Method and device for melt spinning, treating and coiling synthetic filament

A filament and suction device technology, applied in the field of devices implementing the method, can solve the problems of unsuitability for filament wetting, loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

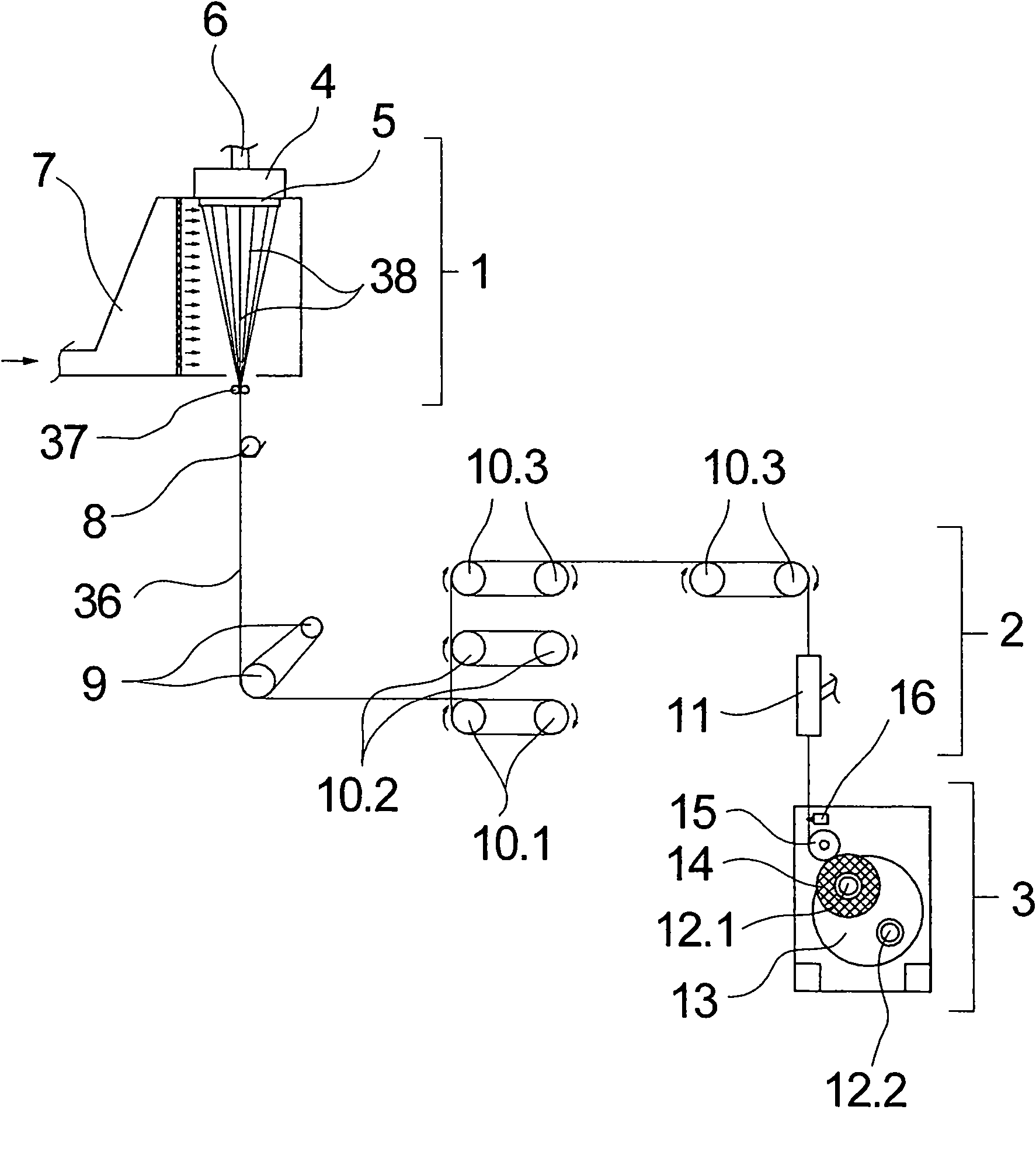

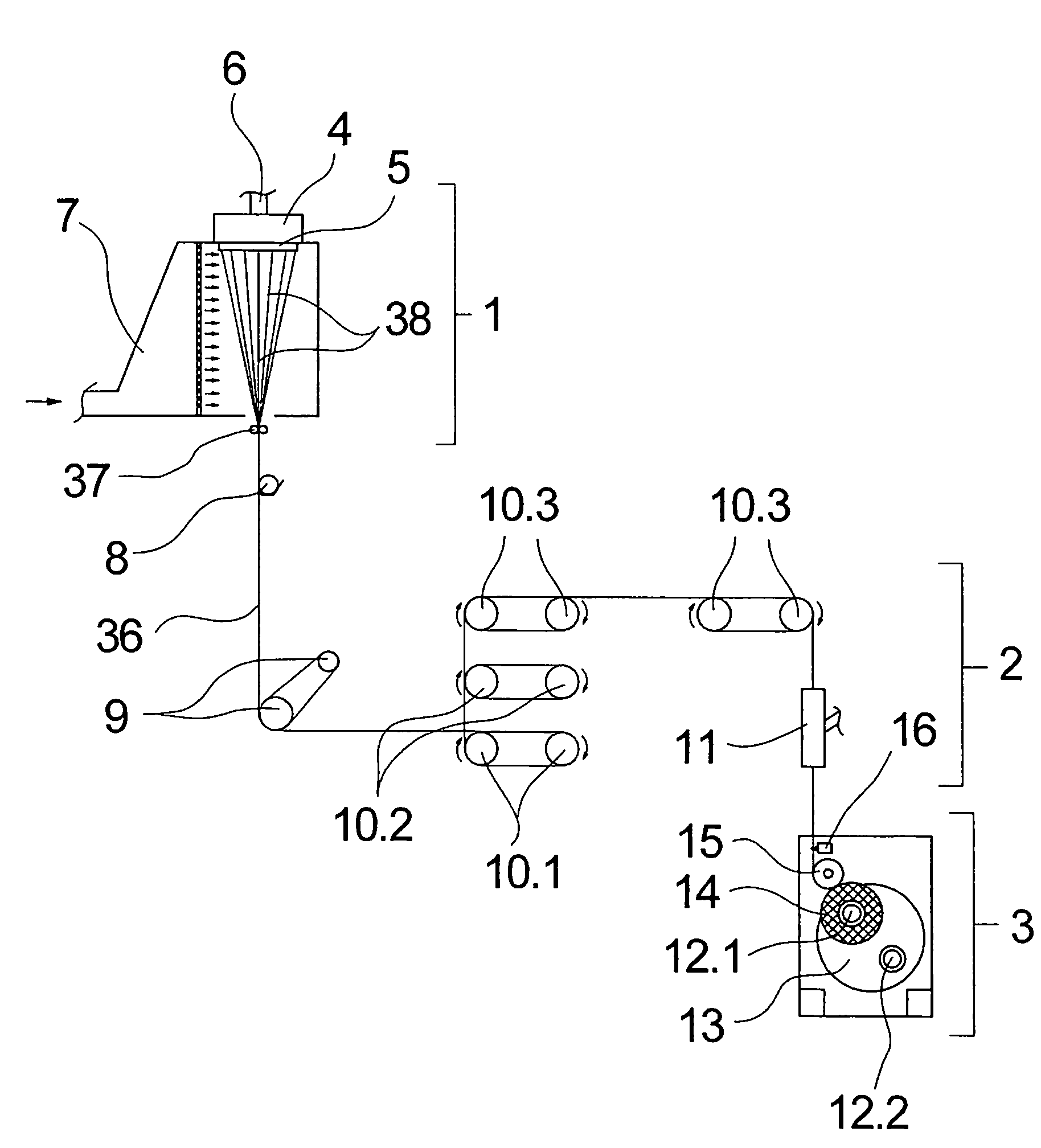

[0023] figure 1 An exemplary embodiment of the device according to the invention for carrying out the method according to the invention for producing synthetic filaments, in particular to form IDY filaments, is shown in a view. This exemplary embodiment shows a spinning device 1 , a processing device 2 and a winding device 3 , which are arranged one behind the other in the yarn flow. These devices are typically used to melt spin, process and wind multiple parallel-guided filaments. but figure 1 The filament flow for only one filament is shown in .

[0024] For the melt spinning of multi-filament filaments, the spinning device 1 has a heatable spinning head 4 which has a spinneret 5 with a large number of nozzle holes on its underside and a melting nozzle on its upper side. body entrance 6. The melt inlet 6 is connected to a melt source (not shown here), for example an extruder. Further components for guiding and conveying the melt, such as spinning pumps, are usually arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com