Motorcycle tire

A tire and tire crown technology, applied to motorcycle tires, motorcycles, wheels, etc., can solve the problems of worn tire profile aesthetics, reducing tire effective life, and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

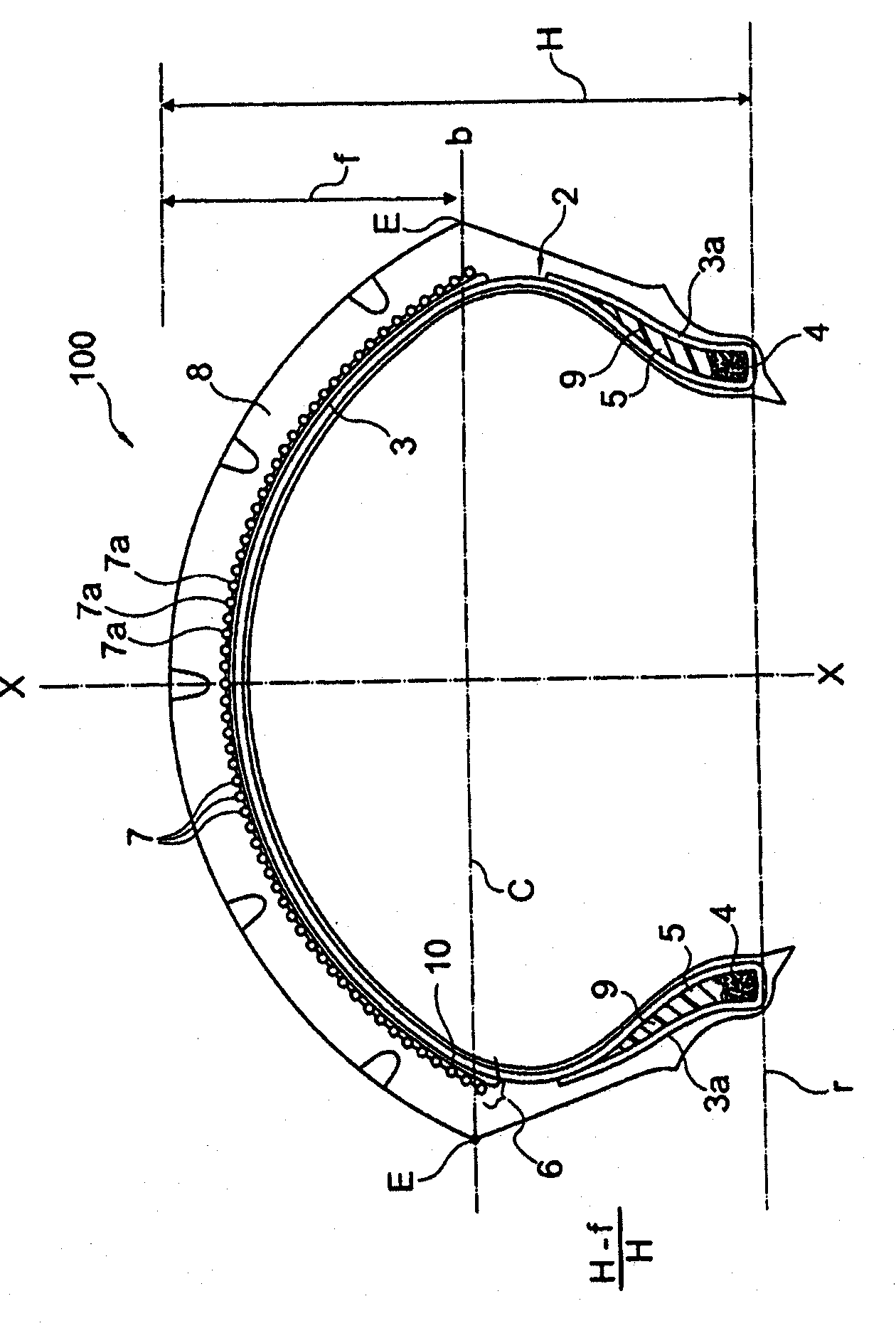

[0065] With reference to the above-mentioned figures, 100 denotes a complete motor vehicle tire according to the invention.

[0066] The motor vehicle tire 100 comprises a carcass structure 2 formed of at least one carcass ply 3 . The carcass ply 3 is made of elastomeric material and comprises a plurality of reinforcing elements arranged parallel to each other.

[0067] The carcass ply 3 engages by its opposite circumferential edges at least one annular reinforcing structure 9 .

[0068] In particular, the opposite side edges 3 a of the carcass ply 3 are folded back around an annular reinforcing structure, which is a so-called bead wire.

[0069] On the axially outermost periphery of the bead wire 4 is applied a tapered elastomeric bead filler 5 which occupies the space between the carcass ply 3 and the carcass ply 3 The space defined between the corresponding back-turned lateral edges 3a.

[0070] As is well known, the region of the tire comprising the bead wire 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com