two sides of the main frame 3 are provided with a slideway and an oil cylinder mounting seat 8, and the bottom of the main frame 3 is a walking shoe 9. Top support frame 4 is made up of crossbeam I10, leaf spring I11, top support plate 12, slide frame I13, top support frame 4 is installed on the top of main frame 3 by slideway, top support frame 4 and main frame 3 are supported by top support oil cylinder 5 Connected to each other, the carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com