Surface texture measuring machine and a surface texture measuring method

一种表面性质、测定物的技术,应用在测量装置、机械测量装置、采用机械装置等方向,能够解决耗费时间、测定物划伤等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0088] Figure 1 to Figure 5 )>

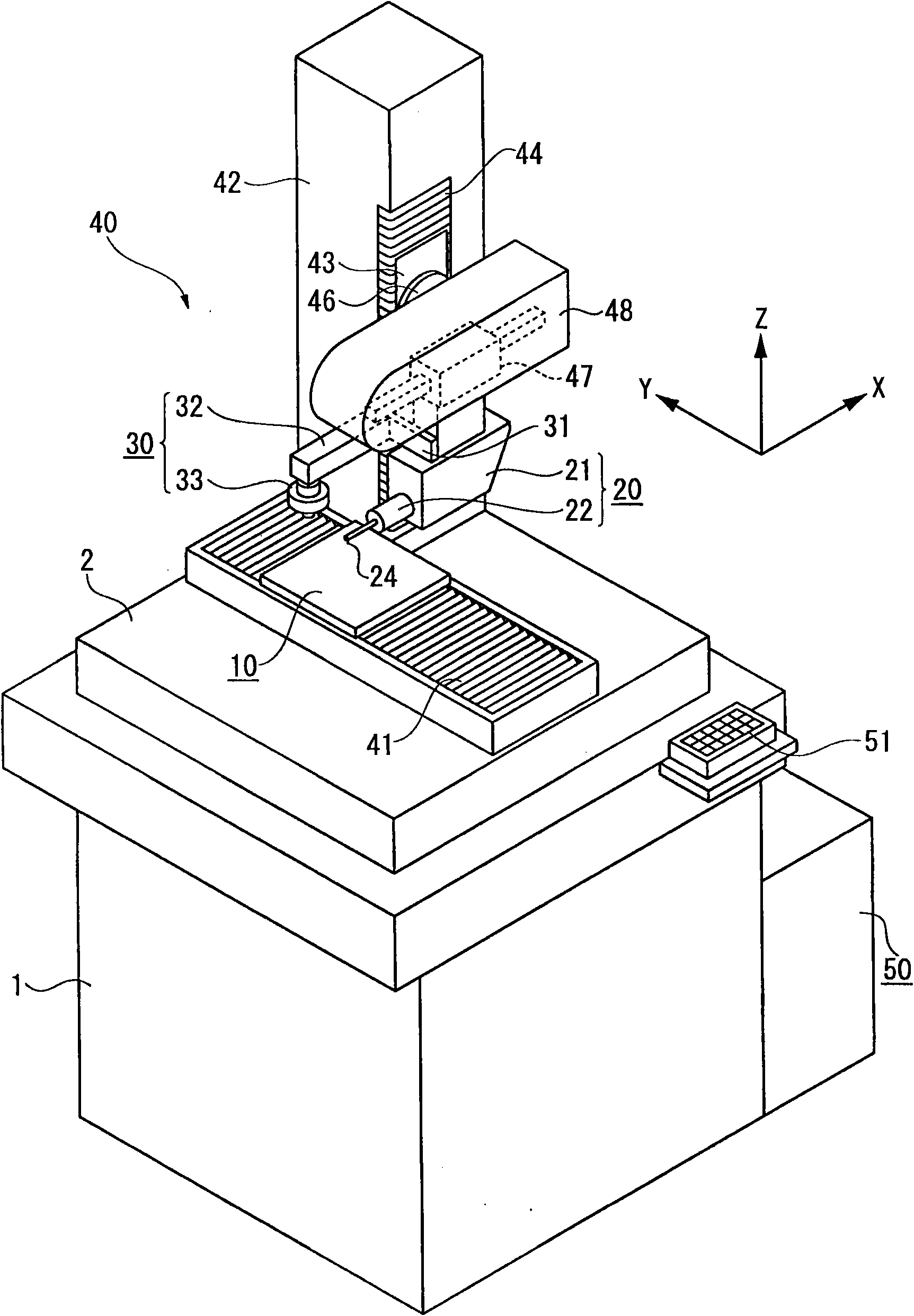

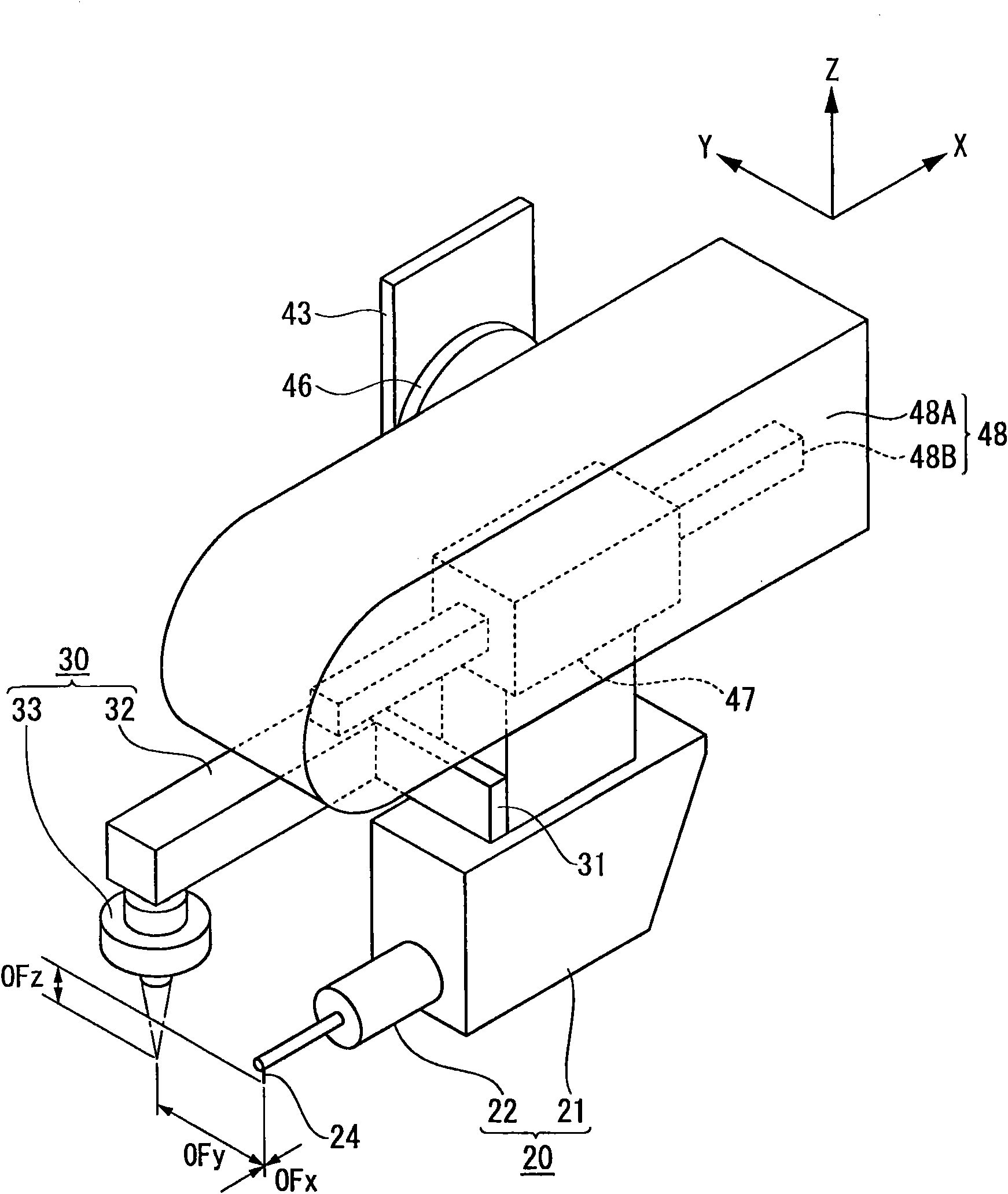

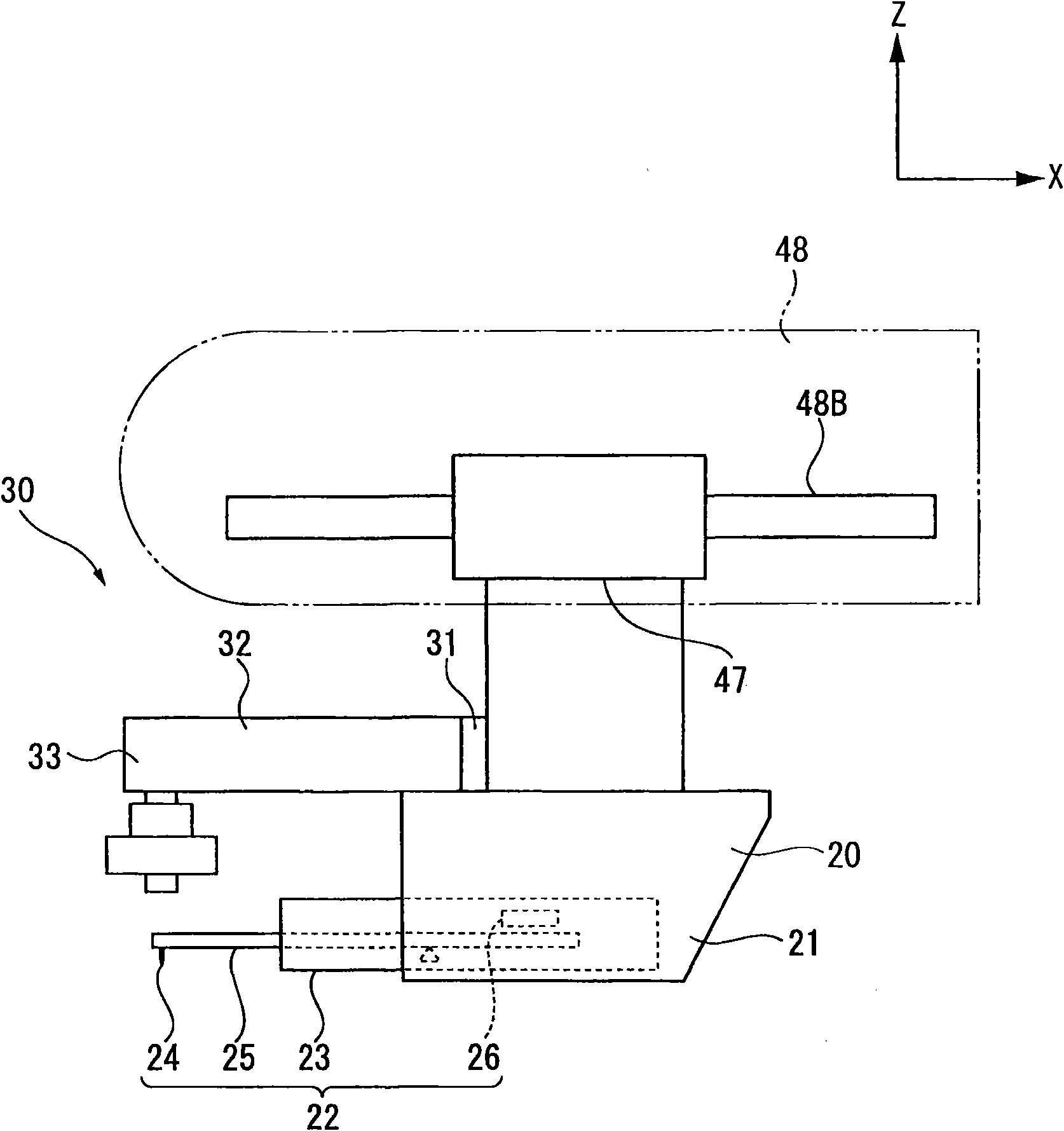

[0089] Such as figure 1 and figure 2 As shown, the surface property and shape measuring machine of this embodiment has: a setting table 1, a base 2 fixed on the setting table 1, a workbench 10 carried on the base 2 and an object to be measured thereon, A contact detector 20 with a probe 24 that is in contact with the surface of the object to be measured, an image detector 30 that captures an image of the surface of the object to be measured, and a relative movement of the contact detector 20 and the image detector 30 to the table 10 The relative movement mechanism 40, the control device 50.

[0090] The relative moving mechanism 40 includes: a Y-axis drive mechanism 41 as a first moving mechanism that is installed between the base 2 and the table 10 to move the table 