Conductive connecting sheet with side composite metal structure and production method thereof

A technology of conductive connecting piece and composite metal, which is applied in the field of conductive connecting piece with side composite metal structure and its production, to reduce recycling costs, meet the requirements of high conductivity and transition welding parts, and improve the value of waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The original product is designed as a straight bar-shaped pure nickel conductive connection piece with a thickness of 0.4mm, a width of 4mm, a total length of 50mm, and a hardness of 1 / 4.

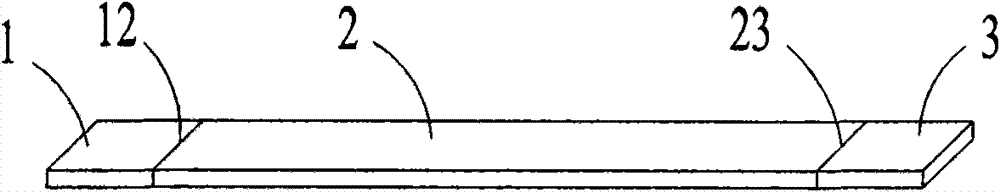

[0037] See figure 1 , with a nickel / copper / nickel side composite metal structure. This section of nickel conductive connecting piece has a copper strip conductor 2, and the two ends of the copper strip conductor 2 in the longitudinal direction are symmetrically and firmly bonded with nickel welding parts 1 and 3, the copper strip conductor 2 and the nickel A bonding surface 12 that is closely joined is formed between the welding parts 1, and another bonding surface 23 that is tightly joined between the copper strip conductor 2 and the nickel welding part 3 is formed. The cross section of the copper strip conductor 2, The cross-sections of the nickel welded portions 1 and 3 are both rectangular. Wherein, the material structure of the joint surfaces 12 and 23 is dense. The thickness...

Embodiment 2

[0045] The original design is a semi-hard pure copper conductive connection piece with a thickness of 0.4mm, a width of 4mm and a length of 50mm.

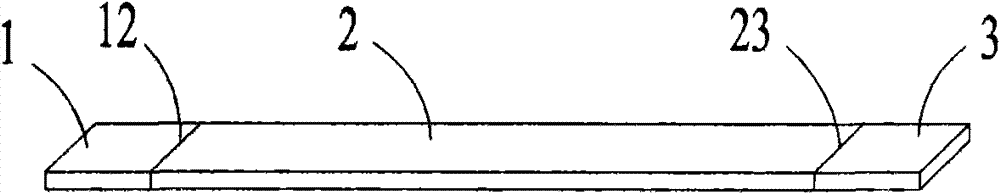

[0046] See Example 2 for the copper conductive connection piece figure 2 , with a copper / aluminum / copper side composite metal structure. The copper conductive connecting piece has an aluminum strip conductor 2, and copper welding parts 1 and 3 are symmetrically and firmly bonded to both ends of the aluminum strip conductor 2 in the longitudinal direction. The aluminum strip conductor 2 and the copper A joint surface 12 is formed between the welding parts 1 and the other joint surface 23 is formed between the aluminum strip conductor 2 and the copper welding part 3. The cross section and the cross section of the copper welding parts 1 and 3 are all rectangular. The thickness and width of the copper welding parts 1 and 3 are the same as the thickness and width of the aluminum strip conductor 2 .

[0047] Its preparation process i...

Embodiment 3

[0054] A pole lug (which can also be understood as a conductive connecting piece) used in an aluminum-shell lithium-ion battery is a straight bar-shaped element (0.15mm*3mm*40mm, thick *W*L) or aluminum / nickel lap joint type transfer sheet (the thickness of aluminum strip and nickel strip is 0.15mm, the width is 3mm, the length of aluminum strip is 36mm, the length of nickel strip is 10mm, and the overlapping length of the two materials is 6mm) ,

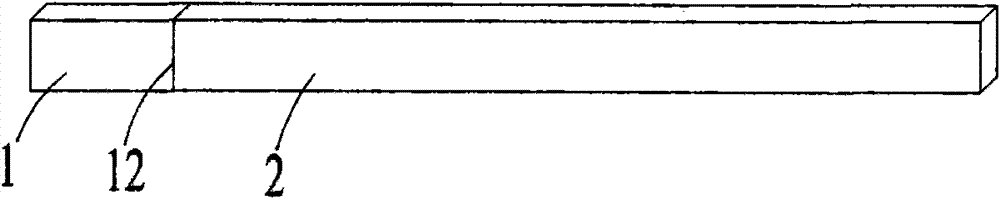

[0055] Embodiment 3 is a tab (or understood as a conductive connecting piece) using the aluminum-nickel side composite structure of the present invention, refer to image 3 . The tab has an aluminum strip conductor 2, and a nickel welding part 1 is firmly bonded to one end surface of the aluminum strip conductor 2 in the longitudinal direction. The aluminum strip conductor 2 and the nickel welding part 1 are formed between the aluminum strip conductor 2 A joint surface 12 that is closely joined, the cross-section of the aluminum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com