Positioning installing structure for stator core of motor and base

A motor stator and stator core technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of inability to absorb vibration, weak welding, and potential safety hazards, so as to reduce rework, facilitate connection, and ensure normal operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

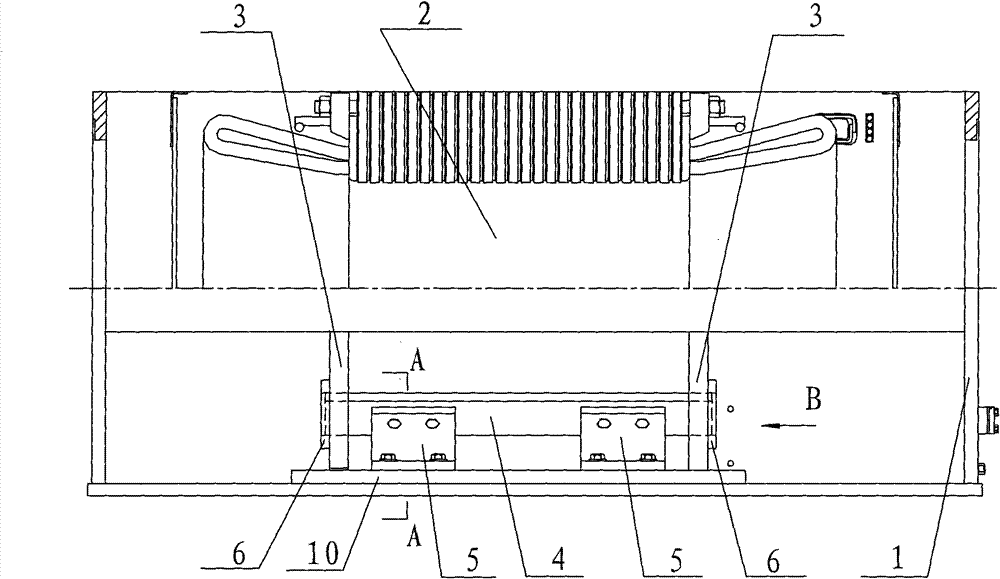

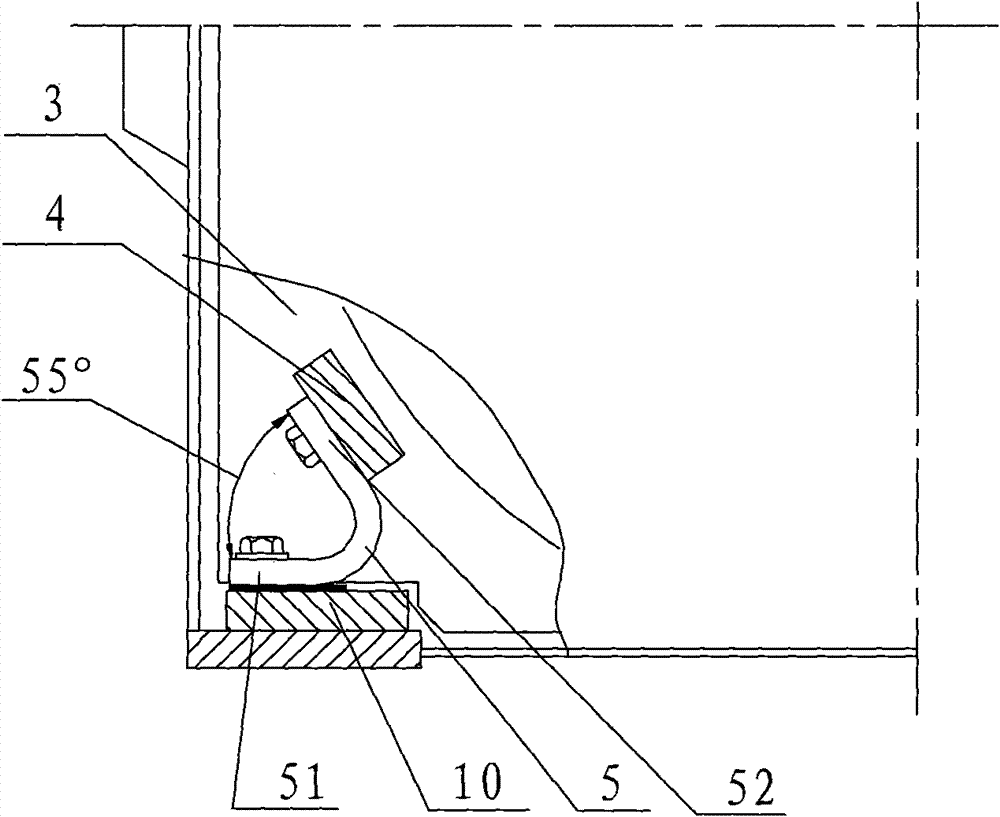

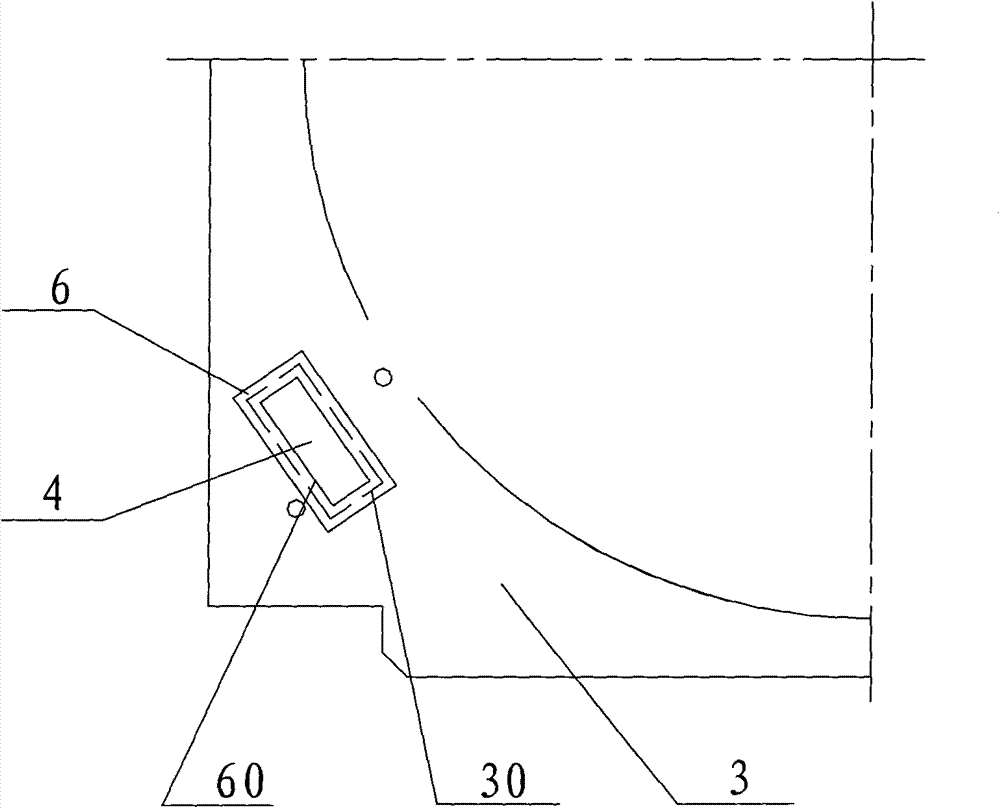

[0018] see figure 2 with image 3 , a positioning installation structure of a motor stator core and a machine base according to the present invention, comprising a machine base 1, a stator core 2, two end pressure plates 3, a support rib 4, two elastic feet 5 and two positioning sleeve plates 6 ,in,

[0019] The end plate 3 is located at both ends of the stator core 2; the cross section of the support rib 4 is rectangular;

[0020] The lower side of the end plate 3 is provided with a rectangular hole 30 with an angle of 55° with the inner bottom surface 10 of the machine base 1. The length and width of the rectangular hole 30 are respectively 18 to 18% larger than the length and width of the section of the support rib 4. 22mm;

[0021] The supporting ribs 4 are bridged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com