Epoxy resin pouring type voltage transformer

A voltage transformer, epoxy resin technology, applied in the direction of inductors, transformers/inductor shells, transformers, etc., can solve problems such as explosion, and achieve the effects of reducing production costs, convenient assembly, and strong processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

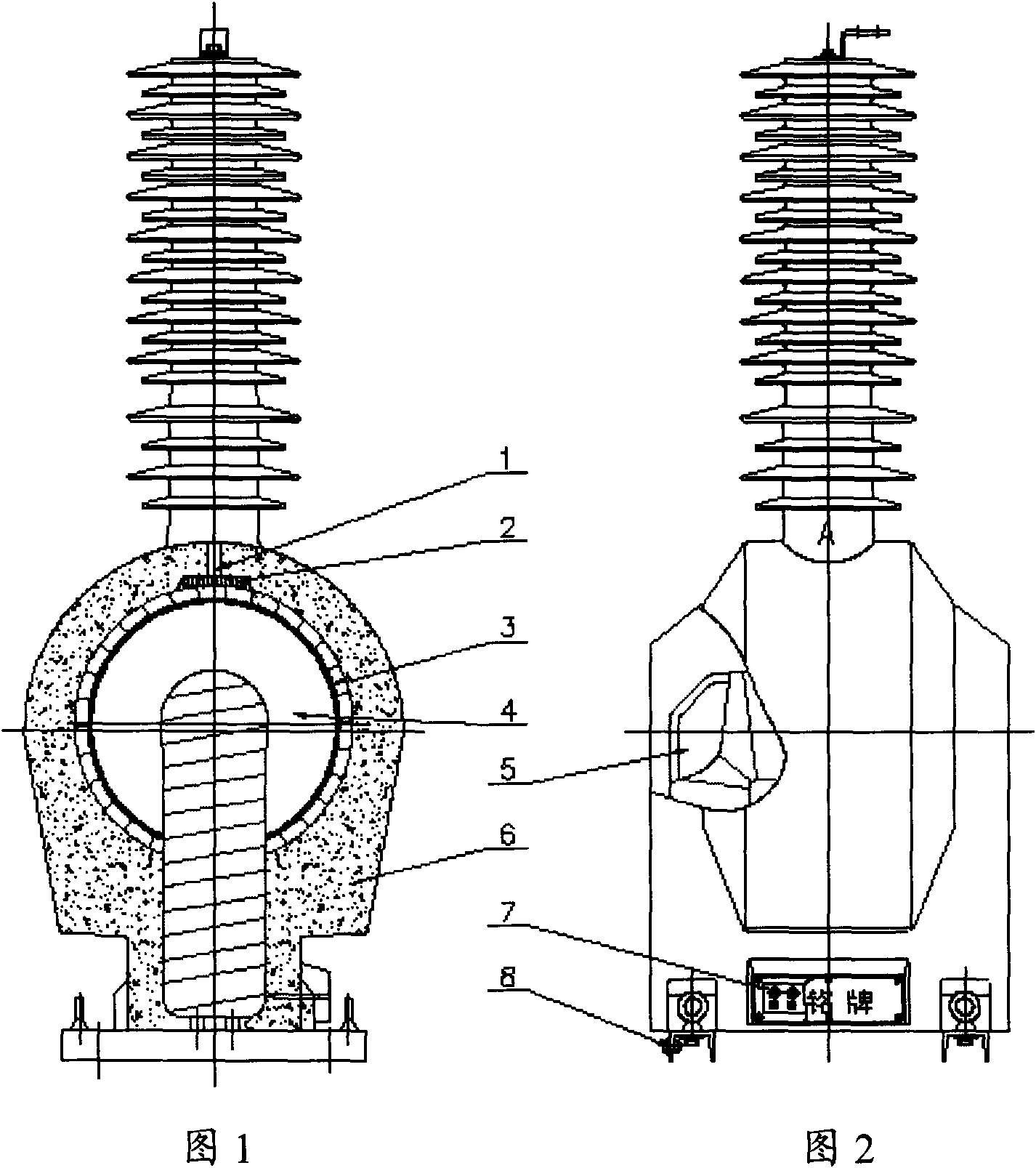

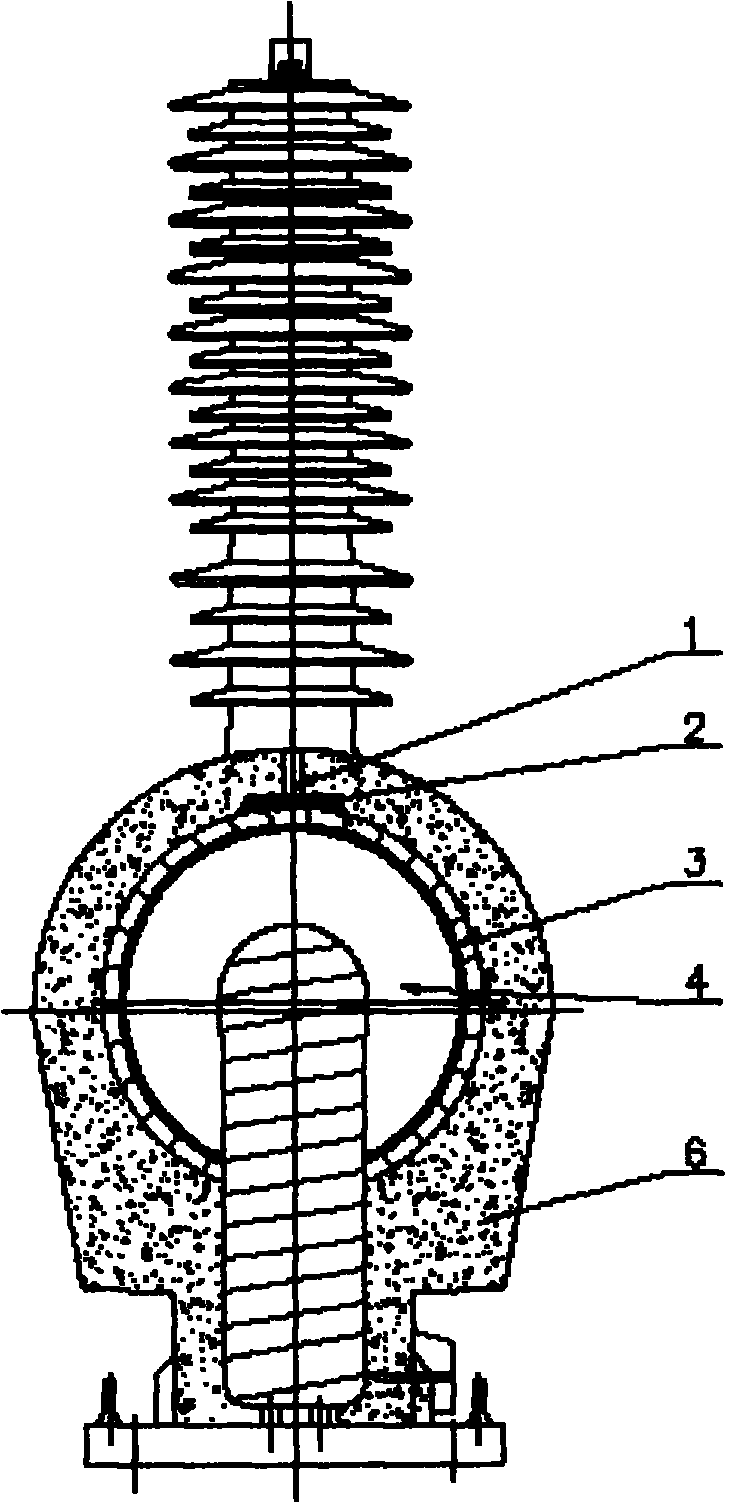

[0009] figure 1 It is a full sectional view of an epoxy resin casting type voltage transformer of the present invention. The epoxy resin casting type voltage transformer includes a primary terminal 1, a voltage equalizing ring 2, a shielding ring 3, a winding 4, an iron core 5, an epoxy resin Housing 6, secondary terminal 7, mounting channel steel 8; wherein: the epoxy resin housing 6 includes a cylindrical container and a base, the cylindrical container and the base of the epoxy resin housing 6 are made of The overall structure is made of epoxy resin; there is a pair of mounting channel steel 8 under the base of the epoxy resin housing 6; the interior of the cylindrical container of the epoxy resin housing 6 is equipped with a primary terminal 1 and a pressure equalizing ring 2. Shielding ring 3, winding 4, iron core 5; the primary terminal 1 is located on the top of the cylindrical container of the epoxy resin shell 6; the root of the primary terminal 1 is connected to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com