Degradable anti-electrostatic packaging material and preparation method thereof

A packaging material and anti-static technology, which is applied in the field of degradable anti-static packaging materials and its preparation, can solve problems such as environmental damage, and achieve the effects of preventing electrostatic effects, good degradability, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

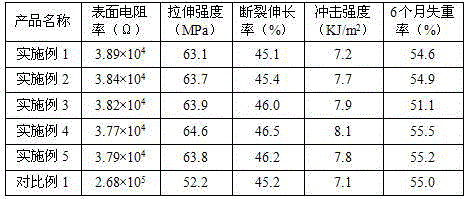

Examples

Embodiment 1

[0016] A degradable antistatic packaging material prepared from the following components in parts by weight: 1 part of multi-walled carbon nanotubes, 1 part of expanded graphite, 0.5 parts of yttrium iron garnet, 40 parts of polylactic acid, and 20 parts of polyhydroxyalkanoate 30 parts of polybutylene succinate, 2 parts of chitin, 1 part of cinnamon essential oil, 1 part of ethylene bis stearamide, 1 part of epoxy soybean oil, 3 parts of glyceryl triacetate, tributyl citrate 2 parts of ester, 20 parts of concentrated nitric acid, 60 parts of concentrated sulfuric acid.

[0017] The preparation method of the above-mentioned degradable anti-static packaging material is as follows: (1) Mix multi-walled carbon nanotubes, yttrium iron garnet, concentrated nitric acid and concentrated sulfuric acid, put them into an ultrasonic instrument for ultrasonic dispersion for 30 minutes, and use a magnetic stirrer at a speed of Stir at 150r / min and 140°C for 4 hours; (2) wash with distilled...

Embodiment 2

[0019] A degradable anti-static packaging material prepared from the following components in parts by weight: 1.5 parts of multi-walled carbon nanotubes, 1.2 parts of expanded graphite, 0.6 parts of yttrium iron garnet, 45 parts of polylactic acid, and 25 parts of polyhydroxyalkanoate 35 parts of polybutylene succinate, 2.5 parts of chitin, 1.5 parts of cinnamon essential oil, 1.2 parts of ethylene bis stearamide, 1.5 parts of epoxy soybean oil, 4 parts of triacetin, tributyl citrate 3-4 parts of ester, 25 parts of concentrated nitric acid, 65 parts of concentrated sulfuric acid.

[0020] The preparation method of the above-mentioned degradable anti-static packaging material is as follows: (1) Mix multi-walled carbon nanotubes, yttrium iron garnet, concentrated nitric acid and concentrated sulfuric acid, put them into an ultrasonic instrument for ultrasonic dispersion for 35 minutes, and use a magnetic stirrer at a speed of Stirring at 170r / min and 142°C for 4.5 hours; (2) Was...

Embodiment 3

[0022] A degradable antistatic packaging material prepared from the following components in parts by weight: 2 parts of multi-walled carbon nanotubes, 1.5 parts of expanded graphite, 0.75 parts of yttrium iron garnet, 50 parts of polylactic acid, and 30 parts of polyhydroxyalkanoate 40 parts of polybutylene succinate, 3 parts of chitin, 2 parts of cinnamon essential oil, 1.5 parts of ethylene bis stearamide, 2 parts of epoxidized soybean oil, 5 parts of glyceryl triacetate, tributyl citrate 3.5 parts of ester, 30 parts of concentrated nitric acid, 70 parts of concentrated sulfuric acid.

[0023] The preparation method of the above-mentioned degradable anti-static packaging material is as follows: (1) Mix multi-walled carbon nanotubes, yttrium iron garnet, concentrated nitric acid and concentrated sulfuric acid, put them into an ultrasonic instrument for ultrasonic dispersion for 35 minutes, and use a magnetic stirrer at a speed of Stirring at 175r / min and 142°C for 4.5 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com