Method for levelling and mounting base of mechanical equipment

A technology of mechanical equipment and installation method, which is applied in the direction of mechanical equipment, engine frame, supporting machine, etc., and can solve problems such as failure to meet high-precision level requirements, foundation cracking, and slurry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the method of the present invention will be described in detail with reference to the examples.

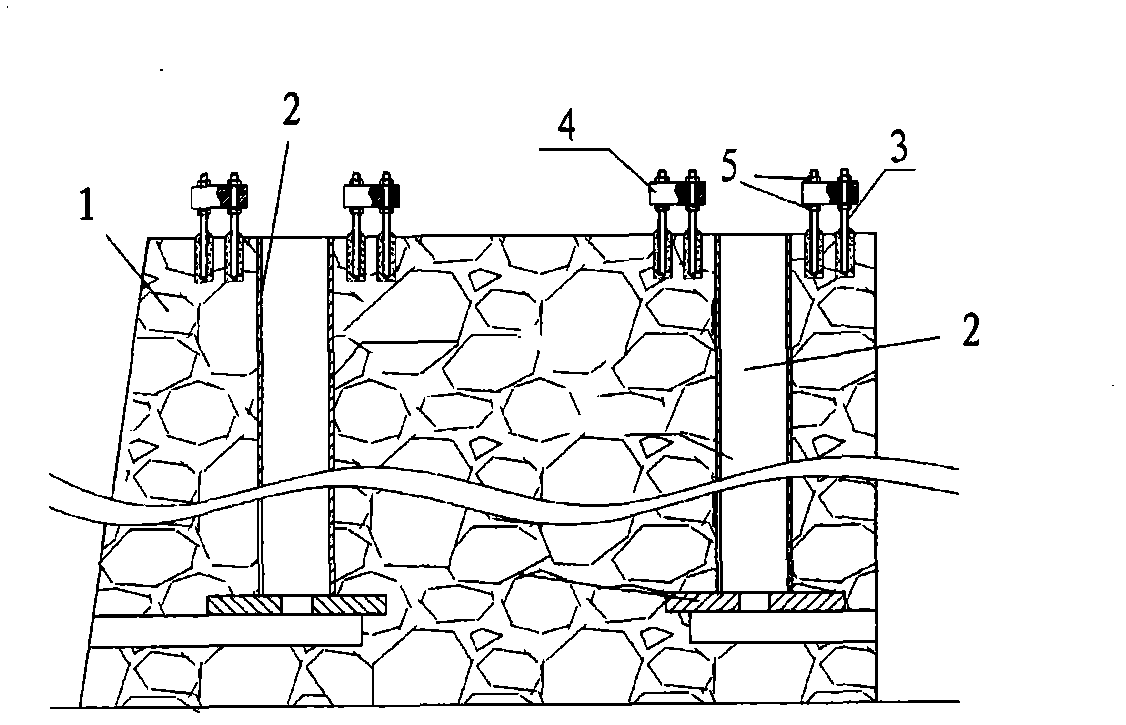

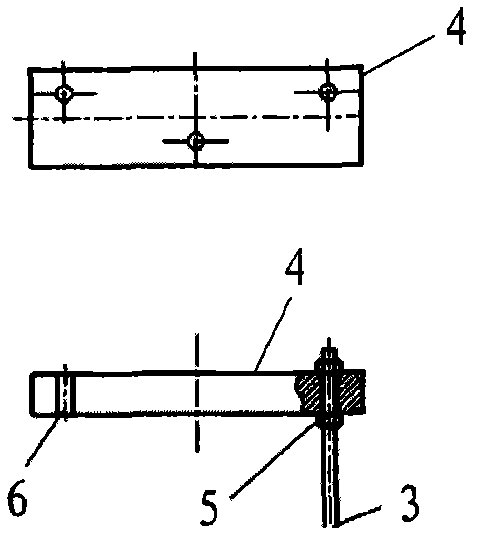

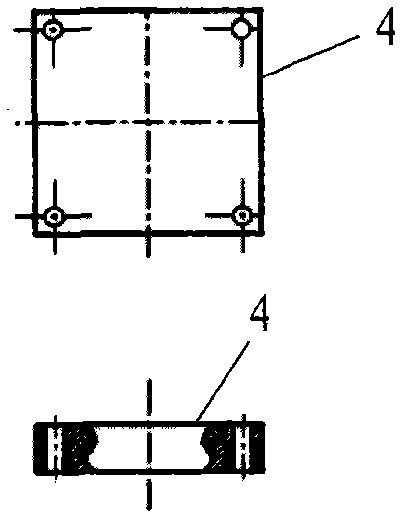

[0023] Exemplary embodiments of the present invention provide a leveling installation method for a mechanical equipment base. The mechanical equipment base is connected to the concrete foundation through a plurality of anchor bolts. The leveling installation method includes the following steps: a. On both sides of each anchor bolt, connect the pads to the concrete foundation through three or more bolts; b. Level all pads so that the The levelness is within 0.5mm / 1000mm and the levelness between all horns is within 1mm / 1000mm; c. Use fluid grouting material on the concrete foundation to carry out molding around each horn, so as to be in each ground A plurality of first casting bodies are formed on both sides of the foot bolts that expose the upper surface of the corresponding pad iron and surround and support the corresponding pad iron, and the contact area bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com