Over-temperature and over-current double protection element and manufacturing method thereof

A dual-protection, overcurrent technology, applied in the protection, electrical components, emergency protection circuit devices that respond to overcurrent, etc., can solve the problems of control IC failure, power consumption, long PTC component action time, etc., to achieve accelerated cut-off time, provide overcurrent protection, make up for the effect of slow action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with accompanying drawings.

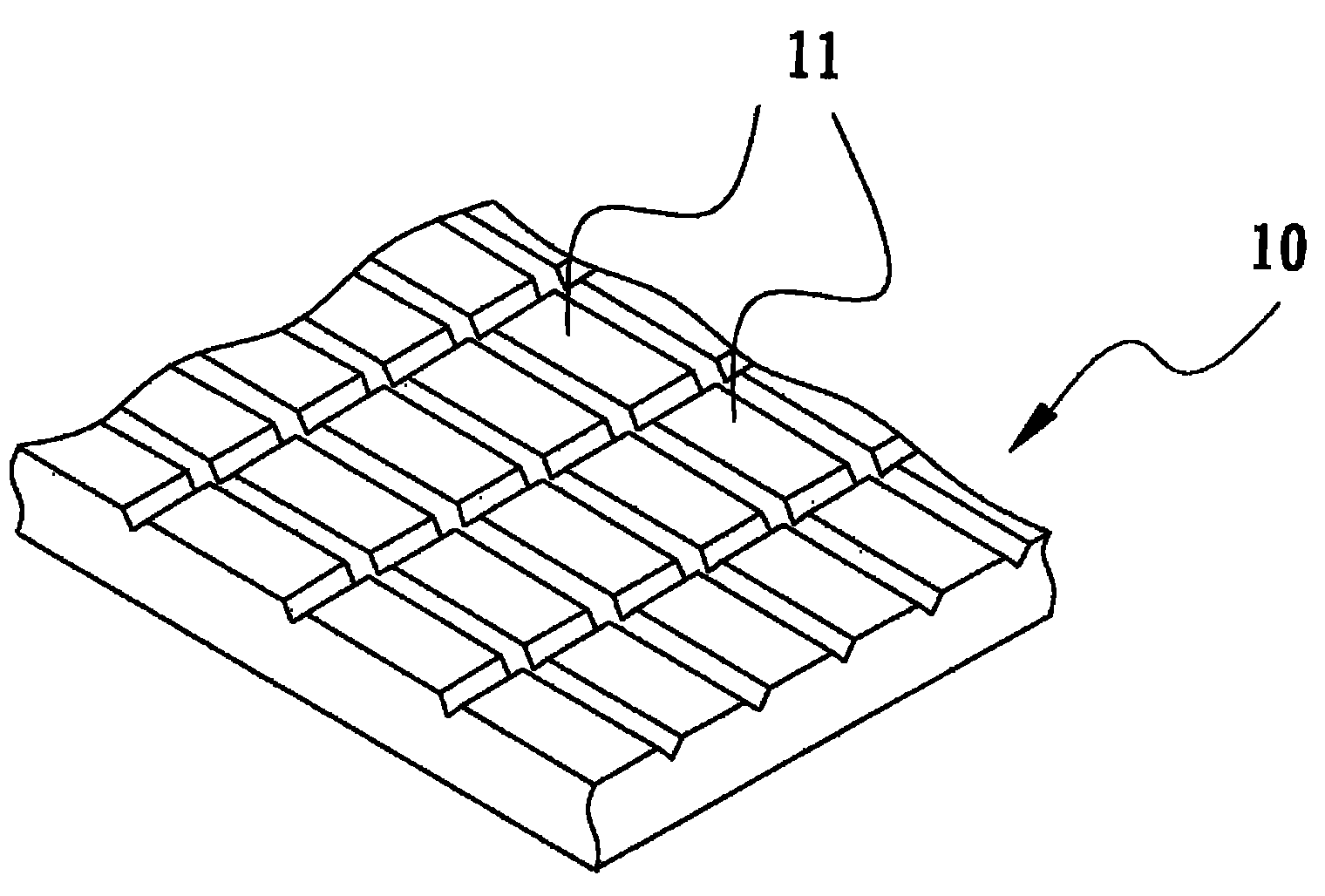

[0030] The double protection element of the first preferred embodiment of the present invention is to choose to adopt such as figure 1 The shown ceramic substrate 10 has no electrical or thermal conductivity because its material is not a good conductor of electricity or heat. In this example, a plurality of units are distributed in an array on the ceramic substrate 10 , and each unit is illustrated as a rectangular substrate unit body 11 , the short side direction is defined as the row direction, and the long side direction is defined as the column direction. And for the sake of simplicity, only the structure of a single unit is shown in the following diagrams illustrating the flow.

