Mother filler of black plastic and its preparing process

A technology for filling master batches and plastics, which is applied in the field of filling master batches for black plastics and their preparation, can solve the problems of reducing the manufacturing cost of black plastics, increasing the cost of products, and degrading performance, and achieves improved processing fluidity, less machine wear, The effect of reducing viscosity

Active Publication Date: 2007-07-11

SHANGHAI LINDA PLASTIC CHEM CO LTD

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is to solve the problem that both the filler masterbatch and the black masterbatch must be added when the traditional filler masterbatch is used to process black plastics, resulting in increased product cost, decreased performance, and the problem that it cannot be applied to the field of engineering plastics. A filler masterbatch for black plastic, which eliminates the need to add black masterbatch and traditional filler masterbatch when processing black plastic, and can be used in the field of engineering plastics to reduce the manufacturing cost of black plastic

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] Embodiment 1: formula ratio is as follows:

[0028]

Embodiment 2

[0029] Embodiment 2: formula ratio is as follows:

[0030]

Embodiment 3

[0031] Embodiment 3: formula ratio is as follows:

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

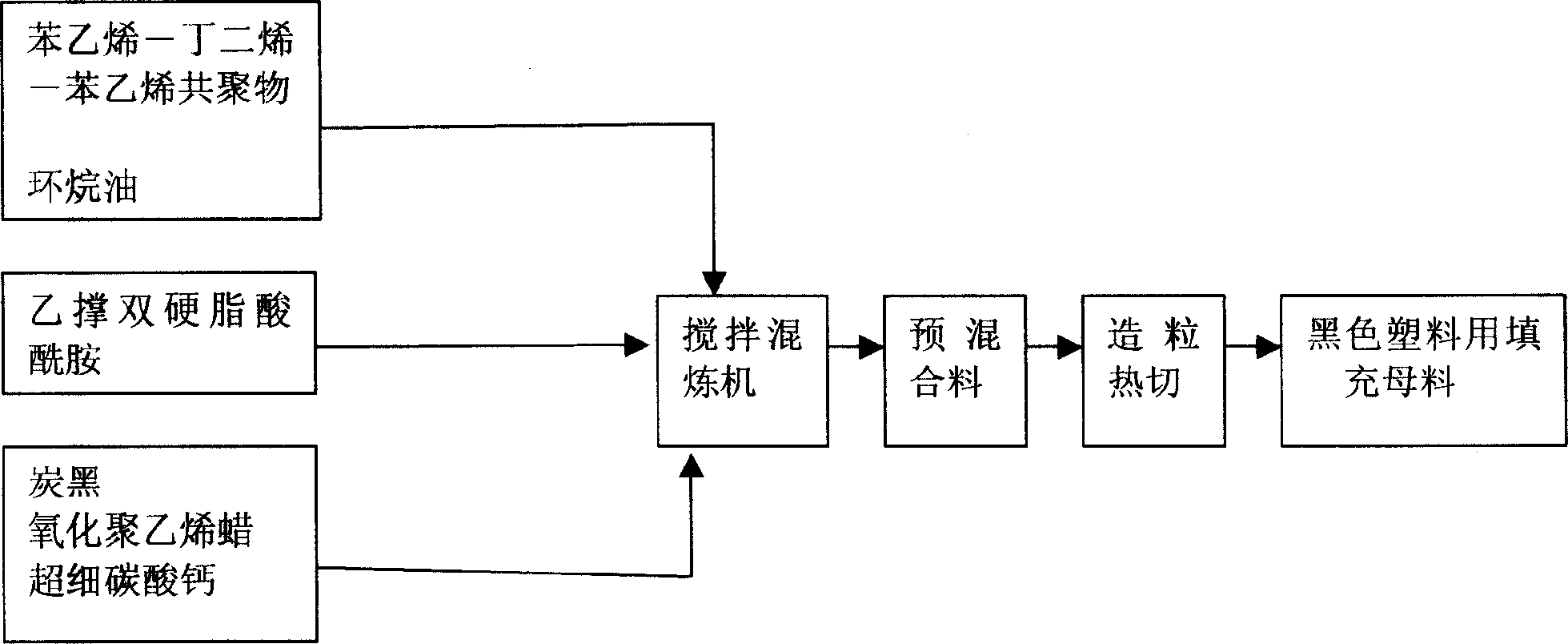

The invention discloses a black plastic fill mother material and making method, which comprises the following parts: 25-63% ultrafine carbonate, 10-30% carbon black, 17. 5-25% phenylethene-butadiene-phenylethene copolymer, 1-4% naphthenic oil, 5. 5-15% polyethylene oxide wax and 1-5% ethylene distearamide. The making method comprises the following steps: softening phenylethene-butadiene-phenylethene copolymer and naphthenic oil in the stirrer; placing ultrafine calcium carbonate and carbon black, polyethylene oxide wax in the blender; heating to 120-130 deg. c; adding ethylene distearamide and phenylethene-butadiene-phenylethene copolymer to stir 1-3min; putting preblended material in the double-screw graining machine to grain; cutting; cooling; packing; obtaining the product. The even grain size of ultrafine calcium carbonate is 5-10um and the even grain size of carbon black is 15-40um.

Description

1. Technical field: [0001] The invention relates to a masterbatch and a preparation method thereof, in particular to a filling masterbatch for black plastics and a preparation method thereof. 2. Background technology: [0002] Usually, in the process of plastic processing, the added additives and fillers are concentrated in the carrier resin to make a filler masterbatch, which has the following advantages: easy to measure and blend, clean the working environment, etc. [0003] The main purpose of adding polyolefin filler masterbatch with calcium carbonate as a filler in plastic products is to ensure the good processing performance of the material and at the same time to add the largest amount, and to replace high-cost polyolefin raw materials with cheap filler masterbatch , in order to achieve the purpose of reducing production cost and improving performance. [0004] The choice of carrier resin for plastic filler masterbatch in my country mainly includes random polypropyle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L25/08C08K5/20B29B9/12C08L23/06C08K3/04C08K3/26

Inventor 王梓刚

Owner SHANGHAI LINDA PLASTIC CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com