Patents

Literature

31 results about "ETHYLENE DISTEARAMIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bitumen modifier

InactiveCN101041744AHigh softening pointImprove anti-aging propertiesBuilding insulationsEpoxyStearic acid

The invention discloses a modifier of pitch for road and water-proofing material, which comprises the following steps: allocating with mass percent as 20-30% polypropylene, 3-10% epoxide resin, 8-10% polyethylene, 8-10% geoceric acid and 40-60% ethylene distearamide; mixing; stirring for 10-15 min; getting the product. This product possesses good stability and predominant water resistance, which can be fit for all of asphalt.

Owner:上海诚鸿道路新材料有限公司

Metal paint

The invention discloses a metal paint. The metal paint comprises following components: modified polybutadiene resin, propylene glycol monomethyl ether acetate, polysiloxane, polyoxyethylene alkylphenol, polydimethylsiloxane and ethylene distearamide; the metal paint comprises the components in percentage by weight: 84.8%-89.7% of the modified polybutadiene resin, 3.4%-4.2% of the propylene glycol monomethyl ether acetate, 1.5%-2.4% of the polysiloxane, 1.7%-2.8% of the polyoxyethylene alkylphenol, 2.6%-3.5% of the polydimethylsiloxane and 1.1%-2.3% of the ethylene distearamide. A modified polybutadiene resin solvent is added with a plurality of additives so that the prepared metal paint has the characteristics of tight texture, low-temperature resistance, flat and smooth formed pattern layer, good adhesiveness and good product quality.