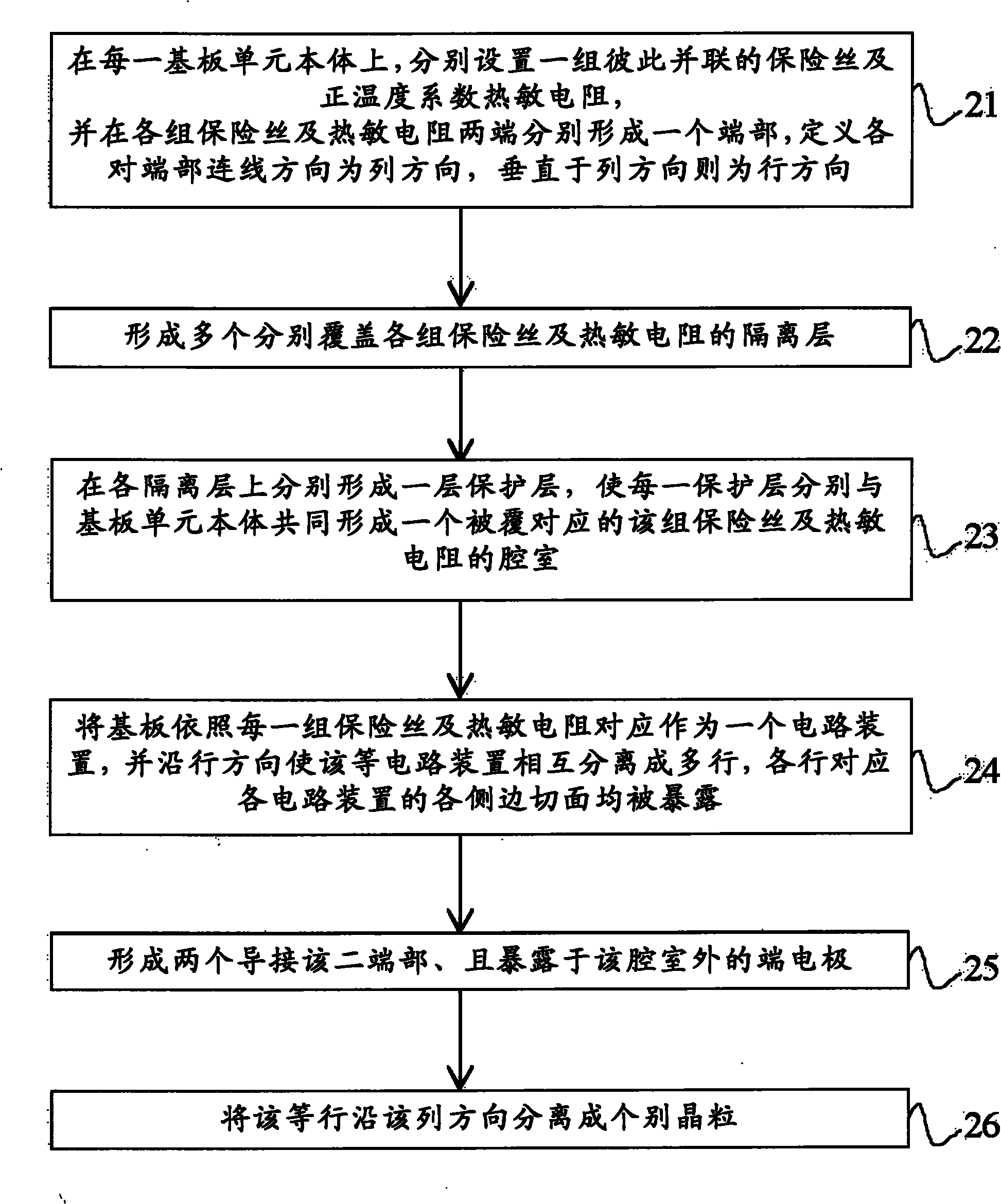

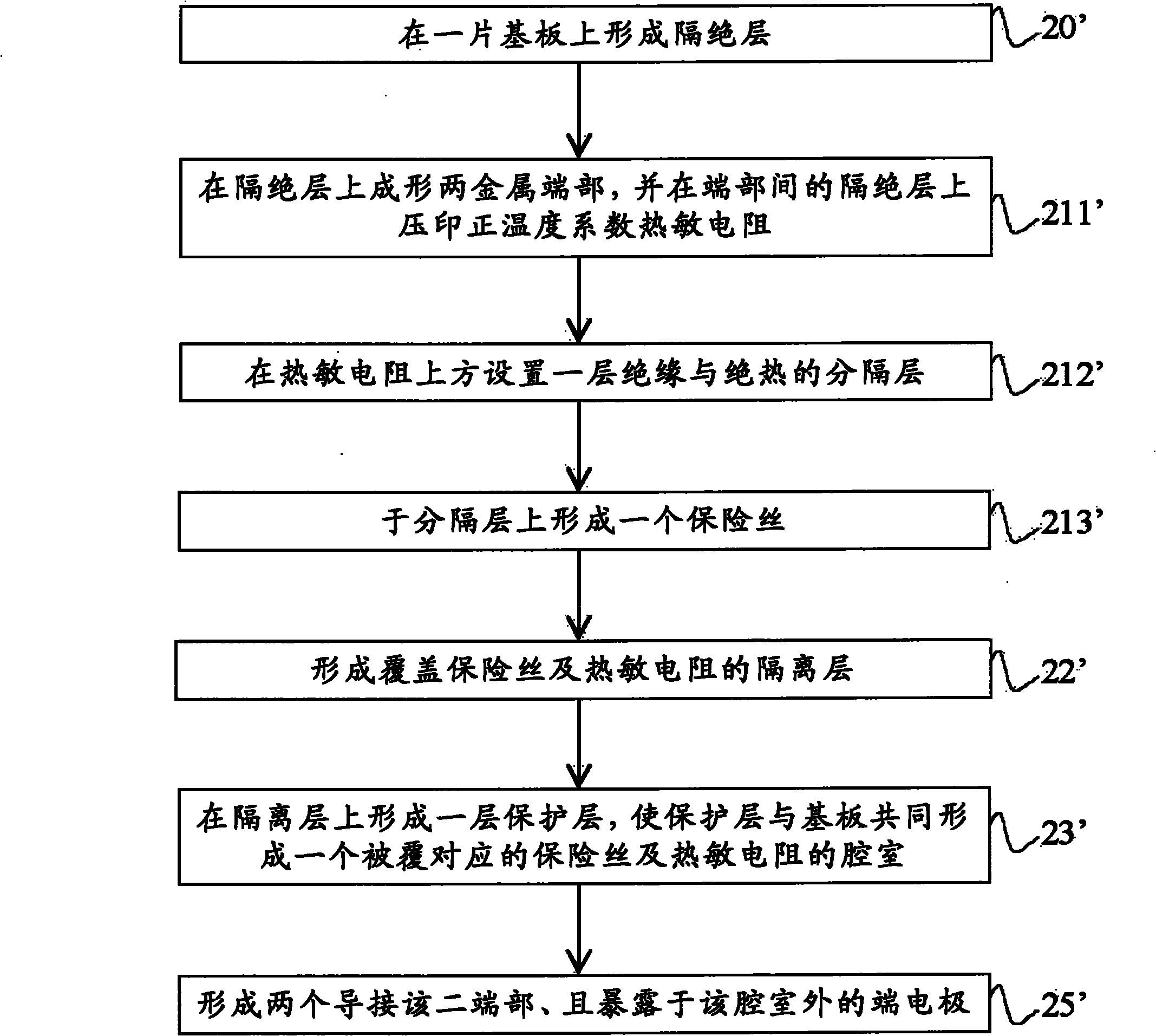

[0031] The manufacturing process of the first preferred embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com