10 in one direction (Y-axis direction) in the horizontal direction; The column 42 on the upper surface of the base 2, the Z slide block 43 as an elevating member which is arr...

no. 2 example

[0141] In the description of the second embodiment, the same reference numerals are assigned to the same constituent elements as those of the first embodiment, and description thereof will be omitted.

[0142] The surface property and shape measuring machine of the second embodiment can adjust the posture of the object to be measured to a posture parallel or perpendicular to the specified measurement axis, such as Figure 20 and Figure 21 As shown, a rotary table 10A is added to the surface property and shape measuring machine of the first embodiment.

[0143] The turntable 10A is installed on the table 10 and rotates according to the command of the control device 50 . Thereby, the object W to be measured is rotated in the horizontal plane (in the XY plane). In this example, the object W to be measured is cylindrical.

[0144] The image probe 30 has an appropriate structure for positioning the object W to be measured at the focal position of the objective lens 35 in additi...

no. 3 example

[0175] In the description of the third embodiment, the same reference numerals are assigned to the same constituent elements as those of the first embodiment, and description thereof will be omitted.

[0176] The surface property and shape measuring machine of the third embodiment can automatically set the probe of the contact detector to the measurement start position of the object based on the image of the object captured by the image sensor. Such as Figure 32 and Figure 33 As shown, the structures of the image probe 30 and the control device 50 are different from the surface property and shape measuring machine of the first embodiment.

[0177] The image probe 30 of the present embodiment includes: a cylindrical probe body 32 integrally connected to the X slider 47 together with the contact detector 20 via a connecting member 31; 24 An axis perpendicular to the direction in which the contact detector 20 and the table 10 move relative to each other (X-axis direction) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com