Owner:苏州乾雄金属材料有限公司

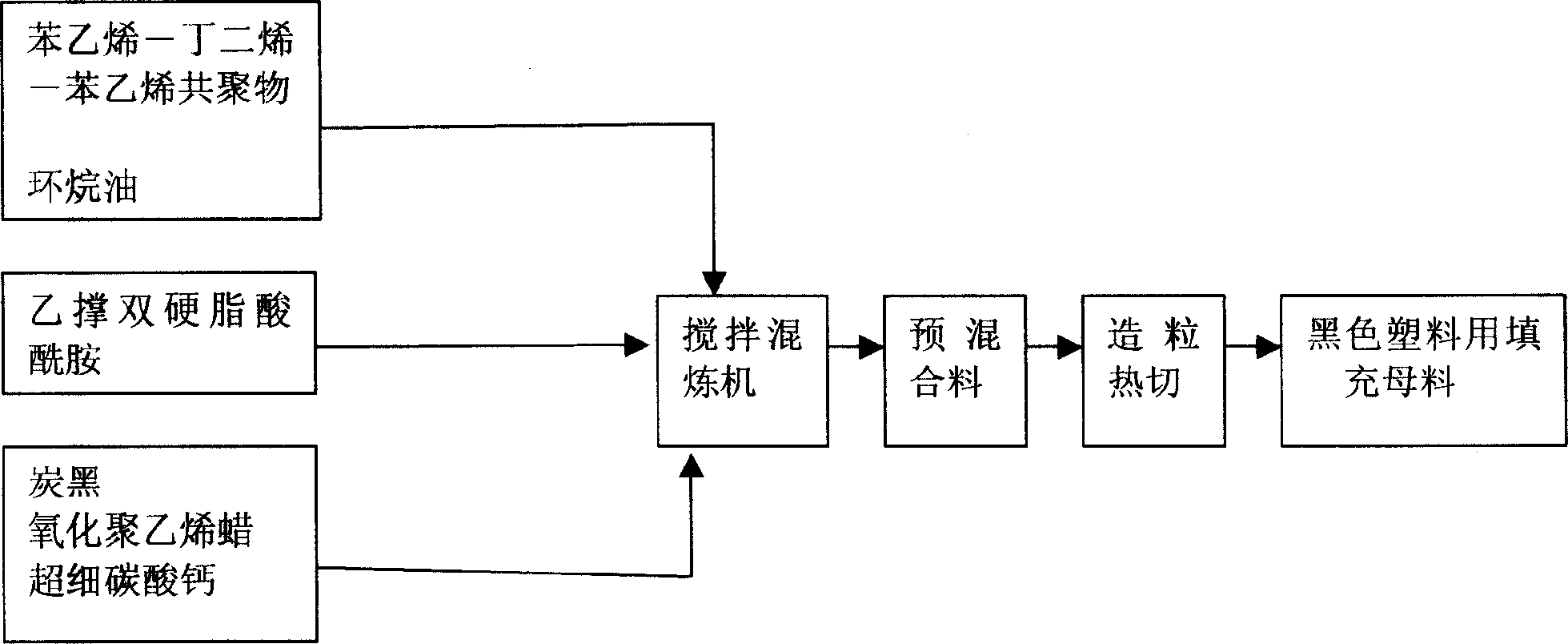

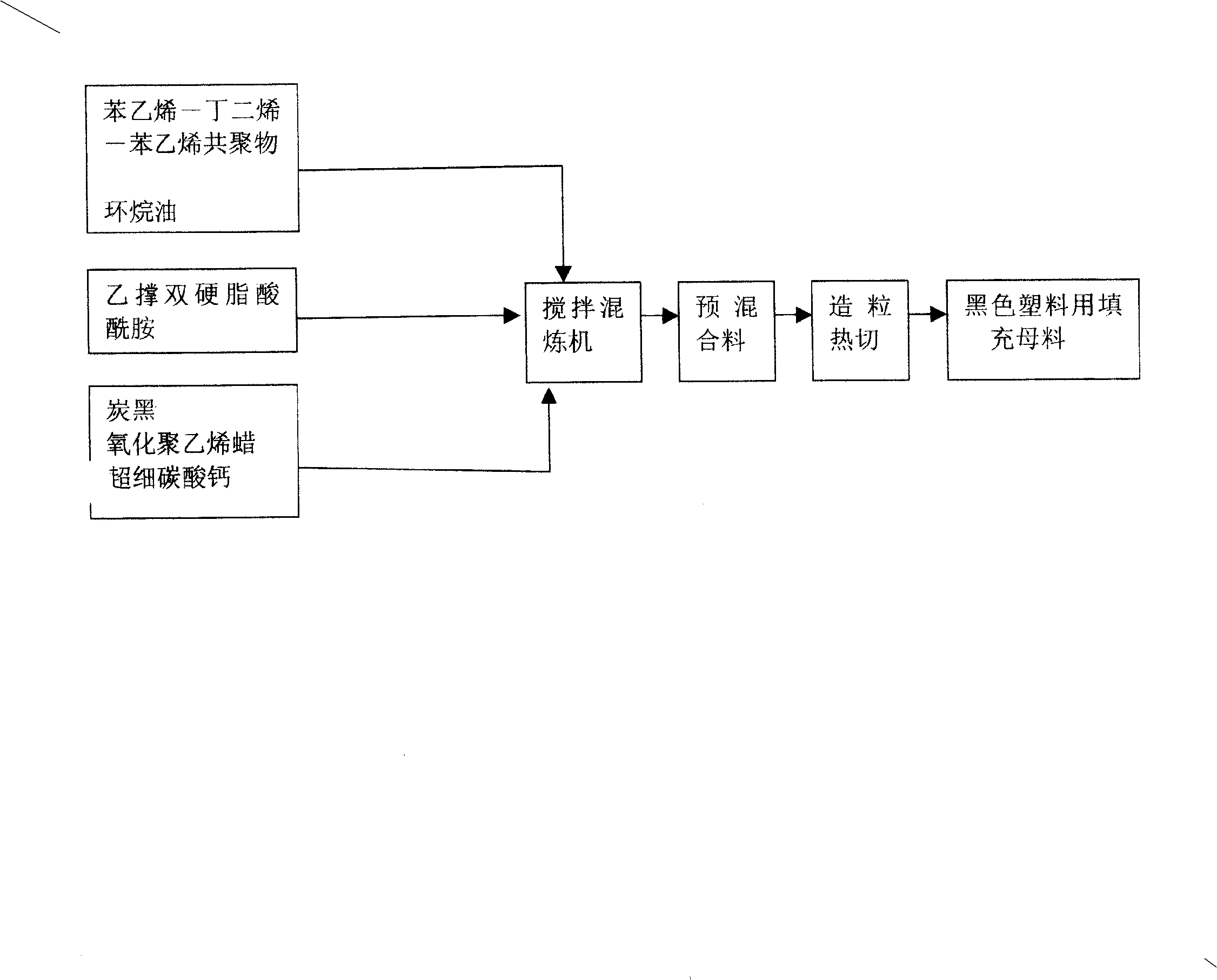

Mother filler of black plastic and its preparing process

The invention discloses a black plastic fill mother material and making method, which comprises the following parts: 25-63% ultrafine carbonate, 10-30% carbon black, 17. 5-25% phenylethene-butadiene-phenylethene copolymer, 1-4% naphthenic oil, 5. 5-15% polyethylene oxide wax and 1-5% ethylene distearamide. The making method comprises the following steps: softening phenylethene-butadiene-phenylethene copolymer and naphthenic oil in the stirrer; placing ultrafine calcium carbonate and carbon black, polyethylene oxide wax in the blender; heating to 120-130 deg. c; adding ethylene distearamide and phenylethene-butadiene-phenylethene copolymer to stir 1-3min; putting preblended material in the double-screw graining machine to grain; cutting; cooling; packing; obtaining the product. The even grain size of ultrafine calcium carbonate is 5-10um and the even grain size of carbon black is 15-40um.

