Using method of closed-type discharging device

An unloading device and sealing type technology, applied in the field of unloading devices, can solve the problems of poor sealing performance, unsuitable star-shaped ash extractor, etc., and achieve the effects of reducing extrusion, increasing shear stress and preventing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure and use method of a sealed unloading device will be described in detail below through specific embodiments.

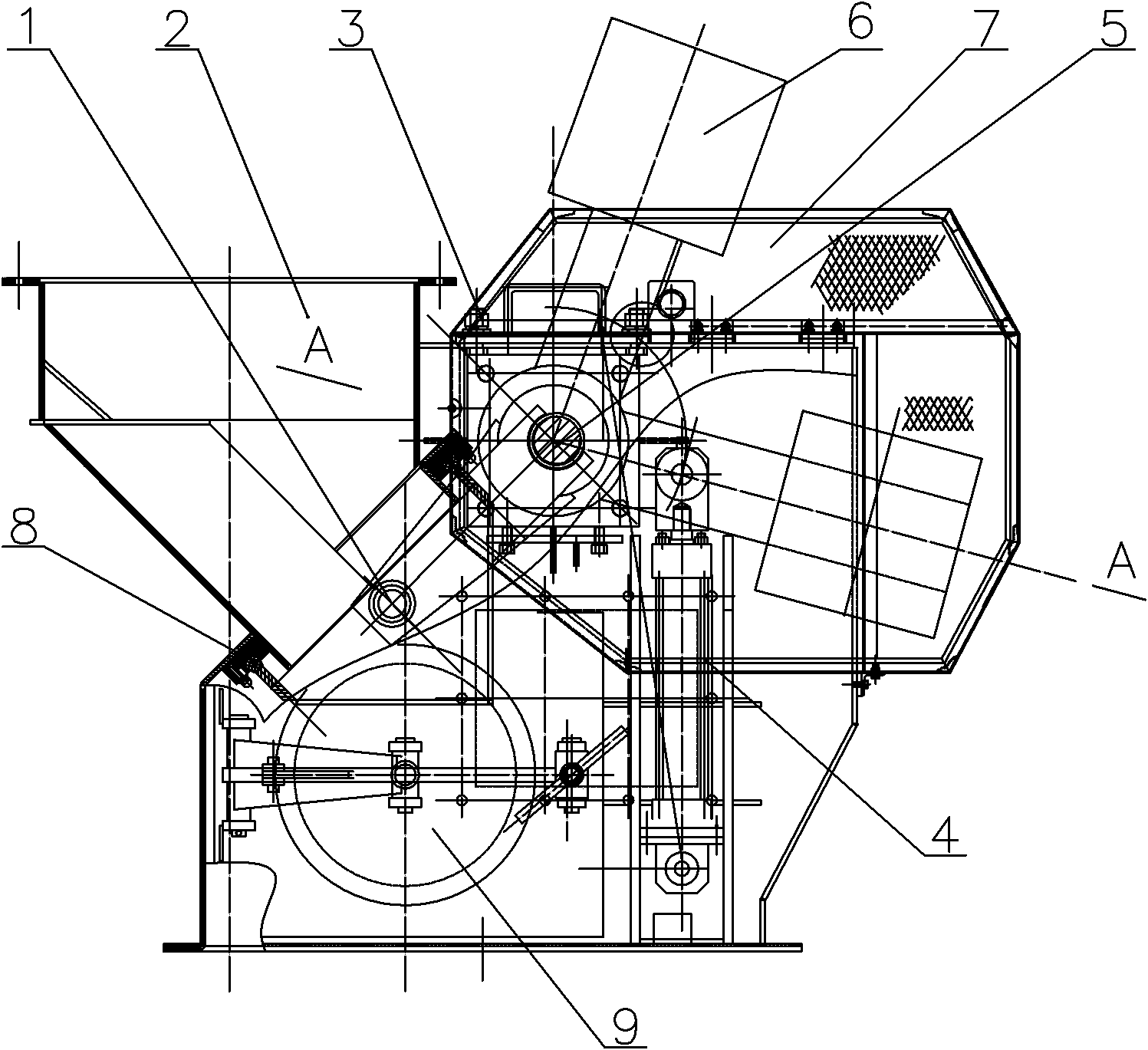

