Method for processing fragile material substrate

A technology of brittle material substrates and processing methods, which is applied in stone processing equipment, stone processing tools, metal processing equipment, etc., and can solve the problems of substrate glass shavings and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] (device configuration)

[0075] Hereinafter, embodiments of the present invention will be described based on the drawings.

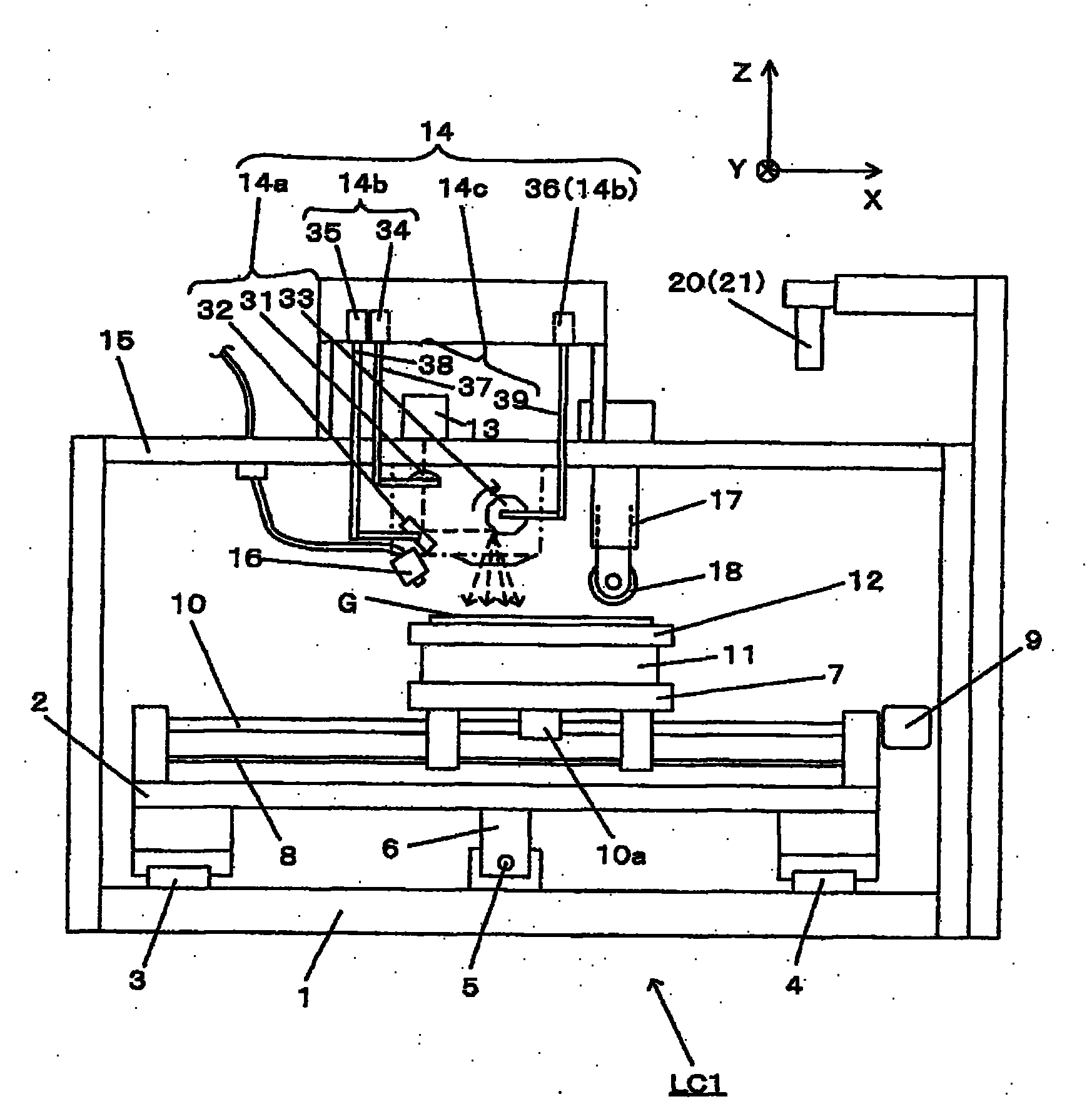

