Die molding gel

A technology with the following percentages by weight, applied in the field of molding plastics, can solve the problems of working effect, lack of production cost, etc., and achieve the effect of low production cost, reasonable formula and good use effect.

Inactive Publication Date: 2011-05-04

范井明

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing molding plastics are deficie

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

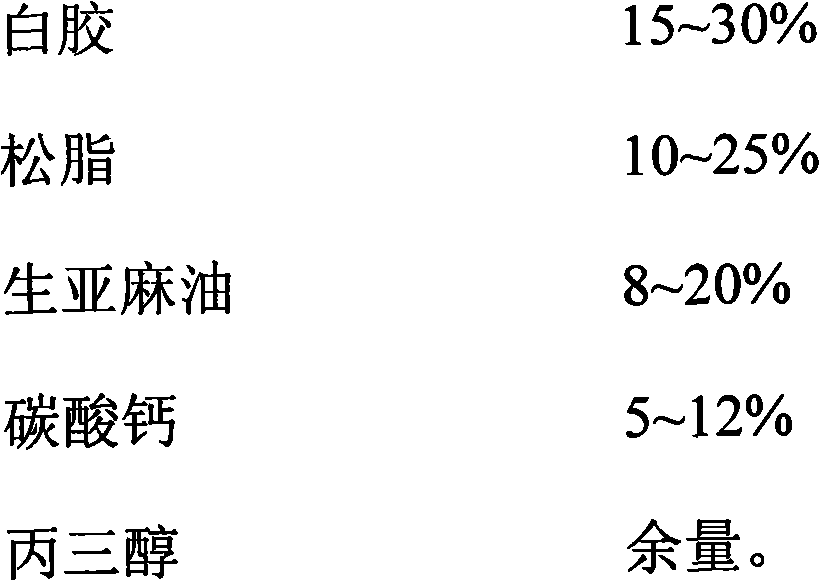

[0012] A molding compound consisting of a mixture of the following ingredients in weight percentages:

[0013]

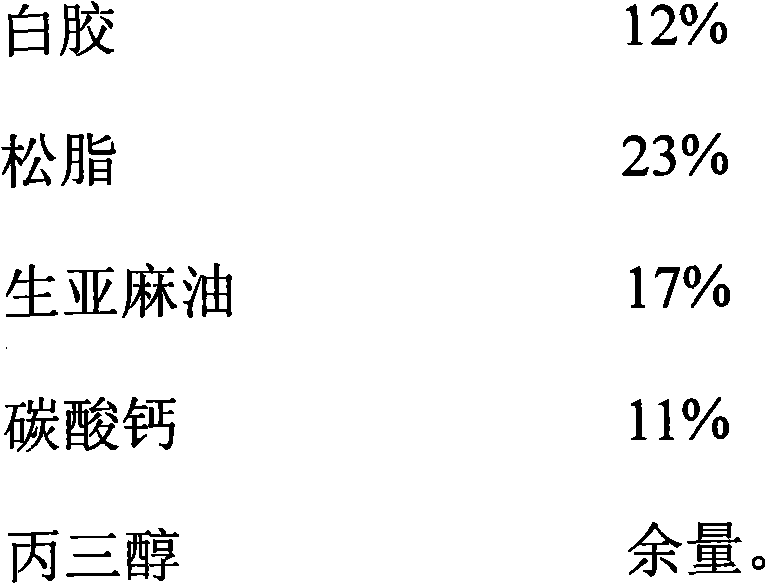

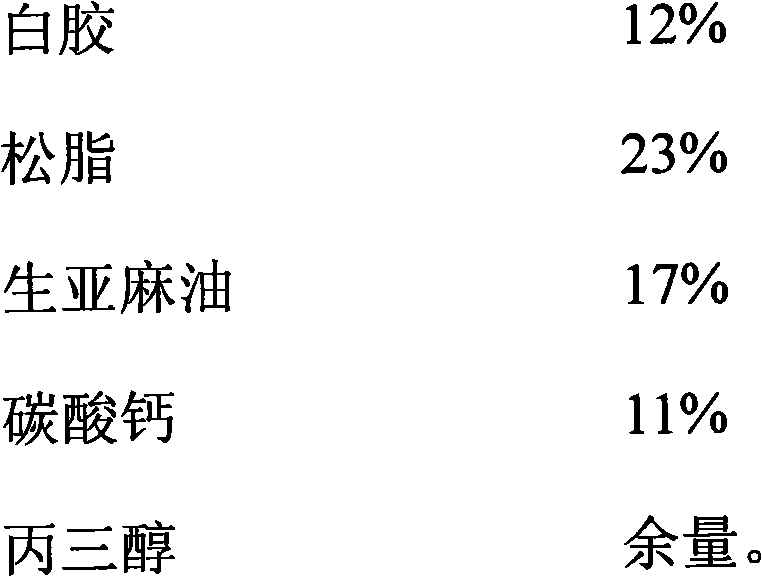

Embodiment 2

[0015] A molding compound consisting of a mixture of the following ingredients in weight percentages:

[0016]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses a die molding gel, which consists of polyvinyl acetate, rosin, raw linseed oil, carbon titanium white and propanetriol. The die molding gel has a reasonable formula and a good using effect, and is low in production cost.

Description

Technical field: [0001] The invention relates to a molding plastic. Background technique: [0002] The existing molding plastics are deficient in aspects such as working effect and production cost. Invention content: [0003] The object of the present invention is to provide a molding plastic with reasonable formula and good application effect. [0004] Technical solution of the present invention is: [0005] A molding plastic is characterized in that it is composed of the following components by weight percentage: [0006] [0007] The molding plastic is composed of the following components by weight percentage: [0008] [0009] The invention has reasonable formula, good use effect and low production cost. [0010] The present invention will be further described below in conjunction with embodiment. detailed description: [0011] Example 1: [0012] A molding compound consisting of a mixture of the following ingredients in weight percentages: [0013] ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C08L93/04C08K5/09C08K5/053C08K3/26

Inventor 范井明

Owner 范井明

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap