Polishiing apparatus and polishiing method

A technology of a grinding device and a grinding method, which is applied to grinding machines, grinding workpiece supports, grinding machine parts, etc., can solve problems such as defective products, and achieve the effects of low frictional resistance, preventing damage to substrates, and preventing deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] Embodiment 1

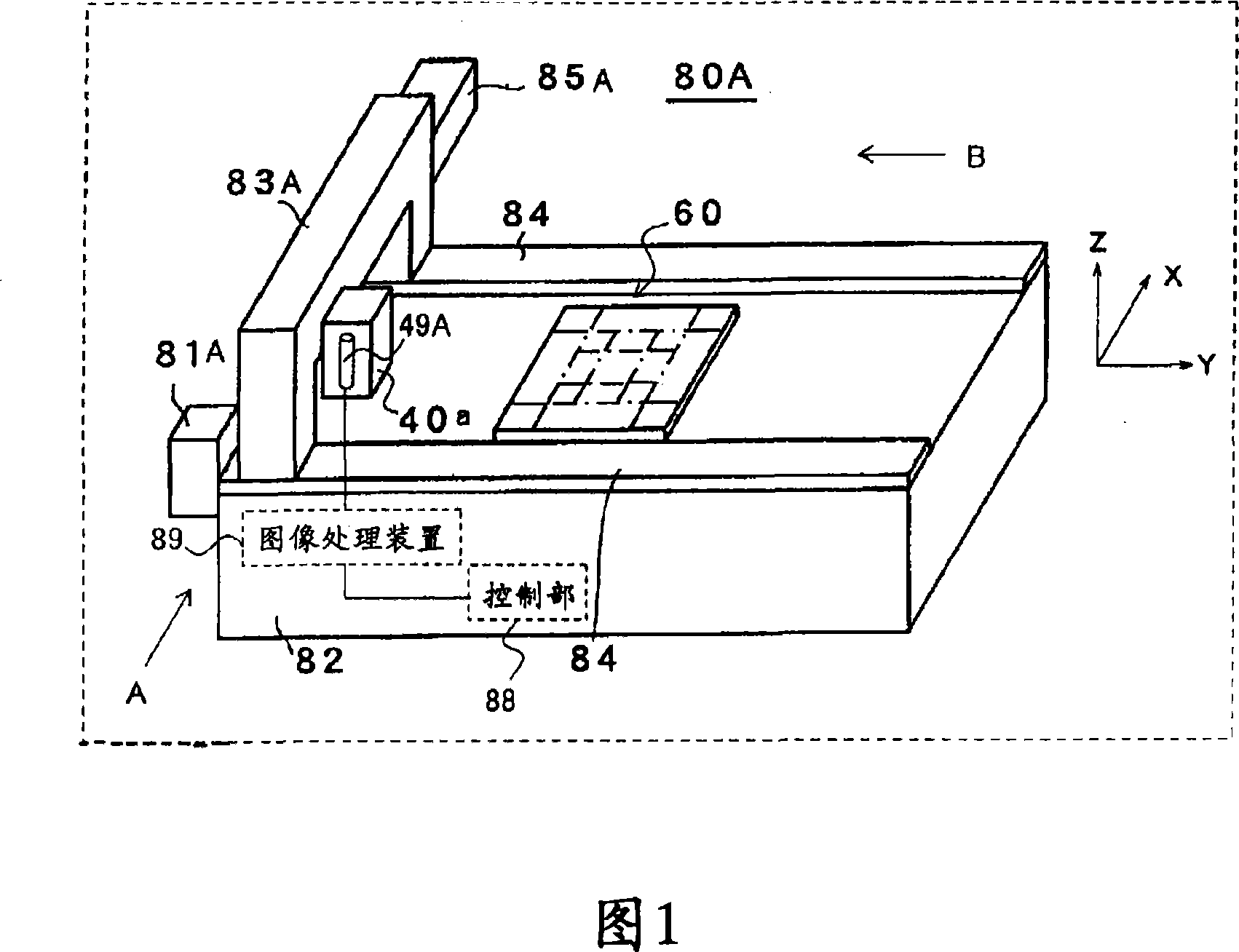

[0114] Fig. 1 is a schematic perspective view showing a schematic configuration of a polishing apparatus according to Embodiment 1 of the present invention. The grinding device 80A is provided with a base 82, a stage unit 60 disposed on the base 82 for holding a substrate whose end surface is to be ground, and a grinding unit 40a for grinding the end surface of the substrate held by the stage unit 60. , a grinding unit holder 83A for holding the grinding unit 40a, a pair of LM guides 84 for guiding the grinding unit holder 83A, a grinding unit holder for moving the grinding unit holder 83A along the respective LM guides 84 Moving mechanism 81A, polishing unit moving mechanism 85A for moving polishing unit 40a held by polishing unit holder 83A, imaging device 49A attached to polishing unit 40a, control unit 88, and image processing device 89.

[0115] The base 82 has a horizontal rectangular shape above. In addition, in the following description, the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com