Spraying robot mechanism

A spraying robot and rotary mechanism technology, applied in the direction of spraying devices, etc., can solve the problems of large inertia, heavy arms, poor rigidity, etc., and achieve the effect of simple structure, good dynamic performance, and small motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing and embodiment:

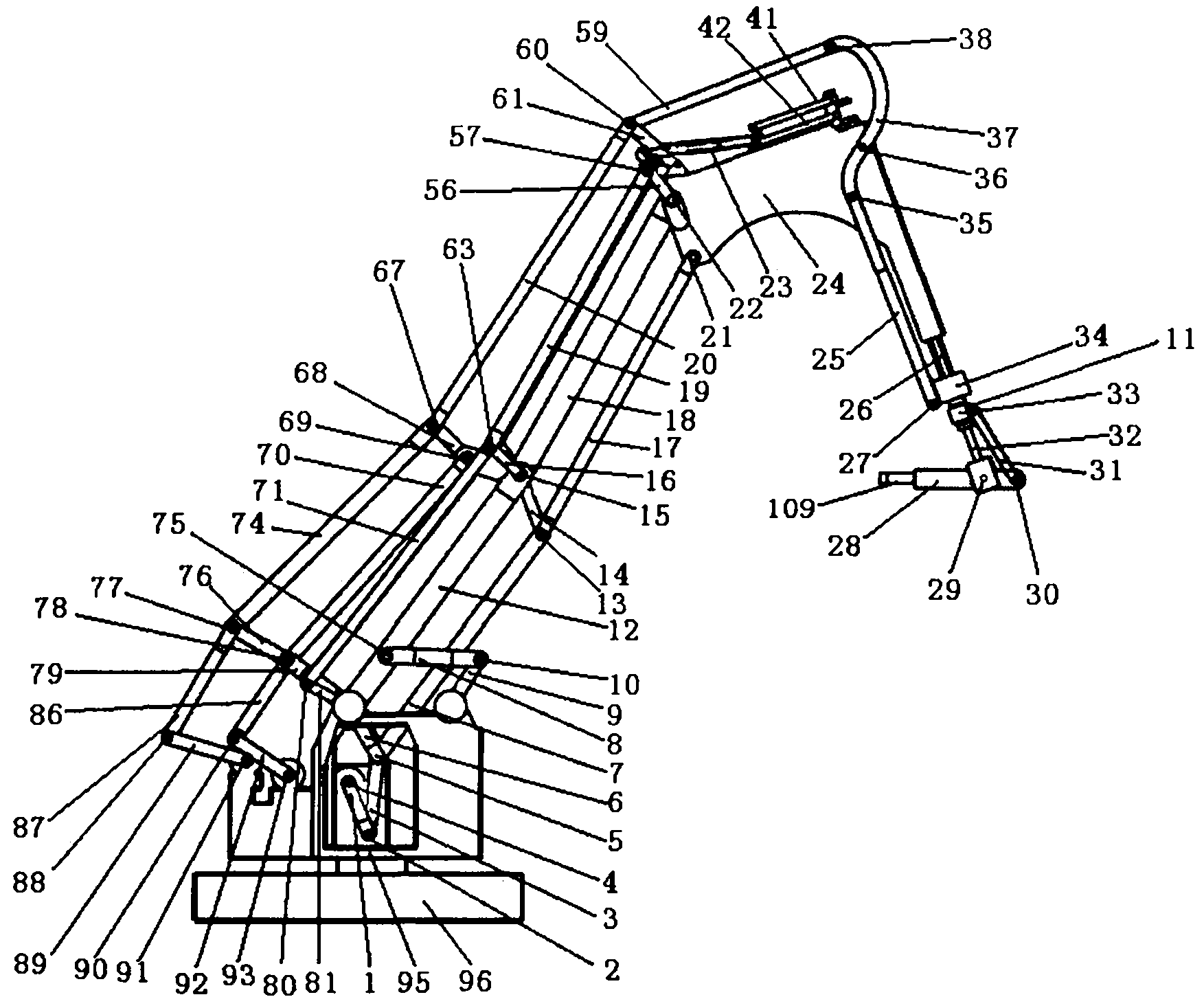

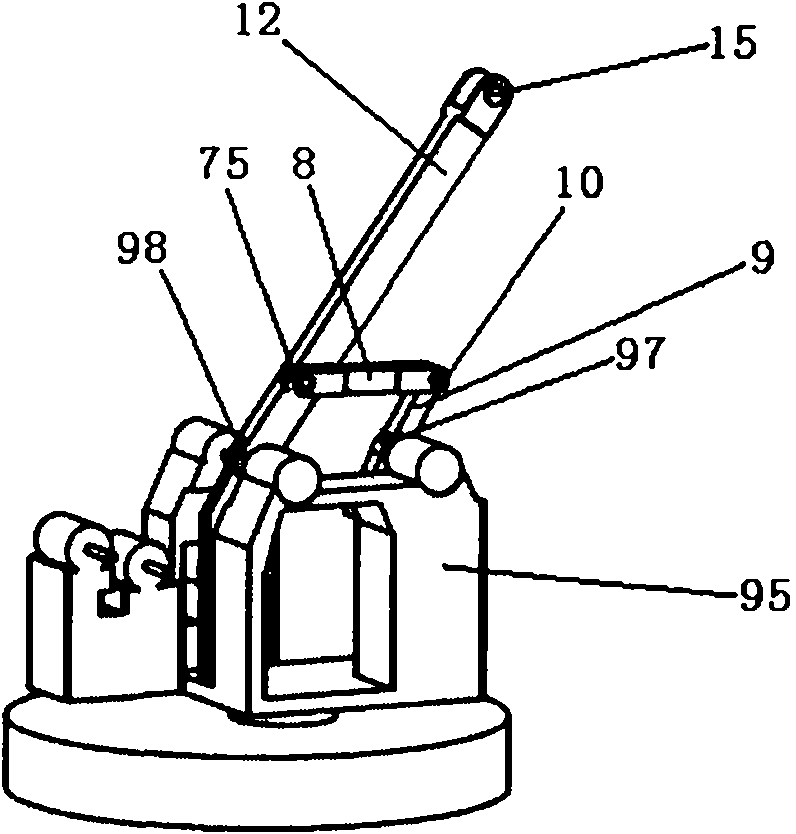

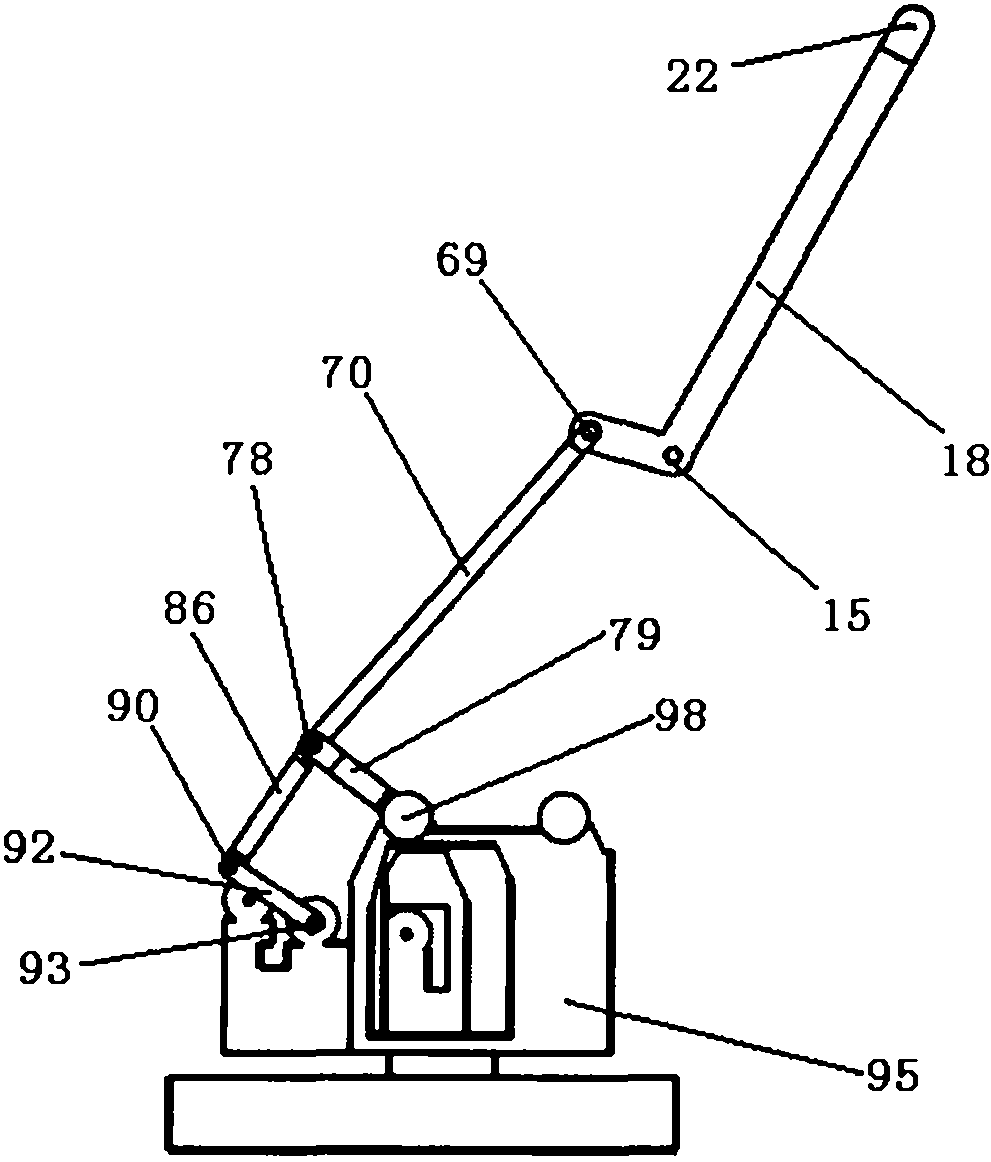

[0028] control figure 1 , 7 , 8, 9, 10, 11, a spraying robot mechanism, including a waist rotary mechanism, a shoulder rotary mechanism, an elbow rotary mechanism, a wrist twist mechanism, a spray gun base bending mechanism, a frame 95 and a rotary platform 96. The frame 95 is installed on the rotary platform 96 to realize the flexible movement of the entire robot working space at any position.

[0029] control figure 1 , 2 , 11, the waist turning mechanism is formed by connecting the first active rod 9, the sixth connecting rod 8, the waist rod 12 and the frame. One end of the first active rod 9 is connected to the frame through the eighth rotating pair 97, the other end is connected to the sixth connecting rod 8 through the ninth rotating pair 10, and the other end of the sixth connecting rod 8 is connected to the waist through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com