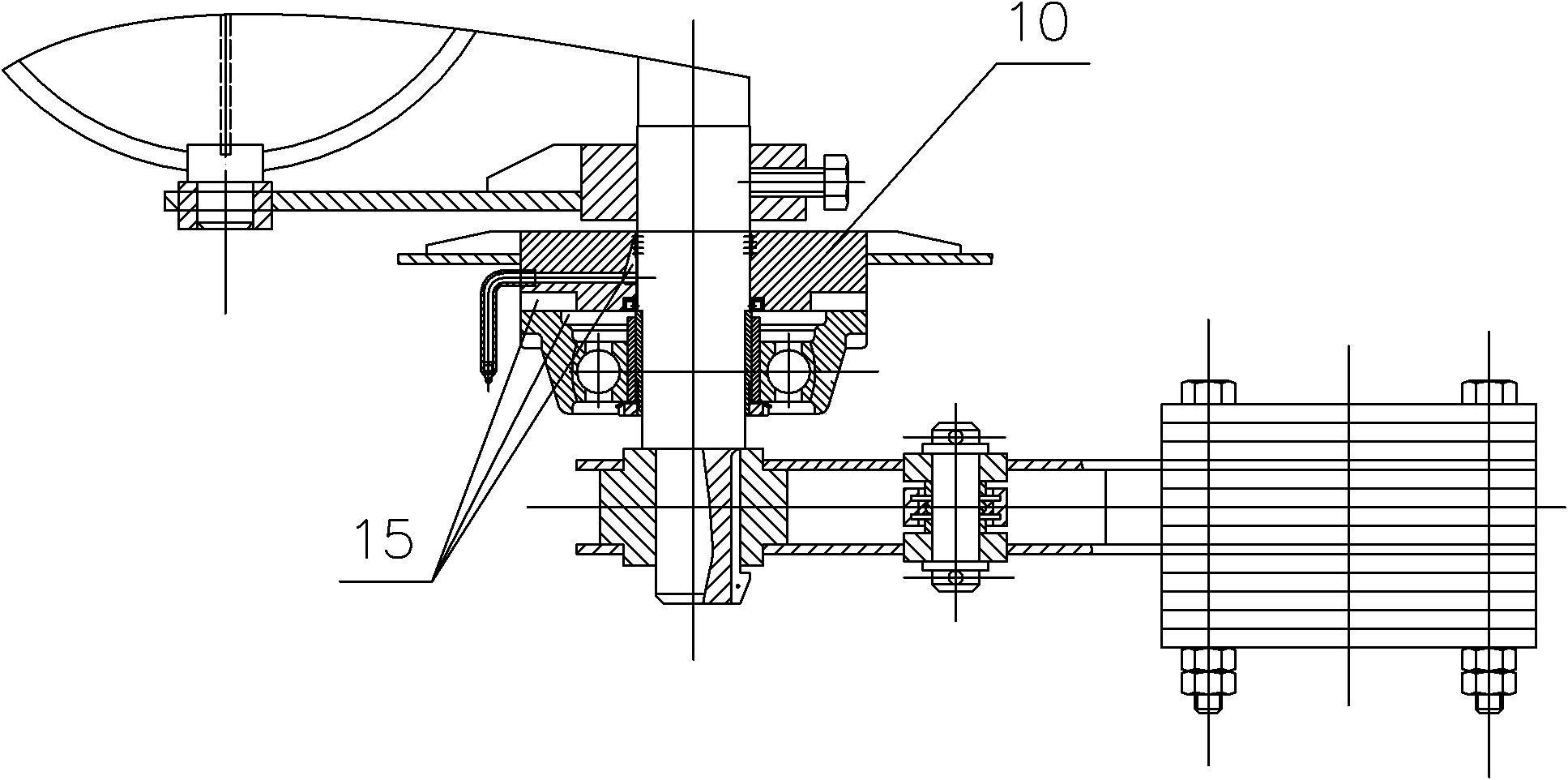

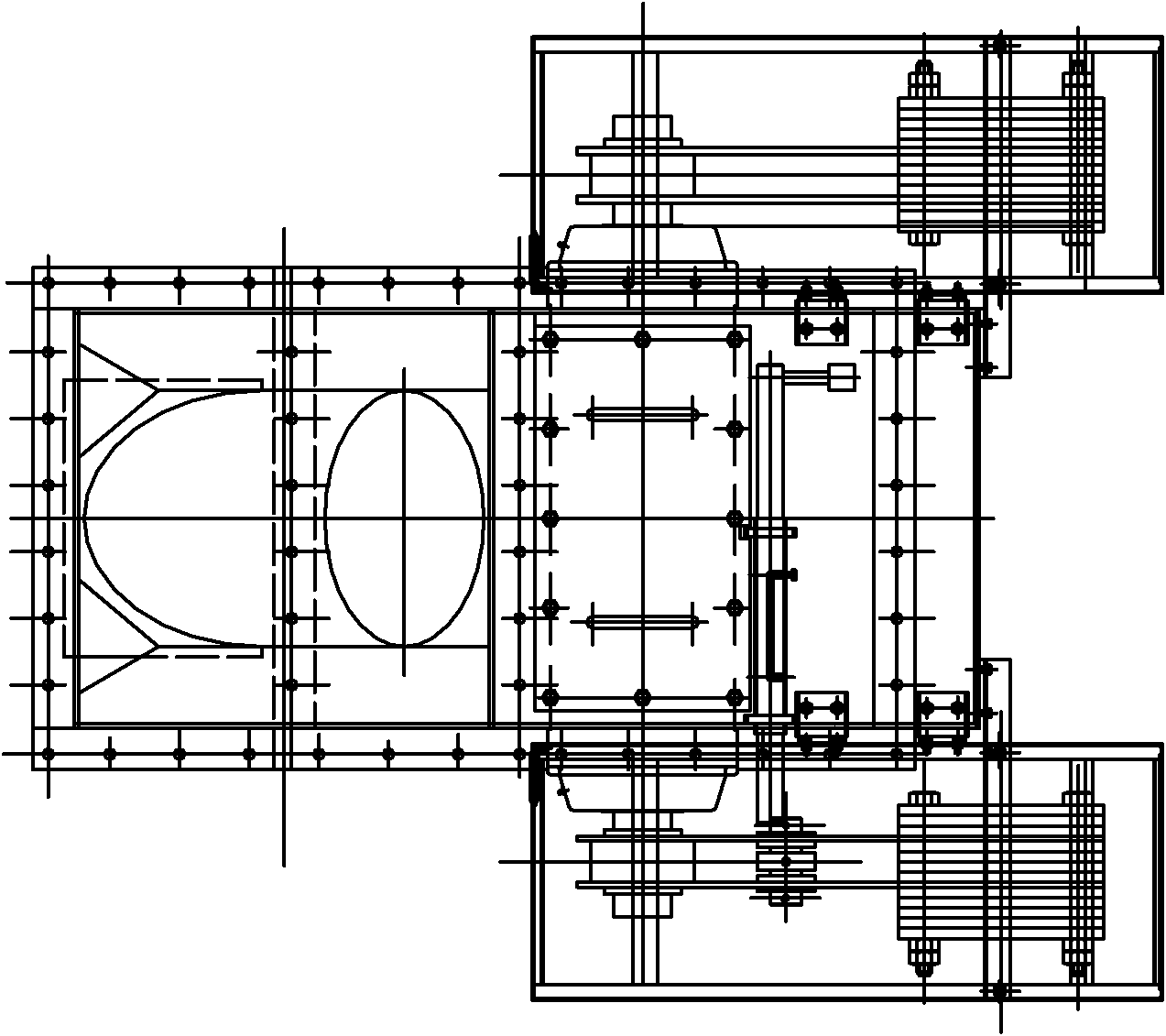

[0027] See figure 1 , figure 2 , image 3 , a sealed unloading device, including a discharge spout door 1, a box body 2, a cover plate 3, an oil cylinder 4, a bearing with a seat 5, a counterweight rod 6, a protective cover 7, a sealing ring 8, a single rotating door 9, The isolation seat 10 and the integral bearing are arranged on the outside of the box body 2 and are isolated with the isolation seat 10 between the box body, and the isolation seat 10 is provided with a dust discharge channel 15 . This structure allows the leaked dust to be discharged through this channel without entering into the bearing. A labyrinth sealing structure and a sealing ring are adopted between the isolation seat 10 and the rotating shaft. A silicone rubber sealing ring 8 is provided at the contact portion between the blanking spout door 1 and the box body 2 . An...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com