Owner:SHANGHAI LINDA PLASTIC CHEM CO LTD

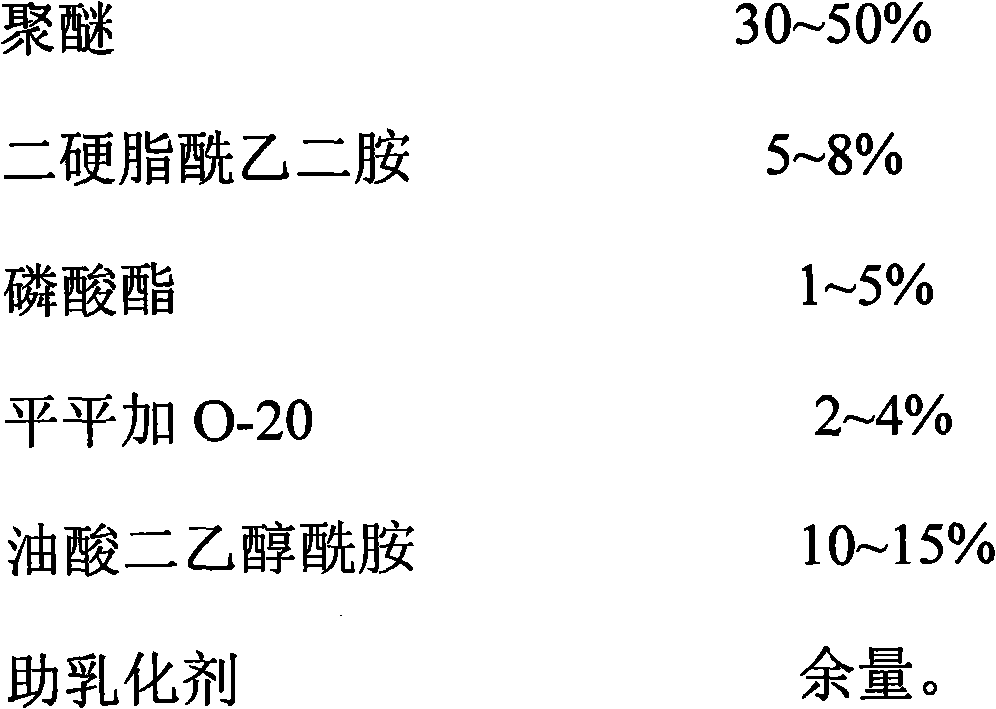

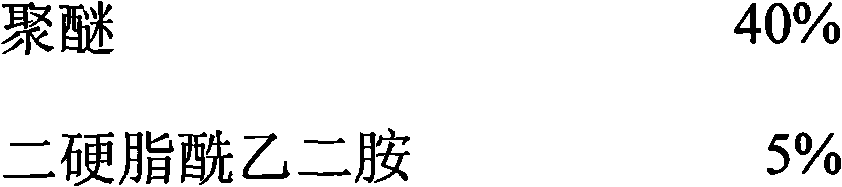

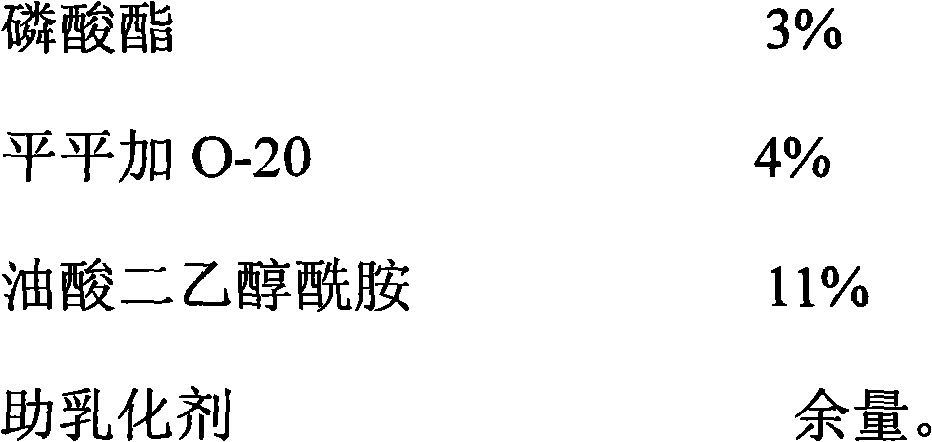

Polyether coating defoamer

The invention discloses a polyether coating defoamer. The defoamer is prepared from polyether, ethylene distearamide, phosphoric acid ester, peregal O-20, oleic diethanolamide and an auxiliary emulsifier. The polyether coating defoamer has the advantages of reasonable formula, good use effect and low production cost.

Owner:李德华

Goods rack

InactiveCN105331235AExcellent anti-rustImprove corrosion resistanceAnti-corrosive paintsFiberGlycidyl methacrylate

The invention discloses a good rack which comprises a metal good rack body. A metal protection coating is attached to the surface of the metal goods rack body. The metal protection coating is prepared from, by weight, 1-2 parts of sodium oleate, 7.6 parts of methyl methacrylate, 1.4 parts of triethylene tetramine, 0.5 part of methylpropanediol, 2.5 parts of calcium sulfate, 0.7 part of fiber brucite, 0.3 part of glycidyl methacrylate and 1.3 parts of ethylene distearamide. According to the goods rack, the metal protection coating is attached to the surface of the metal goods rack body, and the metal goods rack body has good rust preventing, corrosion resisting, oxidization resisting and weather resisting performance.

Owner:常熟市古里镇淼泉大光金属制品厂

Active power filter

InactiveCN104449147AExtended service lifeWith heat insulationAnti-corrosive paintsPolyurea/polyurethane coatingsBrickAcrylic resin

The invention discloses an active power filter. The active power filter comprises a housing which is coated with a protective layer, wherein the protective layer is prepared by the following steps: (1) putting 4.1 parts by weight of acrylic resin, 2.9 parts by weight of sulfited oil, 1.8 parts by weight of ethylene distearamide and 2.4 parts by weight of polyurethane powder into 16.5 parts by weight of deionized water and fully and uniformly stirring to obtain a prime protective coating; (2) putting 2.7 parts by weight of petroleum resin, 1.5 parts by weight of aluminum-carbon-based refractory brick powder, 1.9 parts by weight of triethanolamine and 1.4 parts by weight of zinc-aluminum spinel powder into 13.6 parts by weight of deionized water and fully and uniformly stirring to obtain a top protective coating; (3) firstly spraying the prime protective coating on the surface of the housing, curing and drying; and (4) spraying the top protective coating, curing and drying. According to the active power filter, by coating the housing with protective layers, the service life of the active power filter can be prolonged.

Owner:苏州菲斯特电力科技有限公司

Modified butadiene styrene rubber

The invention discloses modified butadiene styrene rubber. The modified butadiene styrene rubber consists of butadiene styrene rubber, a reinforcing agent, a dispersing agent, a flexibilizer, a tackifier, a coupling agent and a plasticizer, wherein the reinforcing agent is super abrasion furnace black N110; the dispersing agent is ethylene distearamide; the flexibilizer is polyvinyl acetate; the tackifier is hydrogenated rosin resin; the coupling agent is vinyl tri(beta-methoxyethoxy) silane; and the plasticizer is dibutyl phthalate. According to the product, the reinforcing agent, the dispersing agent, the flexibilizer, the tackifier, the coupling agent and the plasticizer are added into the butadiene styrene rubber, so that the obtained modified butadiene styrene rubber has characteristics of high strength, convenience in processing, good elasticity, small shrinkage, good tear resistance, good viscidity and good dispersion.

Owner:TAICANG CHENZHOU PLASTIC

Synthetic leather pulp with functions of environment protection, heat insulation and heat preservation, and preparation method thereof

InactiveCN104389189ASimple recipeImprove insulation effectFibre treatmentDiethylene glycol monobutyl etherThermal insulation

The invention discloses synthetic leather pulp with functions of environment protection, heat insulation and heat preservation, and a preparation method thereof. The synthetic leather pulp comprises the following raw materials in parts by weight: 85-90 parts of polyphenylene thioether, 2-3 parts of metaphenylene diamine, 0.8-1.0 part of ethylene distearamide, 25-30 parts of nanoscale silicon dioxide, 2-3 parts of aluminium-magnesium-silicate, 10-15 parts of peanut leaves, 1.1-1.2 parts of stearic acid, 0.1-0.2 part of calcium ricinoleate, 28-35 parts of light calcium carbonate, 4-4.5 parts of dicumyl peroxide, and 50-55 parts of diethylene glycol monobutyl ether. The pulp disclosed by the invention is simple in a formula, and a paint made from the pulp can effectively realize reflective insulation, and has the advantages of being good in heat preservation effect, stable in heat-insulation property, good in corrosion resistance, long in service life, environment-friendly, and free of pollution. The technical problem that traditional heat-insulation and heat-preservation pulp is nonwaterproof is solved; the peanut leaves are modified, so that the stickiness of the peanut leaves can be improved, the stickiness of the pulp can be enhanced, and the performance stability of the pulp is improved.

