System and method for preventing gliding during secondary lifting of crane

A crane and gravity technology, applied in the direction of clockwork mechanism, load hanging components, hoisting device, etc., can solve the problems of secondary lifting and sliding, pressure fluctuation, secondary lifting and sliding, etc., and achieve The hoisting operation is simple and reliable, reducing the possibility of accidents and eliminating the effect of secondary lifting and sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

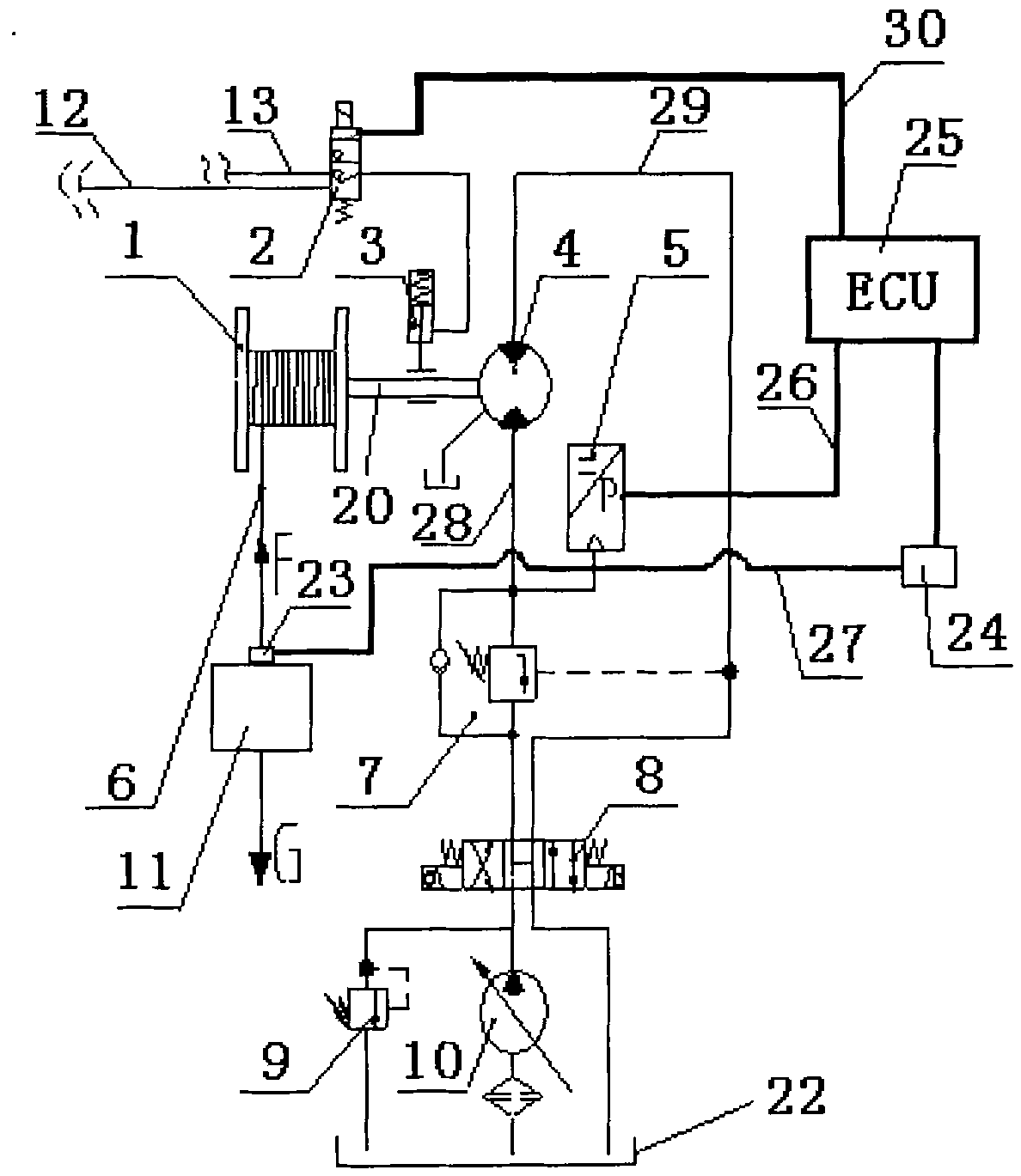

