Method for drying powdery material by using vertical dryer

A technology for vertical dryers and powdery materials, which is applied in the directions of drying solid materials, heating to dry solid materials, drying, etc., which can solve the problems that powdery materials cannot be dried, extend the contact time, and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

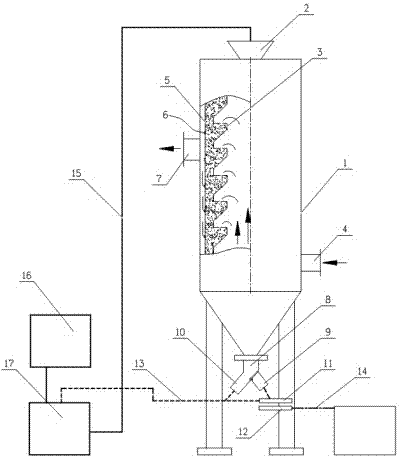

[0011] The used vertical dryer of the present invention has been partially improved on the basis of the existing vertical dryer, such as figure 1 As shown, it mainly includes a vertically arranged hollow cylinder 1, a feed inlet 2 is arranged on the top of the hollow cylinder, and a plurality of retaining rings 3 are arranged axially inside the hollow cylinder 1, so that the hollow Two concentric cavities, inner and outer, are formed in the cylinder body 1, and a space is left between two adjacent retaining rings 3 to form a hot air outlet. The lower part of the hollow cylinder body 1 is provided with an air inlet 4 for connecting a heat source. The air inlet 4 is directly communicated with the inner cavity surrounded by the material retaining rings 3 , so that hot air is directly sent into the cavity surrounded by the material retaining rings 3 and blown out from the space between the material retaining rings 3 . The cylinder wall of the hollow cylinder 1 is a sandwich struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com