Owner:HEFEI ANSHAN COATING FABRICS

Degradable anti-electrostatic packaging material and preparation method thereof

InactiveCN106496978AImprove antistatic performanceGood mechanical propertiesFlexible coversWrappersCarbon nanotubeTributyl citrate

The invention provides a degradable anti-electrostatic packaging material and a preparation method thereof. The preparation method includes: (1) mixing multi-walled carbon nanotubes, yttrium iron garnet and concentrated nitric acid, putting mixture into an ultrasonic apparatus for ultrasonic dispersion, and stirring with a magnetic stirrer; (2) cleaning with distilled water prior to putting into a drying oven for drying to obtain mixed powder; (3) mixing mixed powder, expanded graphite, polylactic acid, polyhydroxyalkanoate, poly butylene succinate, chitin, cinnamon essential oil, ethylene distearamide, epoxidized soybean oil, triacetin and tributyl citrate with a high-speed mixer; (4) adding the mixture into an internal mixer for fusion and internal mixing. The degradable anti-electrostatic packaging material has good anti-electrostatic performance and good degradability, can effectively prevent electrostatic effect, and is excellent in mechanical property and anti-impact property.

Owner:金福英

Plastic material for electronic product shell and processing method thereof

InactiveCN106398147ASolve the problem of serious smell and heavy oily smellImprove wear resistanceCoatingsPlastic materialsGlycerol

The invention discloses a plastic material for an electronic product shell; the plastic material comprises the used raw materials in parts by weight: polylactic acid, polycarbonate, polystyrene, a methyl methacrylate-acrylic acid copolymer, ABS plastics, C15-20 fatty primary amine, a biomass material, bamboo charcoal particles, zinc borate, refined diatomite, ethylene distearamide, lauryl sodium sulfate, glycerol, lubricating grease, a plasticizer, phosphonitrilic chloride, white carbon black, ginger oleoresin, and a pigment. The prepared plastic material effectively solves the problems that a plastic smell is serious and an oil smell is strong after all plastic materials are molded into products at present, can significantly improve the negative ion releasing effect reaching 700-1000 / cm<2>, and has good sterilization and disinfection functions.

Owner:北海威德电子科技有限公司

Corrugated pipe containing sillimanite

The invention discloses a corrugated pipe containing sillimanite. The corrugated pipe is characterized by being prepared from the raw materials in parts by weight: 75-80 parts of PVC (Polyvinyl Chloride) resin, 3-4 parts of polybenzimidazole fiber, 0.6-2 parts of black sand, 0.7-1 part of permethrin, 1-2 parts of boric acid, 2-3 parts of poly (butyl acrylate), 0.3-0.5 part of sodium carboxymethylcellulose, 0.1-0.3 part of butylcellosolve, 2-3 parts of ethylene distearamide, 2-4 parts of vermiculite powder, 1-2 parts of calcium aluminate and 6-10 parts of composite filler. With the adoption of the corrugated pipe, a sample is smooth without a fracture, the two walls of the sample are not disconnected, the inner and outer walls are free of reversed bending, the construction is rapid, the transportation is convenient, and the service life is long when the corrugated pipe is buried in the ground.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

Method for producing fatty acid amide defoaming agent for papermaking

InactiveCN102162202AImprove liquidityEasy to useDefoamers additionPaper/cardboardPapermakingDiethylene glycol

The invention provides a method for producing a fatty acid amide defoaming agent for papermaking. The produced product is a fatty acid amide synthetic defoaming agent and has the characteristics of no toxicity, good fluidity and low price. The defoaming agent is mainly used for alkaline pulping and papermaking processes in the papermaking industry. The use conditions in recent years show that the fatty acid amide defoaming agent has good defoaming and foam inhibiting effects, is simple and convenient to operate and has high pulp yield and quality in the alkaline pulping and papermaking processes. The following raw materials are used for producing the product: ethylene distearamide, diethylene glycol mono-oleate, mineral oil, silica, sodium carbonate, oxidized polyethylene and calcium stearate.

Owner:殷邗清

Wood shredding device

InactiveCN104530920ALong runImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyTectorial membrane

The invention discloses a wood shredding device which comprises a box body, wherein a knife roll is arranged in the box body; multiple blades are arranged on the knife roll; the knife roll is provided with a driving device; the surface of the blades coats with a protective film; and the protective film consists of the following components in parts by weight: 5.5 parts of epoxy resin E-12, 0.7 part of ethylene distearamide, 1.1 parts of methyl propanediol, 0.9 part of 12-hydroxystearic acid, 1.1 parts of rubellan ferric oxide and 0.6 part of triethanolamine. According to the wood shredding device disclosed by the invention, the blades are coated with the protective film, so that the blades have excellent wear resistance and corrosion resistance, and the wood shredding device can operate for a long time.

