Polyether coating defoamer

A defoamer, polyether technology, applied in the direction of coating, etc., can solve the problems of work effect, lack of production cost and so on

Inactive Publication Date: 2011-05-04

李德华

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Existing polyether-type paint defoamers have deficiencies in work effects, production costs, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

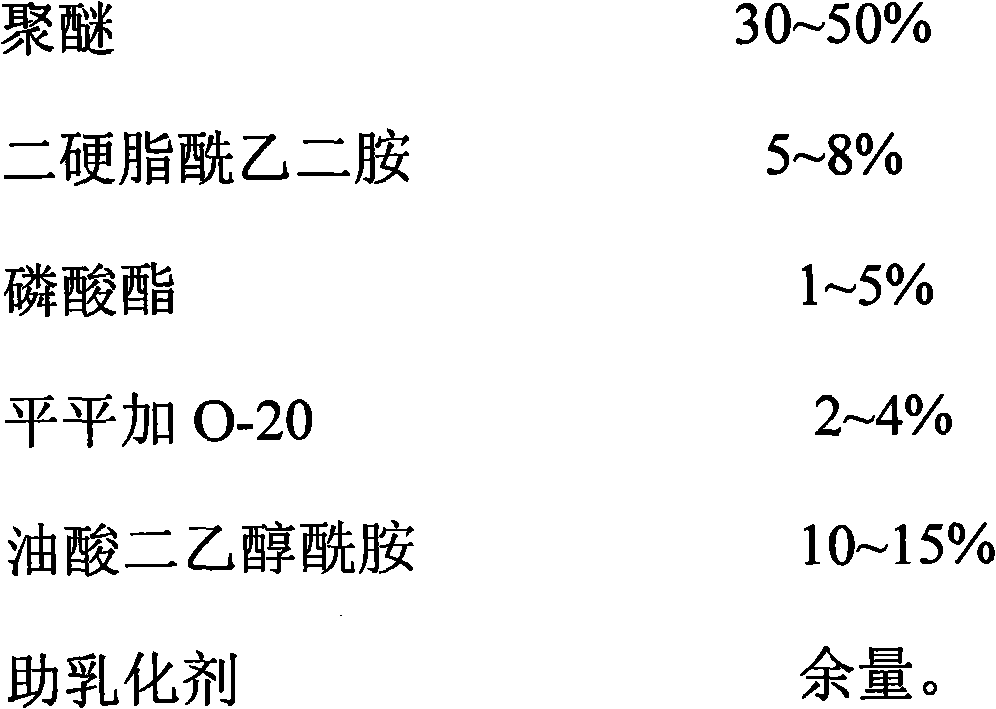

[0013] A polyether type paint defoamer, which is composed of the following components by weight percentage:

[0014]

Embodiment 2

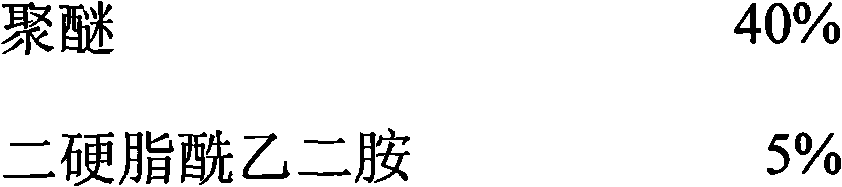

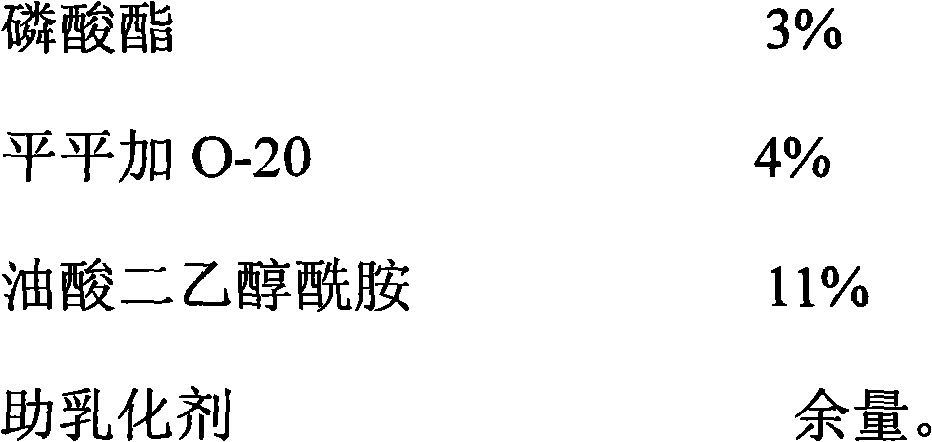

[0016] A polyether type paint defoamer, which is composed of the following components by weight percentage:

[0017]

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a polyether coating defoamer. The defoamer is prepared from polyether, ethylene distearamide, phosphoric acid ester, peregal O-20, oleic diethanolamide and an auxiliary emulsifier. The polyether coating defoamer has the advantages of reasonable formula, good use effect and low production cost.

Description

Technical field: [0001] The invention relates to a polyether type paint defoamer. Background technique: [0002] The existing polyether-type paint defoamer has deficiencies in working effect, production cost and the like. Invention content: [0003] The object of the present invention is to provide a polyether type paint defoamer with reasonable formula and good application effect. [0004] Technical solution of the present invention is: [0005] A kind of polyether type coating defoamer is characterized in that: be made up of the composition mixing of following percentage by weight: [0006] [0007] Described polyether type coating defoamer, is made up of the composition mixing of following percentage by weight: [0008] [0009] [0010] The invention has reasonable formula, good use effect and low production cost. [0011] The present invention will be further described below in conjunction with embodiment. detailed description: [0012] Example 1: [...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D7/12

Inventor 李德华

Owner 李德华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com