High heat resistant and toughened heat conduction PA66 material and preparation method thereof

A PA66 and toughening technology, which is applied in the field of high heat resistance and toughening thermal conductivity PA66 material and its preparation, can solve the problem of heat dissipation of thermal interface materials, difficulty in meeting the requirements for thermal conductivity, and heat resistance. Insufficient and other problems, to achieve the effect of preventing decomposition and aging, excellent mechanical properties, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of a high heat-resistant toughened type thermally conductive PA66 material, wherein the preparation method comprises the following steps:

[0034] 1) PA66, SEBS, ethylene bis stearamide, octyl epoxy tall oleate, titanium boride, tantalum carbide, polyvinyl acetate, polyvinyl butyral, zinc ethyl phenyl dithiocarbamate , N, N-bis(2,4-diiminodiphenyl ether) imine, di-n-octyltin maleate, di-n-octyltin maleate, tetrafluoroethylene-perfluoro(vinyl polyalkoxy sulfonic acid base) ether copolymer and isopropyl titanate triisostearate were stirred and mixed to obtain the first mixture; 2) the first mixture was added from the main feeding port of the twin-screw extruder, and the polybenzimidazole fiber was made of glass fiber Add it through the mouth, control the rotation speed at 800-1200r / min, and the temperature at 265-285°C, and carry out extrusion granulation to obtain PA66.

Embodiment 1

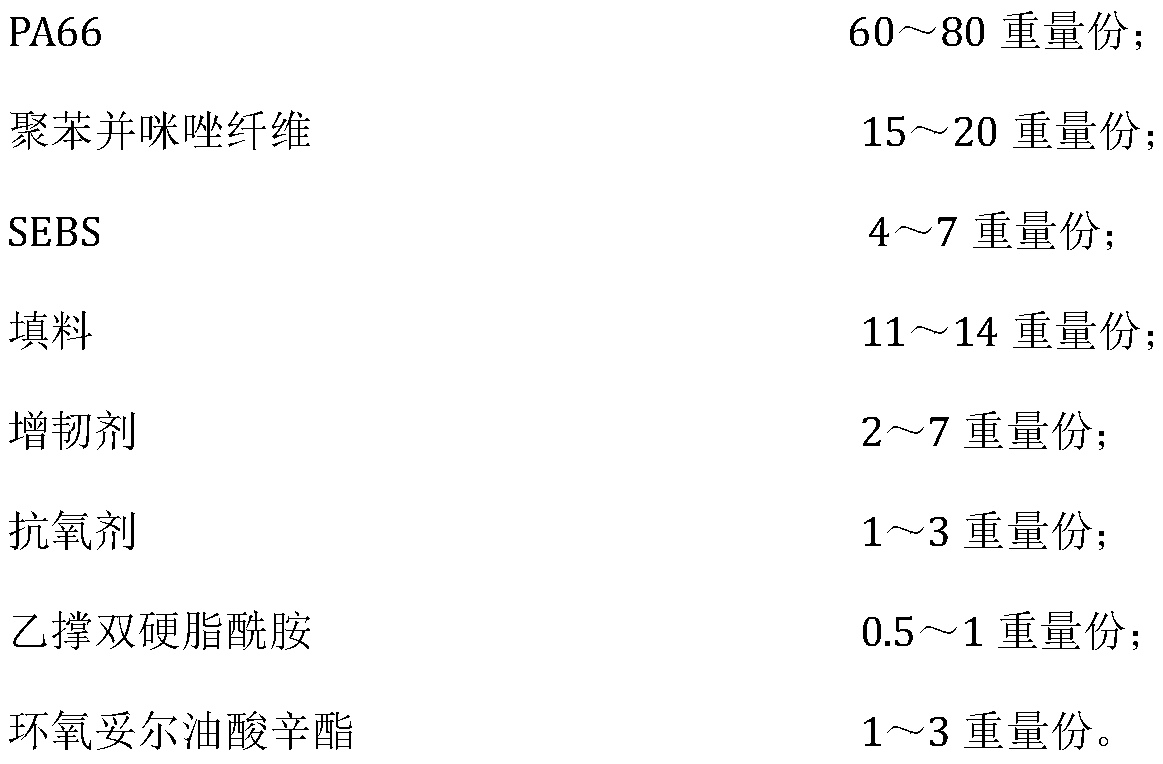

[0037] A high heat-resistant and toughened thermally conductive PA66 material, comprising the following materials by weight:

