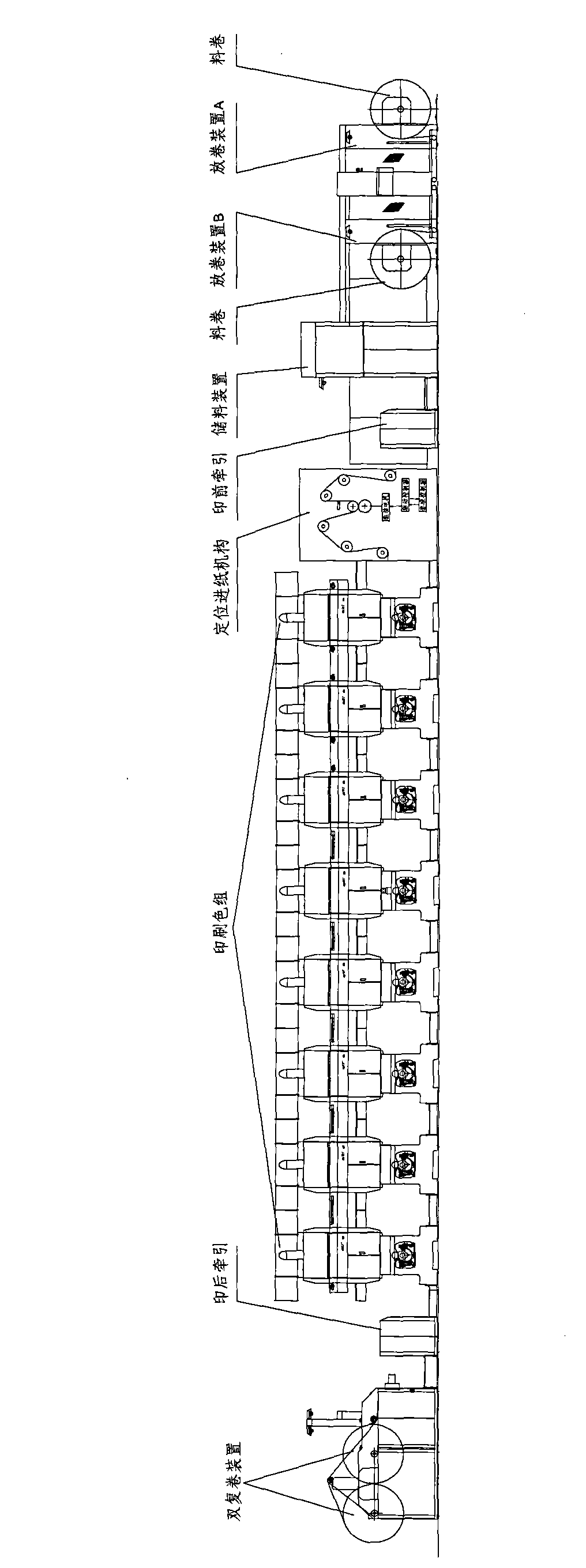

Rotary intaglio printing press with positioned printing function

A technology of gravure printing machine and printing machine, which is applied in printing machine, rotary printing machine, gravure rotary printing machine and other directions to achieve the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