Owner:常熟市首誉机械有限公司

Antibacterial polystyrene material and preparation method thereof

InactiveCN104672648AImprove high temperature resistanceImprove the bactericidal effectCellulosePolymer science

The invention discloses an antibacterial polystyrene material and a preparation method thereof. The antibacterial polystyrene material is prepared form the following components in parts by weight: 78-84 parts of polystyrene, 12-15 parts of carboxymethylcellulose, 6-8 parts of ethylene distearamide, 5-8 parts of maleic anhydride grafted polypropylene, 5-7 parts of polyethylene glycol, 4-6 parts of propylene glycol monomethyl ether and 0.5-1 part of parachlormetaxylenol. The invention further provides a preparation method of the antibacterial polystyrene material. The preparation method comprises the following steps: adding all the components into a high-pressure homogenizer and mixing uniformly; carrying out ultrasonic treatment on the uniformly mixed material for 5-10min, adding into a feeding opening of a twin-screw extruder for melt extrusion and pelleting, thus obtaining the antibacterial polystyrene material.

Owner:SUZHOU KANGHUA PURIFYING SYST ENG

Tail-gas detection device

InactiveCN105348978AImprove cold resistanceGood weather resistanceAnti-corrosive paintsElectrically-conductive paintsFiberHexyldecanol

The invention disclose a tail-gas detection device. The tail-gas detection device comprises a metal shell, a detection module is arranged in the metal shell and comprises a reagent storage cavity used for storing a reagent, a protective film adheres to the outer surface of the reagent storage cavity, and the protective film is prepared from, by weight, 1-2 parts of lignosulfonate, 1.4 parts of ethylene distearamide, 0.7 part of fiber brucite, 0.9 part of organic bentonite, 0.3 part of aluminum residue fine powder, 0.7 part of mica powder, 1.4 parts of ferricyanate, 1.7 parts of barium petroleum sulfonate, 0.7 part of hexyldecanol and 12.6 parts of petroleum resin. According to the tail-gas detection device, the protective film adheres to the outer surface of the reagent storage cavity which has good corrosion resistant, antioxidant, anti-static, heat resistant, cold resistant and weather resistant performance, it is guaranteed that the reagent is not affected by the external, and the detection stability is guaranteed.

Owner:JIANGSU GUOTAI ENVIRONMENTAL MONITORING CO CHANGSHU BRANCH

Composite material with wide damping temperature range

InactiveCN104448445AExcellent low-frequency noise reduction performanceWide damping temperature rangeStearic acidPolybutylene terephthalate

The invention discloses a composite material with a wide damping temperature range. The composite material with the wide damping temperature range is prepared from the following substances in parts by weight: 55 to 62 parts of emulsion polymerized butadiene styrene rubber, 17 to 29 parts of polytetrafluoroethylene, 9 to 14 parts of isoprene rubber, 3 to 9 parts of hard ethylene distearamide, 13 to 20 parts of glyceryl monostearate, 3 to 6 parts of dimethyl siloxane, 11 to 16 parts of glass fiber, 9 to 12 parts of polybutylene terephthalate, 5 to 17 parts of chlorcosane, 3 to 5 parts of N-phenyl-beta-naphthylamine, and 5.5 to 9.5 parts of aluminum acetylacetonate. The composite material with the wide damping temperature range has the characteristics of outstanding low-frequency noise reduction performance, light weight, wide damping temperature range, wide noise reduction bandwidth, ageing resistance and the like.

Owner:QINGDAO LUYUANJIA IND & TRADE

Defoaming agent for coating and process for preparing same

ActiveCN105778610AThe preparation process steps are simpleEasy to operateCoatingsKeroseneAmmonium hydroxide

The invention discloses a defoaming agent for coating. The deforming agent for coating is prepared from the following components in parts by weight: 14 to 20 parts of ethydene bis-palmitamide, 5 to 12 parts of ethylene distearamide, 9 to 20 parts of tetramethyl ammonium hydroxide, 3 to 8 parts of fatty alcohol-polyoxyethylene ether, 33 to 39 parts of kerosene, 10 to 18 parts of white oil, 6 to 14 parts of aluminum dibutyrate, 3 to 8 parts of aluminum linolenate and 6 to 12 parts of aluminum dilinoleate. The defoaming agent provided by the invention can obviously reduce small bubbles produced when wall surfaces is coated with the coating, guarantee the integrity of the wall surfaces coated with the coating and simultaneously improve the attractiveness. The invention further discloses a process for preparing the defoaming agent for coating. The process comprises the following steps: uniformly mixing all the components, then putting the mixture in a reaction kettle, and preserving heat for 10h at temperature of 180 DEG C to obtain a product A; grinding the product A to obtain the defoaming agent for coating. The process for preparing the defoaming agent for coating provided by the invention is simple in steps, easy to operate and low in preparation cost.

Owner:NANTONG HANTAI CHEM

Glass protective film

The invention discloses a glass protective film which is prepared from, by weight, 7.9 parts of butyl rubber, 1-2 parts of dibutyl phthalate, 0.2 part of acrylic acid, 1.3 parts of light calcium carbonate, 2.4 parts of ethylene distearamide, 1.2 parts of fatty alcohol-polyoxyethylene ether, 1.3 parts of methyltrimethoxysilane and 2.3 parts of 1,4-cyclohexynol. The glass protective film can improve the heat-isolation, heat-preservation, cold-resistant, anti-explosion, anti-corrosion, anti-bacterial and anti-static performance of glass.

Owner:CHANGSHU SEDY INLAY GLASS PROD

Anti-flaming zipper

InactiveCN105266283AExcellent flame retardantImprove corrosion resistanceFireproof paintsSlide fastenersFiberEngineering

The invention discloses an anti-flaming zipper. The anti-flaming zipper comprises a zipper belt, wherein the longitudinal edge of the zipper belt is provided with zipper teeth; the zipper belt is made of fire resistant fibers; the zipper teeth are made of metal and coated with a zipper tooth protection layer; the zipper tooth protection layer is prepared from, by weight, 1-2 parts of sodium hyroxyethyl sulfonate, 7.7 parts of alkyd resin, 2.1 parts of ethylene distearamide, 0.8 part of epoxy acid zinc, 1.6 parts of allyl heptanoate, 0.9 part of aluminium phosphate, 1.3 parts of propylene glycol and 2.7 parts of activated methyl polyester resin. The anti-flaming zipper has excellent anti-flaming, anti-corrosion, rust-proof and anti-oxidation properties.

