Temperature compensation method for pressure sensor

A technology of pressure sensor and temperature compensation, which is applied in the direction of measuring fluid pressure, instruments, measuring force, etc., to achieve the effects of improving measurement accuracy, easy operation, and avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Referring to the accompanying drawings, the present invention will be described in detail below.

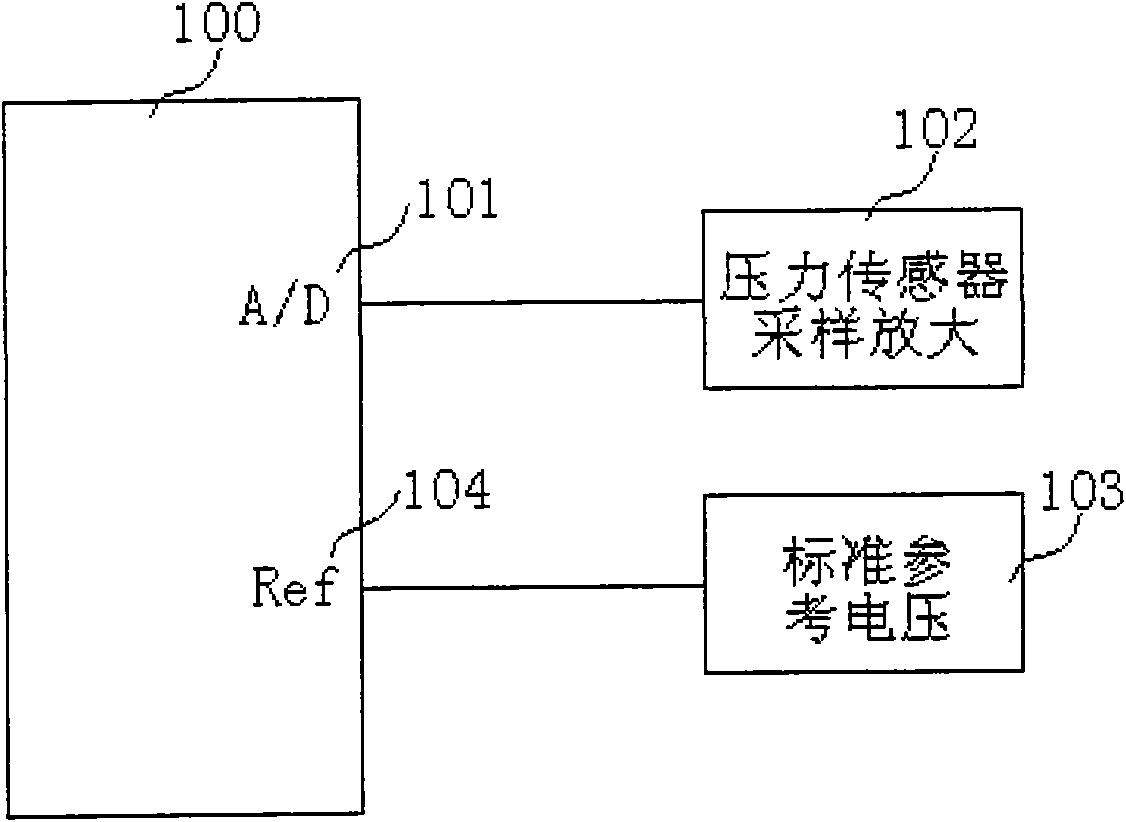

[0054] like figure 1 As shown, the traditional pressure sensor outputs an analog voltage value after sampling and amplifying (102). In the digital measurement system, it is first converted into a digital signal through the A / D port (101) of the microprocessor (100). In addition, it is necessary to introduce a The standard reference voltage (103) is connected to the Ref reference terminal (104) of the microprocessor (100).

[0055] In this sampling channel, the pressure sensor sampling amplification (102), A / D port (101), and standard reference voltage (103) are coupled together, and the accuracy, static characteristics, and dynamic characteristics of the three are finally expressed as the error of the entire sampling channel characteristic. And all three have the problem of temperature drift. Therefore, the three and the temperature sensor are integrated in one module to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com