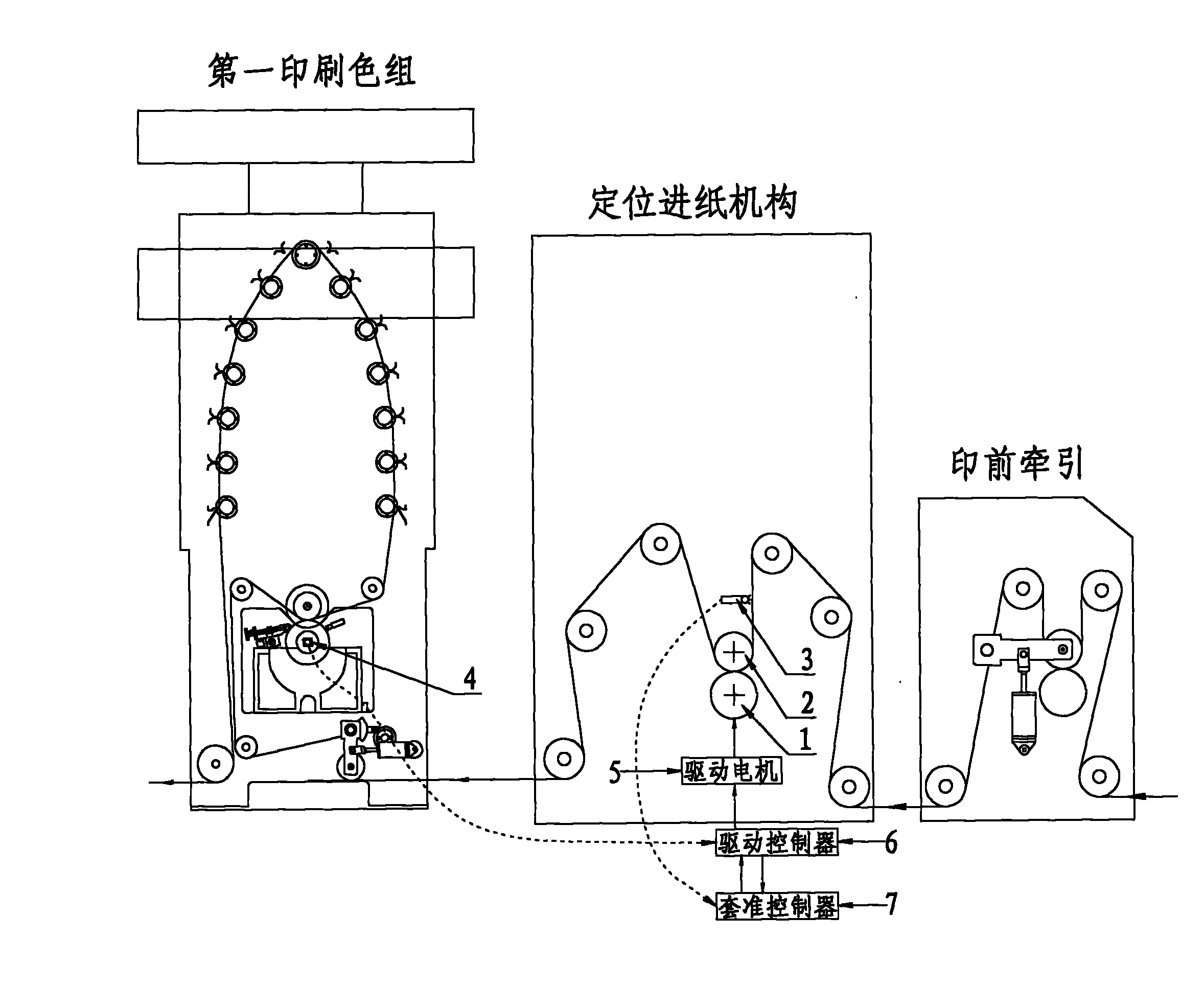

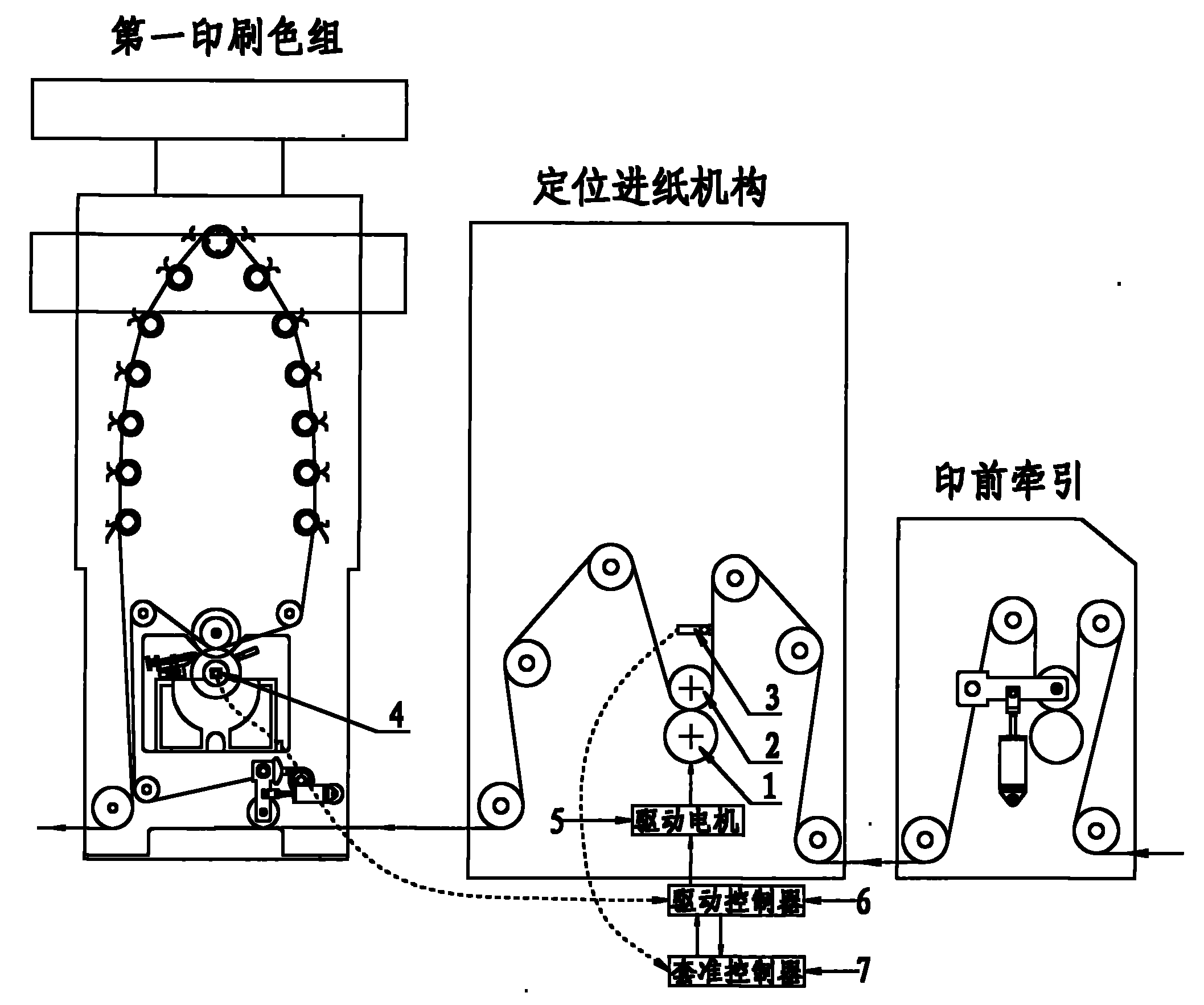

[0010] In the figure, it can be seen that the positioning paper feeding mechanism is set between the prepress traction and the first printing color group. When the paper with text and pattern information enters the positioning paper feeding mechanism from the prepress traction, the photoelectric eye 3 To detect and feed back the information to the registration controller 7, and at the same time the encoder 4 is also taking a signal to the drive controller 6 in the printing color group, and the drive controller 6 transmits the data to the registration controller 7 after calculation. The registration controller 7 compares the data of the photoelectric eye 3 and the encoder 4, calculates the error between the existing text and pattern information and the first color printing, and then transmits it to the drive controller 6, through the drive control The device 6 controls the driving motor 5 to drive the steel roller 1 and the rubber roller 2 for real-time and accurate compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com