Owner:江苏汇源拉链制造有限公司

Preparation method and application of thermosetting powder coating

InactiveCN108610900AImprove fire performanceImprove performanceFireproof paintsPowdery paintsEpoxyPolymer science

The invention discloses a preparation method and application of a thermosetting powder coating. The method adopts water-borne acrylic epoxy resin, polylactic acid resin, hydrogenated rosin pentaerythritol ester, N,N-methylene bisacrylamide and ethylene distearamide for reaction at high temperature to prepare a high temperature reactant, kaolin is soaked in acid, calcined and modified into a modified calcined reactant, the high temperature reactant and the modified calcined reactant are mixed, and then asbestos powder, allyl thiourea, a pigment, a leveling agent and a film forming agent are added for ultrasonic dispersion; and then a molten extrusion material is obtained by heating, melting, mixing and extrusion and is pressed into flakes; and finally, the flake material is crushed, cyclone-separated, graded and screened, detected and packed to obtain the finished product. The prepared thermosetting powder coating has good fireproof performance and good application prospect in buildingcoating.

Owner:SUZHOU JUKANG NEW MATERIAL TECH

Surface treating agent for chrome-based aluminum alloy

InactiveCN104099599AImprove corrosion resistanceGood chemical resistanceMetallic material coating processesChromium trioxideIsobutanol

The invention discloses a surface treating agent for a chrome-based aluminum alloy. The surface treating agent comprises the following raw materials in parts by weight: 0.5-1 part of tea saponin, 0.7-2 parts of ethylene distearamide, 1-2 parts of sodium carboxymethylcellulose, 2.5-4 parts of polylactic acid, 1-2 parts of sodium gluconate, 0.1-0.2 part of chromium trioxide, 0.2-0.4 part of potassium chloride, 0.1-0.4 part of 8-hydroxyquinoline, 0.2-0.4 part of dimethylamino propylamine, 5.6-8 parts of isobutanol, 1-2 parts of coalescing agent, 16-20 parts of silane coupling agent KH570, and 100-140 parts of de-ionized water. The surface treating agent has excellent corrosion resistance, chemicals resistance, heat discoloration resistance and weather resistance, is effective for aluminum alloy workpieces without scratches, and can achieve excellent corrosion resisting effect on exposed scratched parts.

Owner:六安华邦机电有限公司

Mother filler of black plastic and its preparing process

The invention discloses a black plastic fill mother material and making method, which comprises the following parts: 25-63% ultrafine carbonate, 10-30% carbon black, 17. 5-25% phenylethene-butadiene-phenylethene copolymer, 1-4% naphthenic oil, 5. 5-15% polyethylene oxide wax and 1-5% ethylene distearamide. The making method comprises the following steps: softening phenylethene-butadiene-phenylethene copolymer and naphthenic oil in the stirrer; placing ultrafine calcium carbonate and carbon black, polyethylene oxide wax in the blender; heating to 120-130 deg. c; adding ethylene distearamide and phenylethene-butadiene-phenylethene copolymer to stir 1-3min; putting preblended material in the double-screw graining machine to grain; cutting; cooling; packing; obtaining the product. The even grain size of ultrafine calcium carbonate is 5-10um and the even grain size of carbon black is 15-40um.

Owner:SHANGHAI LINDA PLASTIC CHEM CO LTD

Modified expandable polystyrene rubber

The invention discloses modified expandable polystyrene rubber. The modified expandable polystyrene rubber is prepared from expandable polystyrene plastic, fire retardant, flexibilizer, filler, anti-impact modifier and dispersant, the fire retardant is boric acid, the flexibilizer is liquid silicon rubber, the filler is talcum powder, the anti-impact modifier is chlorinated polyethylene, and the dispersant is ethylene distearamide. The modified expandable polystyrene rubber is prepared from, by weight, 70-75 parts of expandable polystyrene plastic, 6-10 parts of boric acid, 18-22 parts of liquid silicon rubber, 29-33 parts of talcum powder, 14-18 parts of chlorinated polyethylene and 9-13 parts of ethylene distearamide. The modified expandable polystyrene rubber has the advantages of being high in fire retardance and strength, high in impact strength and hardness, low in cost and good in quality.

Owner:苏州市云林电子有限公司

Anti-fouling inner wall coating easy to clean and preparation method thereof

InactiveCN107099208AGood antifoulingNot easy to stickAntifouling/underwater paintsPaints with biocidesDibenzoyl PeroxidePOLYOXYETHYLENE ETHER

The invention discloses anti-fouling inner wall coating easy to clean and a preparation method thereof. The anti-fouling inner wall coating comprises, by weight, 95-100 parts of acrylic emulsion, 35-40 parts of polyoxyethylene, 28-32 parts of epoxy acrylate, 23-27 parts of wollastonite powder, 30-35 parts of anatase titanium dioxide, 20-25 parts of talcum powder, 2-5 parts of methyl phenylglyoxylate, 3-6 parts of ethylene distearamide, 5-9 parts of dibenzoyl peroxide, 10-15 parts of nano calcium carbonate, 8-12 parts of zinc naphthenate, 1-3 parts of polyoxyethylene polyoxypropylene ether, 7-10 parts of succinimide and 3-6 parts of dimethylethanolamine. The prepared inner wall coating is good in anti-fouling performance, easy to clean an capable of greatly lowering the difficulty for keeping indoor cleanliness.