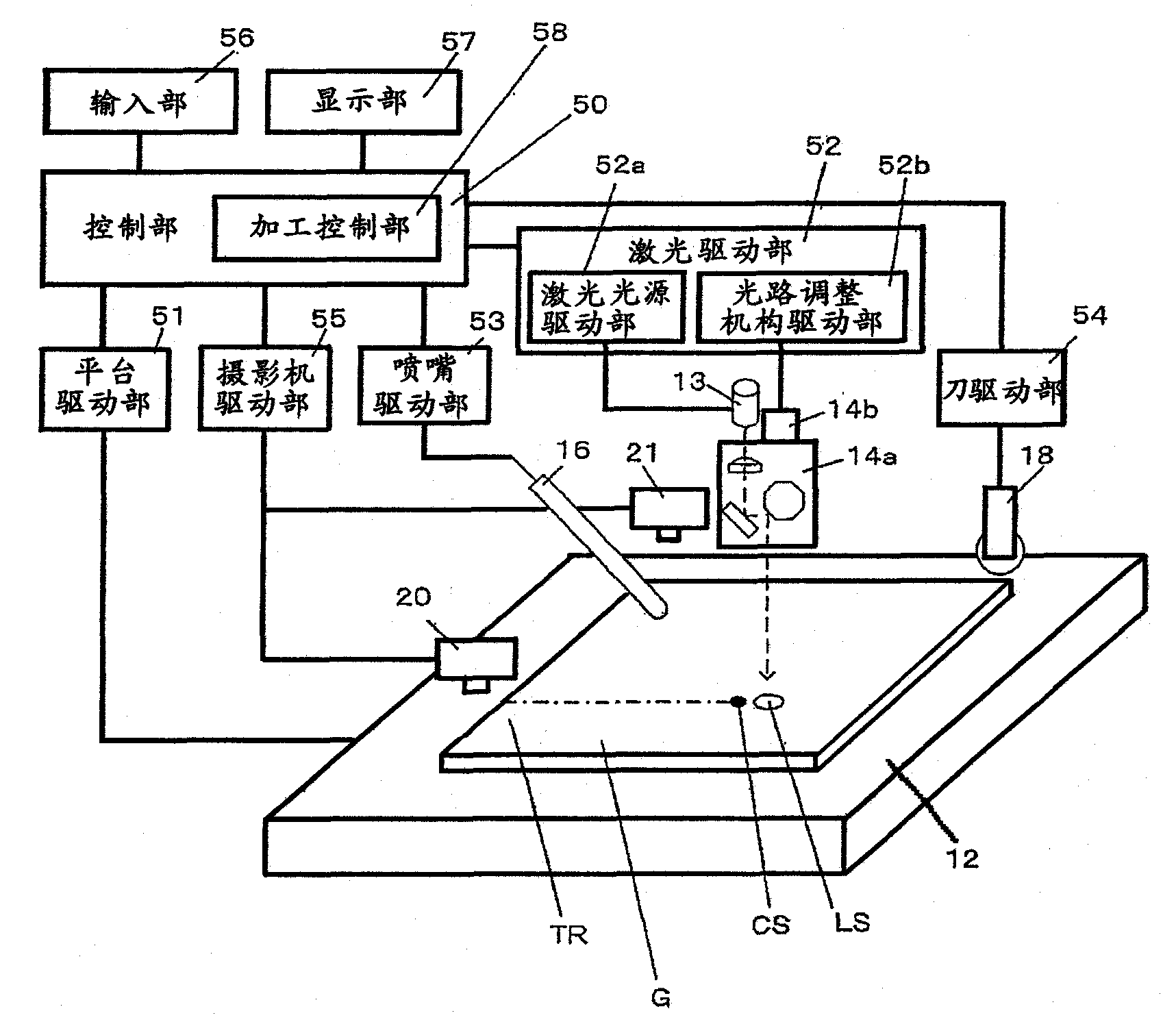

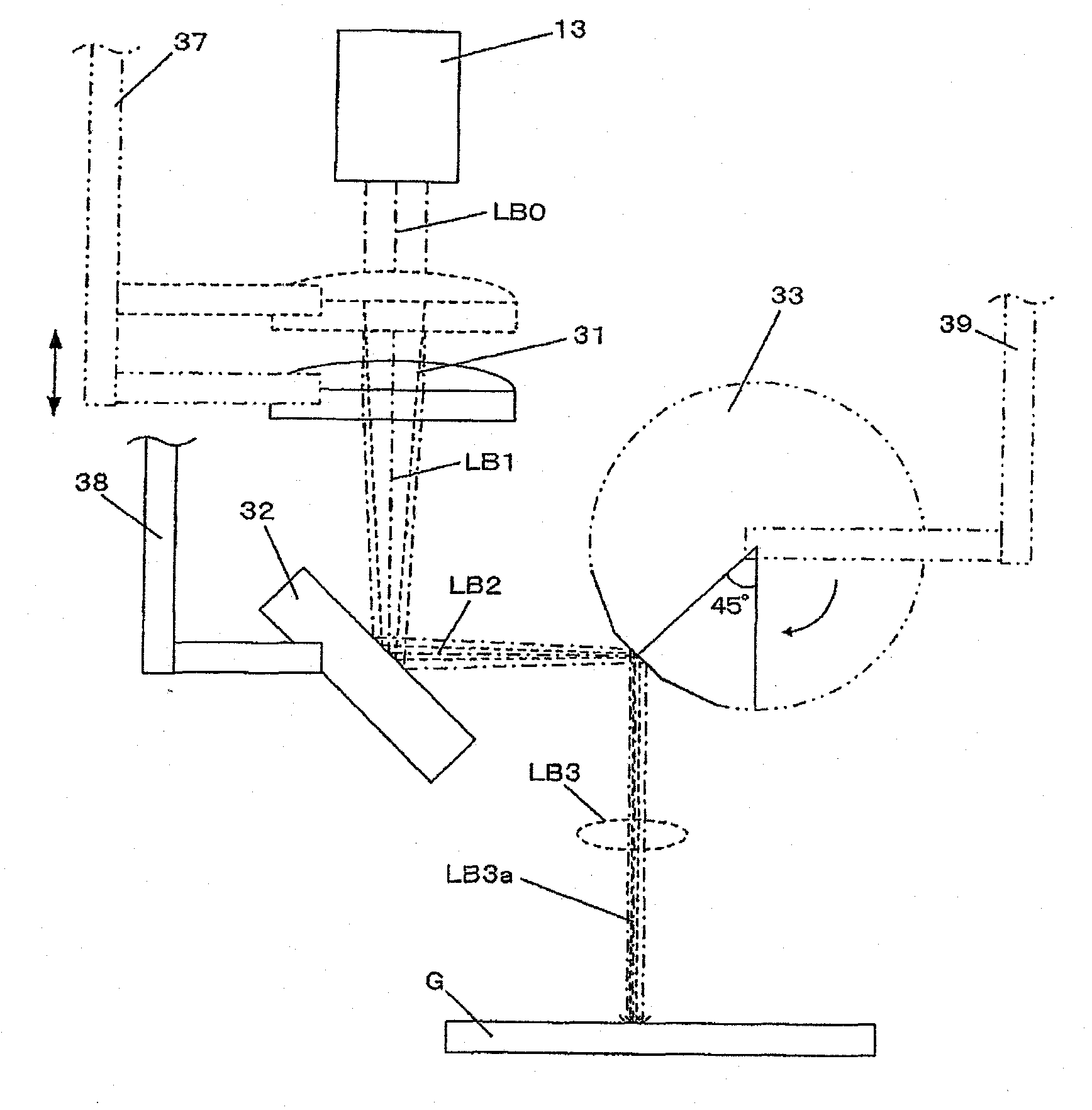

[0076] First, an example of a substrate processing apparatus used for carrying out the processing method of the present invention will be described. figure 1 It is a schematic configuration diagram of a laser cutting device LC1 according to an embodiment of the present invention. figure 2 for display figure 1 The block diagram of the control system of the laser cutting device LC1.

[0077] first based on figure 1 The overall configuration of the laser cutting device LC1 will be described.

[0078] A pair of guide rails 3 and 4 arranged in parallel on the horizontal platform 1 are arranged on the figure 1 The sliding platform 2 that moves back and forth in the front and rear direction (hereinafter referred to as the Y direction) of the paper. A lead screw 5 is disposed between the two guide rails 3 and 4 along the front and rear directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com