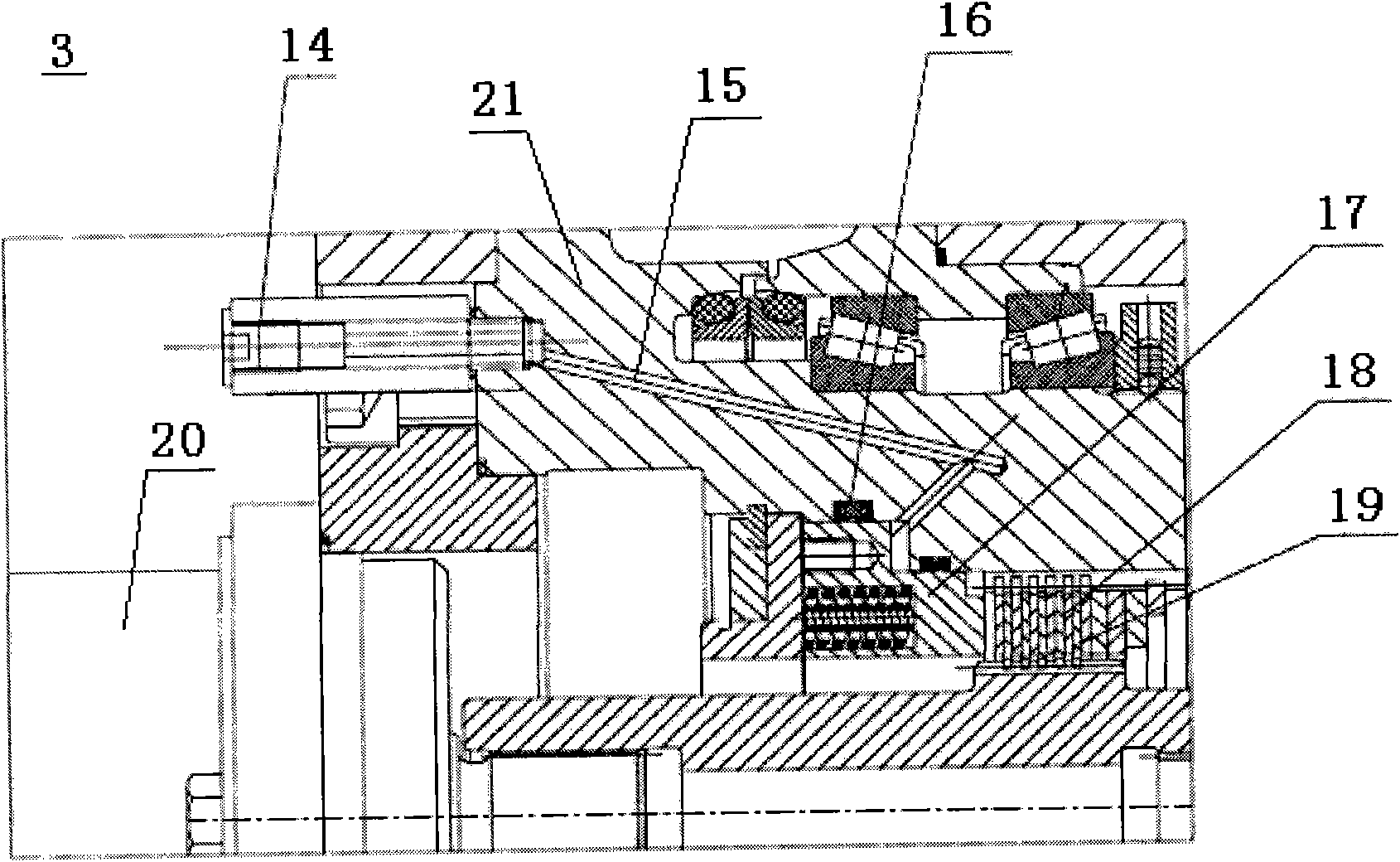

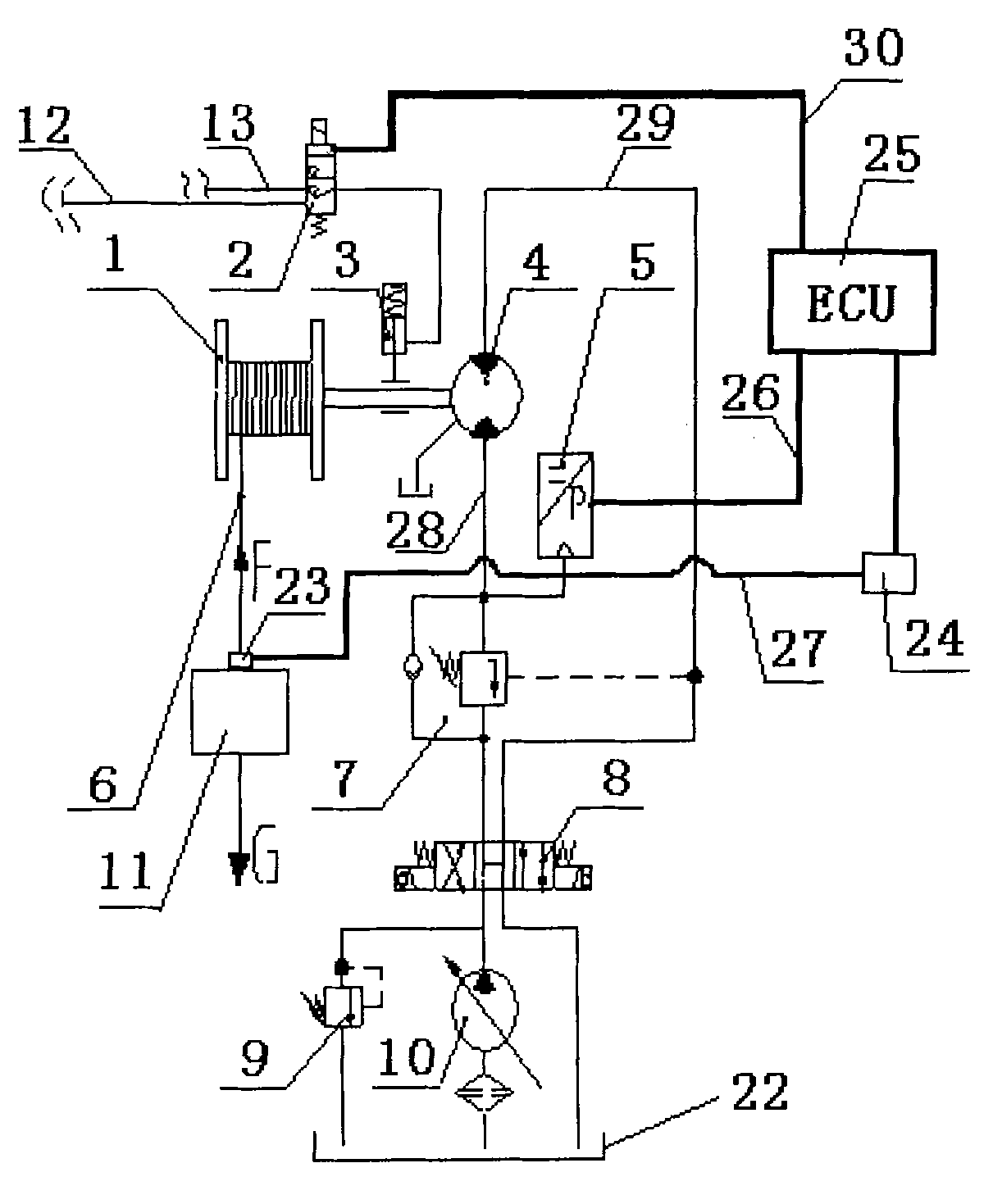

[0039] Preferred embodiments of the present invention will be described below focusing on the accompanying drawings. What needs to be explained here is that, figure 1 and figure 2 The shown anti-secondary lifting and sliding system is a preferred embodiment of the present invention, but the present invention is not limited to the preferred embodiment shown in the accompanying drawings. Therefore, before describing the preferred embodiments of the present invention, it is necessary to first explain the basic technical solution of the present invention.

[0040] From the perspective of the working status of the crane's secondary lifting, the effective way to solve the problem of the crane's secondary lifting and sliding is to establish a real-time detection anti-secondary lifting and sliding system. Detect the load gravity G and the lifting driving force F accurately, and compare the increasing lifting driving force F with the load gravity G, and release the brake 3 only when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com