Owner:FOSHAN LINGXIN INFORMATION TECH CO LTD

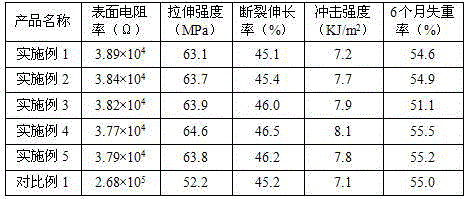

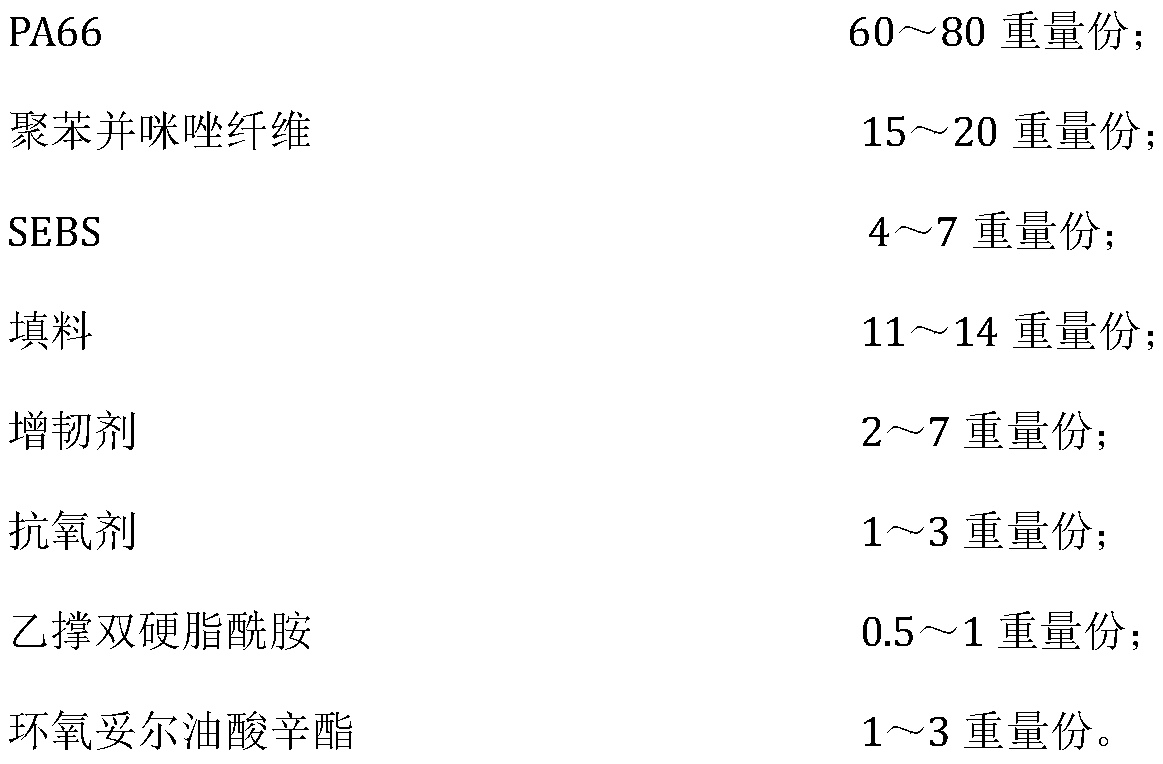

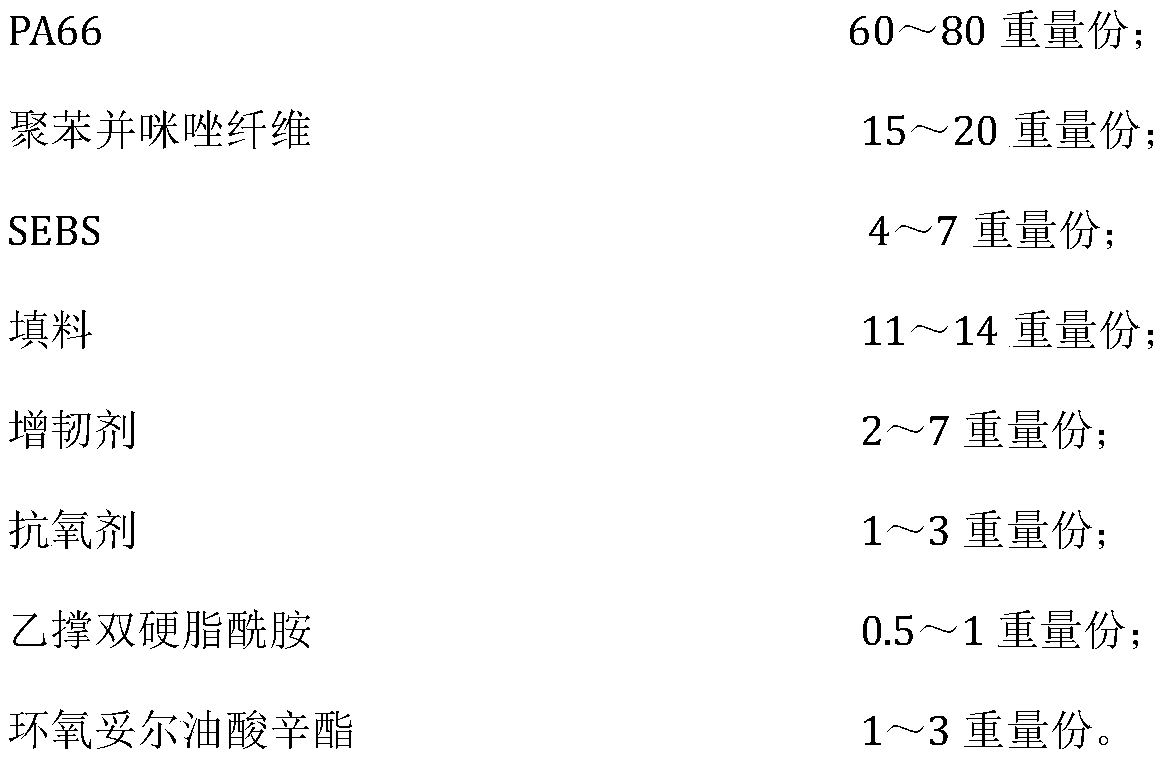

High heat resistant and toughened heat conduction PA66 material and preparation method thereof

The invention discloses a high heat resistant and toughed heat conduction PA66 material. The high heat resistant and toughened heat conduction PA66 material comprises, by weight, 60-80 parts of PA66,15-20 parts of polybenzimidazole fiber, 4-7 parts of SEBS, 11-14 parts of a filler, 2-7 parts of a flexiblizer, 1-3 parts of an antioxygen, 0.5-1 part of ethylene distearamide and 1-3 parts of epoxy tol oleate octyl ester. The high heat resistant and toughened heat conduction PA66 material has excellent mechanical properties, heat resistance and heat conduction through optimization of chemical composition of the material and improvement of the internal structure of PBT (polybutylene terephthalate) plastic to microscope extent.