[0038]

[0039]

[0040] Fillers include 60wt% titanium boride and 40wt% tantalum carbide; tougheners include 60wt% polyvinyl acetate and 40wt% polyvinyl butyral; antioxidants include 20wt% zinc ethyl phenyl dithiocarbamate and 80wt% %N,N-bis(2,4-diiminodiphenyl ether) imine; the number average molecular weight of tetrafluoroethylene-perfluoro(vinyl polyalkoxy sulfonic acid group) ether copolymer is 3600; boronation The particle size of titanium and tantalum carbide is 70nm.

[0041] A method for preparing a high heat-resistant and toughened thermally conductive PA66 material, the preparation method comprising the following steps:

[0042] 1) PA66, SEBS, ethylene bis stearamide, octyl epoxy tall oleate, titanium boride, tantalum carbide, polyvinyl acetate, polyvinyl butyral, zinc ethyl phenyl dithiocarbamate , N, N-bis(2,4-diiminodiphenyl ether) ...

Embodiment 2

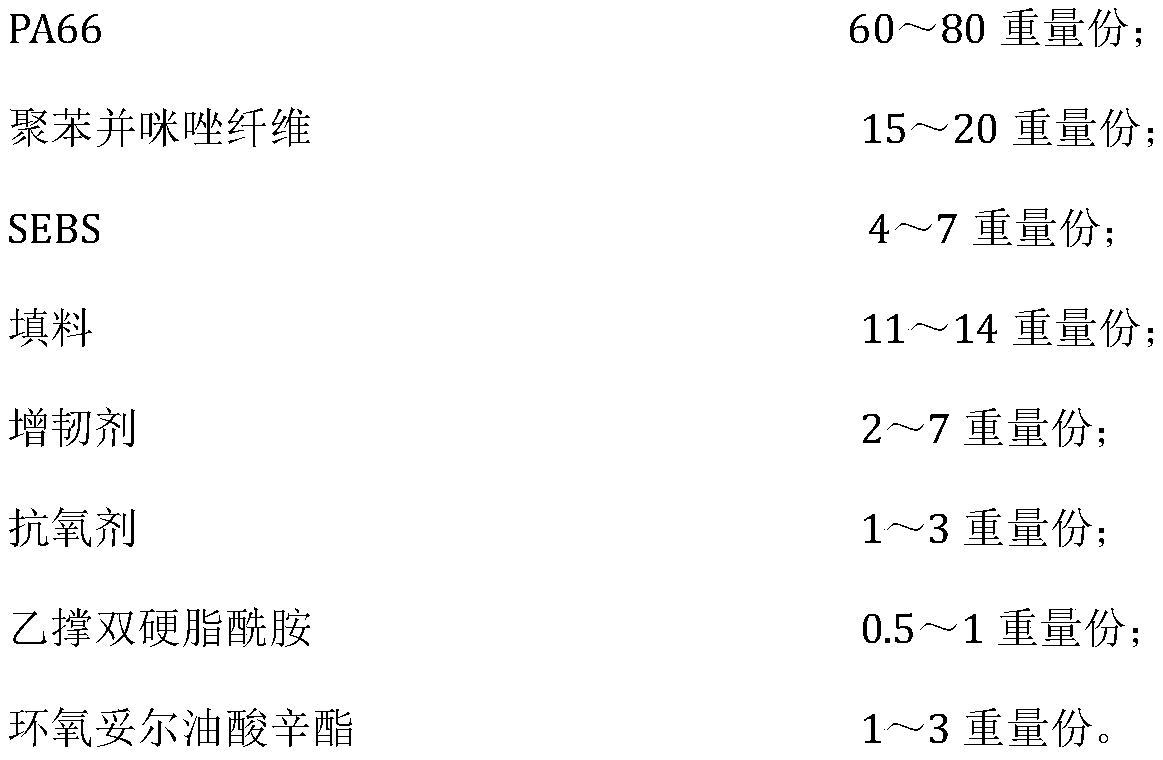

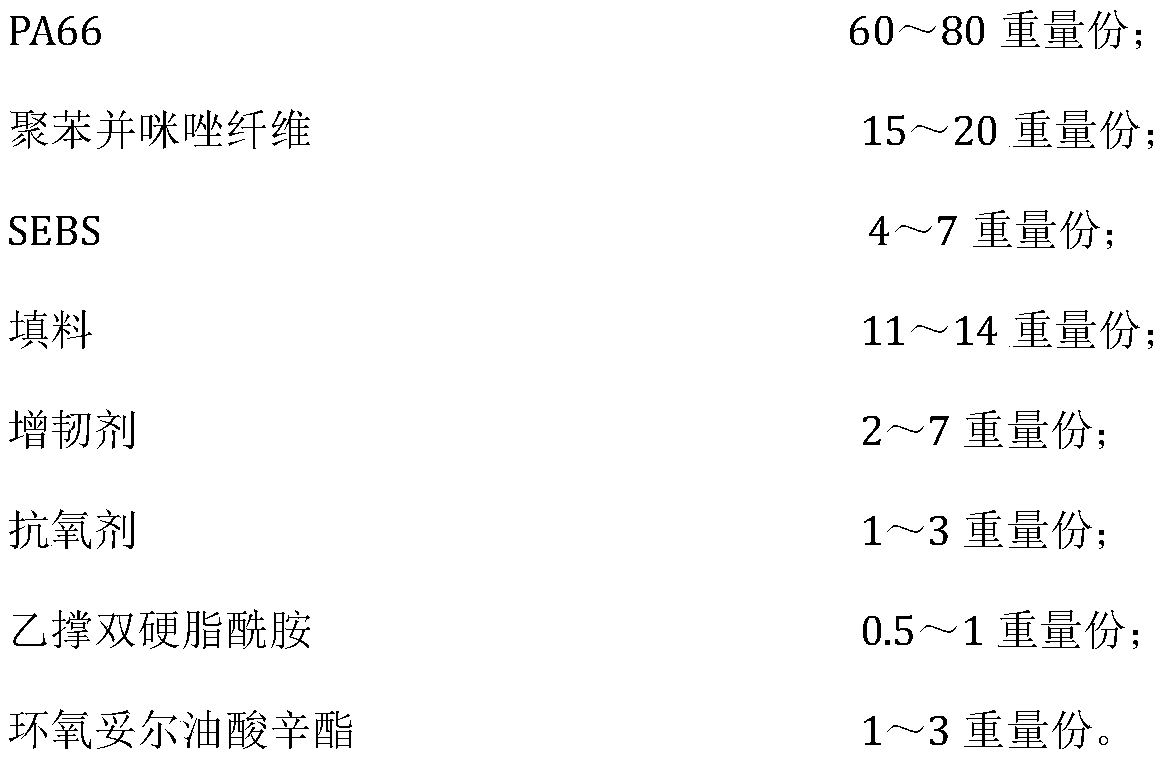

[0044] A high heat-resistant and toughened thermally conductive PA66 material, comprising the following materials by weight:

[0045]

[0046] Fillers include 65wt% titanium boride and 35wt% tantalum carbide; tougheners include 64wt% polyvinyl acetate and 36wt% polyvinyl butyral; antioxidants include 26wt% zinc ethyl phenyl dithiocarbamate and 74wt% %N,N-bis(2,4-diiminodiphenyl ether) imine; the number average molecular weight of tetrafluoroethylene-perfluoro(vinyl polyalkoxy sulfonic acid group) ether copolymer is 4000; boronation The particle size of titanium and tantalum carbide is 80nm.

[0047] A method for preparing a high heat-resistant and toughened thermally conductive PA66 material, the preparation method comprising the following steps:

[0048] 1) PA66, SEBS, ethylene bis stearamide, octyl epoxy tall oleate, titanium boride, tantalum carbide, polyvinyl acetate, polyvinyl butyral, zinc ethyl phenyl dithiocarbamate , N, N-bis(2,4-diiminodiphenyl ether) imine, di-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com