Method for replacing optical fiber composite overhead ground wire or common overhead ground wire without power cut

An overhead ground wire and optical fiber composite technology, which is applied in the configuration of ground wires, overhead line/cable equipment, etc., can solve the problem that the ground wire is easy to touch the power line, etc., and achieve the effect of reducing the trouble of approval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

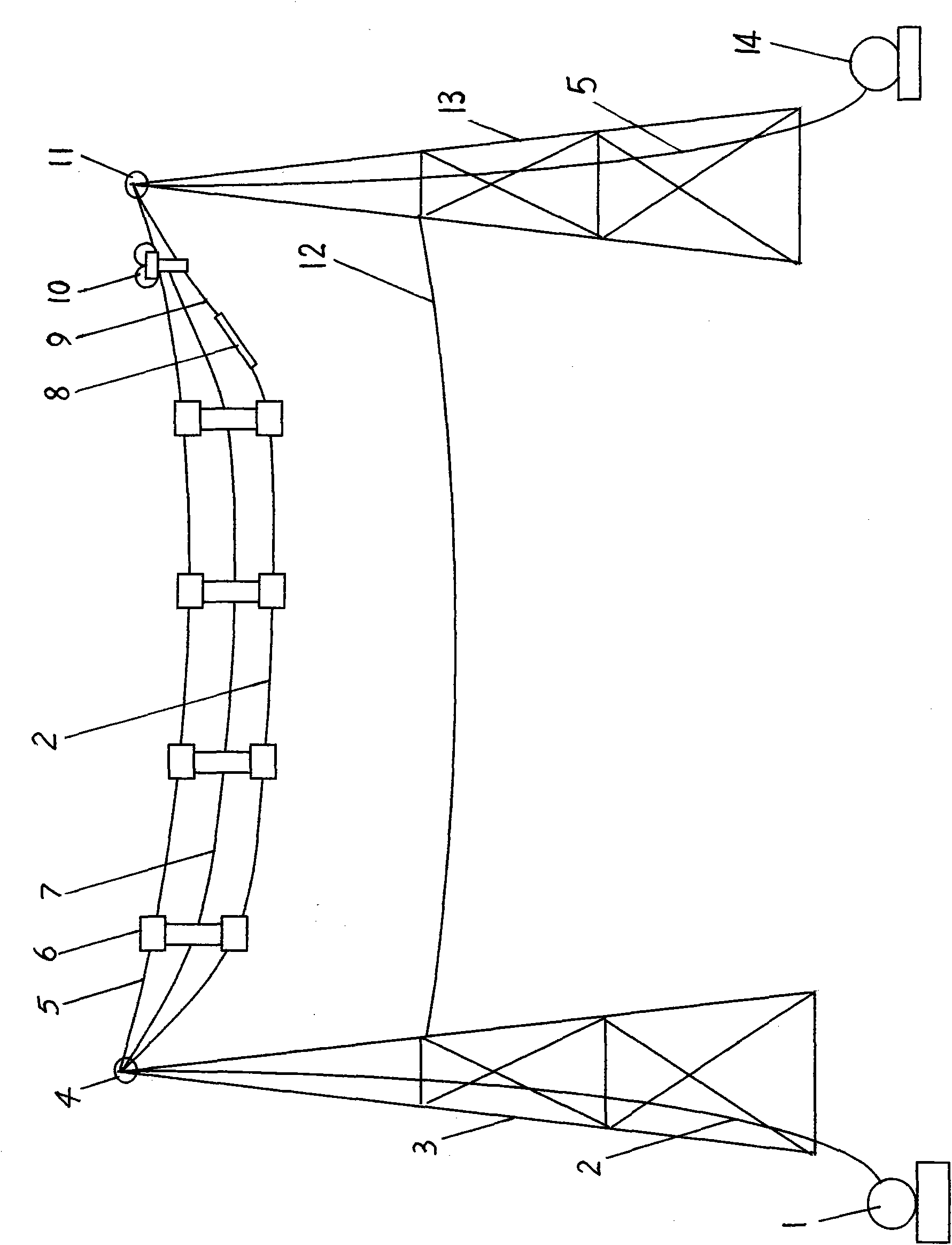

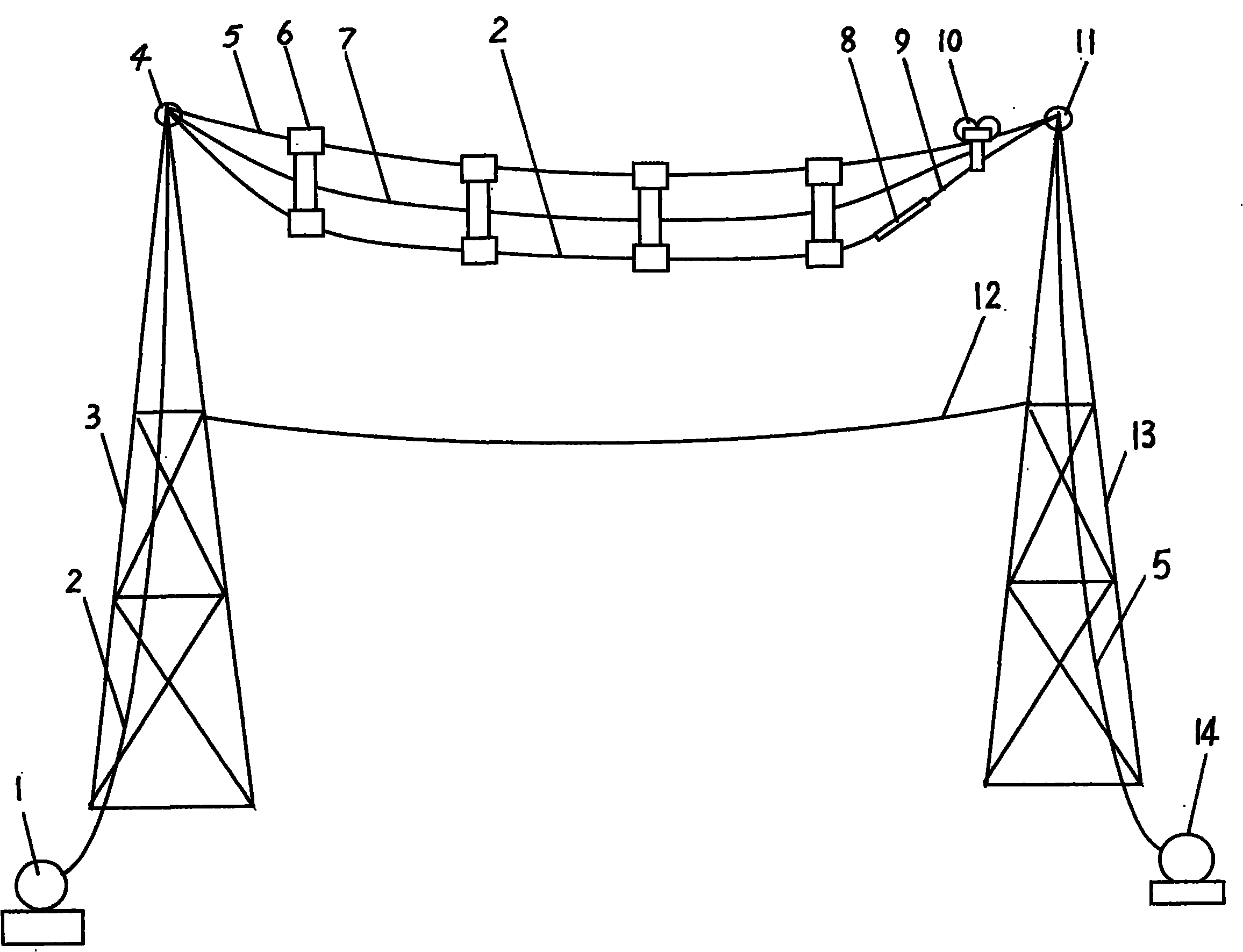

[0008] refer to figure 1 , on the old ground wire 5 between the iron tower 3 at one end and the iron tower 13 at the other end, a plurality of hanging pulleys 6 and a wire tractor 10 are hung, between the hanging pulley 6 and the iron tower 3 at one end, between adjacent hanging pulleys 6 Between the wire tractor 10 and the hanging pulley 6, all are fixedly connected with the connecting rope 7, and the interval length is 15 meters-20 meters. Pass through the hole at the bottom of each suspension pulley 6 after the top, and connect with the insulating rope 9 on the wire tractor 10 with a clamp 8, start the wire tractor 10 to pull the new ground wire 2 to the other end iron tower 13 , the wire tractor 10 reaches the top of the iron tower 13 at the other end, takes off the old ground wire 5 and installs it on the pulleys 4 and 11 of the iron towers at both ends, stretches the new ground wire 2 to a specified sag and connects it to the iron tower 3. On 13, fix the connecting rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com