Owner:NANTONG KEPOLY ENG PLASTICS CO LTD

Gaseous phase scale inhibitor for multiple types of gas booster fans

Disclosed is a gaseous phase scale inhibitor for multiple types of gas booster fans. The gaseous phase scale inhibitor comprises the following components of, by mass, 30%-45% of polyaspartic acid, 5%-10% of diethylenetriamine, 5%-10% of ethylene distearamide, 30%-45% of hexamethylenediamine tetramethylene phosphonic acid and 1% -10% of petroleum ether. The scale inhibitor is added into a blast furnace gas pipeline in front of an inlet of a compressing blower through a metering pump and atomized fast by means of residual temperature of blast furnace gas and kinetic energy of the gas. The atomized scale inhibitor enters a fan cavity channel and makes complete contact with the surface of a fan rotor along with the gas, and the purposes of protection and scale inhibition for the fan rotor and blades in the gaseous (atomized) state are achieved. The gaseous phase scale inhibitor for the multiple types of gas booster fans is suitable for scale inhibition for blast furnace gas, coke oven gas, converter gas and other multiple types of gas booster fans.

Owner:SHAANXI YUTENG IND

Method for manufacturing nickel-ion-chromium alloy seamless tube

InactiveCN105273562AImprove corrosion resistanceExcellent anti-rustAnti-corrosive paintsPolycarbonate coatingsWeather resistancePentaerythritol

The invention discloses a method for manufacturing a nickel-ion-chromium alloy seamless tube. The method comprises the step of attaching a metal tube main body to a metal protective coating. The metal protective coating comprises the following components in parts by weight: 1-2 parts of pentaerythritol, 8.7 parts of a modified polybutadiene resin, 2.3 parts of ethylene distearamide, 0.9 part of dibromomethane, 0.8 part of titanium dioxide, 0.4 part of silicon dioxide and 1.8 parts of polycarbonate. According to the method for manufacturing the nickel-ion-chromium alloy seamless tube disclosed by the invention, the metal protective coating is attached to the metal tube main body, and the metal tube main body has excellent corrosion resistance, rust resistance and weather resistance.

Owner:SUZHOU BEST METAL PROD

Flame-retardant PE (polyethylene) pipe easy to color

The invention provides a flame-retardant PE (polyethylene) pipe easy to color. The PE pipe comprises a first plastic pipe located outside and a second plastic pipe located inside; the first plastic pipe comprises PE, a filling agent, a flame retardant, a coloring agent, an anti-static agent and a dispersant; the filling agent is diatomite, the flame retardant is a bromine flame retardant, the coloring agent is titanium dioxide, the anti-static agent is sodium dodecyl benzene sulfonate, and the dispersant is ethylene distearamide; the second plastic pipe comprises PE, a flame retardant, a coloring agent, a coupling agent and a reinforcing agent; the flame retardant is antimony pentoxide, the coloring agent is zinc oxide powder, the coupling agent is vinyltriethoxysilane, and the reinforcingagent is carbon black.

Owner:江苏远通塑胶制品有限公司

Concentric pipe-following drilling tool

The invention discloses a concentric pipe-following drilling tool. The concentric pipe-following drilling tool comprises a drilling tool body. The drilling tool body is coated with a protective layer. A preparing method of the protective layer includes the following steps that 1, 5.7 parts of modified polybutadiene resin, 2.3 parts of ethylene distearamide. 0.5 part of titanium dioxide, 1.1 parts of aluminum oxide, 1.3 parts of phenylcarbinol, 1.3 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride are taken and sufficiently stirred to be even, and a bottom-layer protective coating is obtained; 2, 6.7 parts of polyamino resin, 1.6 parts of methyl methacrylate, 1.2 parts of vinyl trimethoxy silane, 0.9 part of castor oil, 0.4 part of silicon dioxide and 1.2 parts of lime powder are taken and sufficiently stirred to be even, and a face-layer protective coating is obtained; 3, the bottom-layer protective coating is sprayed to the surface of the drilling tool body, cured and dried; 4, then the face-layer protective coating is sprayed, cured and dried. According to the concentric pipe-following drilling tool, the drilling tool body is coated with the protective layer, and the service life of the concentric pipe-following drilling tool can be prolonged.

Owner:常熟市地大探矿机械厂

Defoamer for paint and its preparation process

The invention discloses a defoaming agent for coating. The deforming agent for coating is prepared from the following components in parts by weight: 14 to 20 parts of ethydene bis-palmitamide, 5 to 12 parts of ethylene distearamide, 9 to 20 parts of tetramethyl ammonium hydroxide, 3 to 8 parts of fatty alcohol-polyoxyethylene ether, 33 to 39 parts of kerosene, 10 to 18 parts of white oil, 6 to 14 parts of aluminum dibutyrate, 3 to 8 parts of aluminum linolenate and 6 to 12 parts of aluminum dilinoleate. The defoaming agent provided by the invention can obviously reduce small bubbles produced when wall surfaces is coated with the coating, guarantee the integrity of the wall surfaces coated with the coating and simultaneously improve the attractiveness. The invention further discloses a process for preparing the defoaming agent for coating. The process comprises the following steps: uniformly mixing all the components, then putting the mixture in a reaction kettle, and preserving heat for 10h at temperature of 180 DEG C to obtain a product A; grinding the product A to obtain the defoaming agent for coating. The process for preparing the defoaming agent for coating provided by the invention is simple in steps, easy to operate and low in preparation cost.

Owner:NANTONG HANTAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com