Determination of the movement of a synchronous machine

A synchronous motor, synchronous motor technology, applied in motor control, electronic commutation motor control, elevator and other directions, to simplify the measurement layout, improve the parking accuracy, improve the accuracy of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

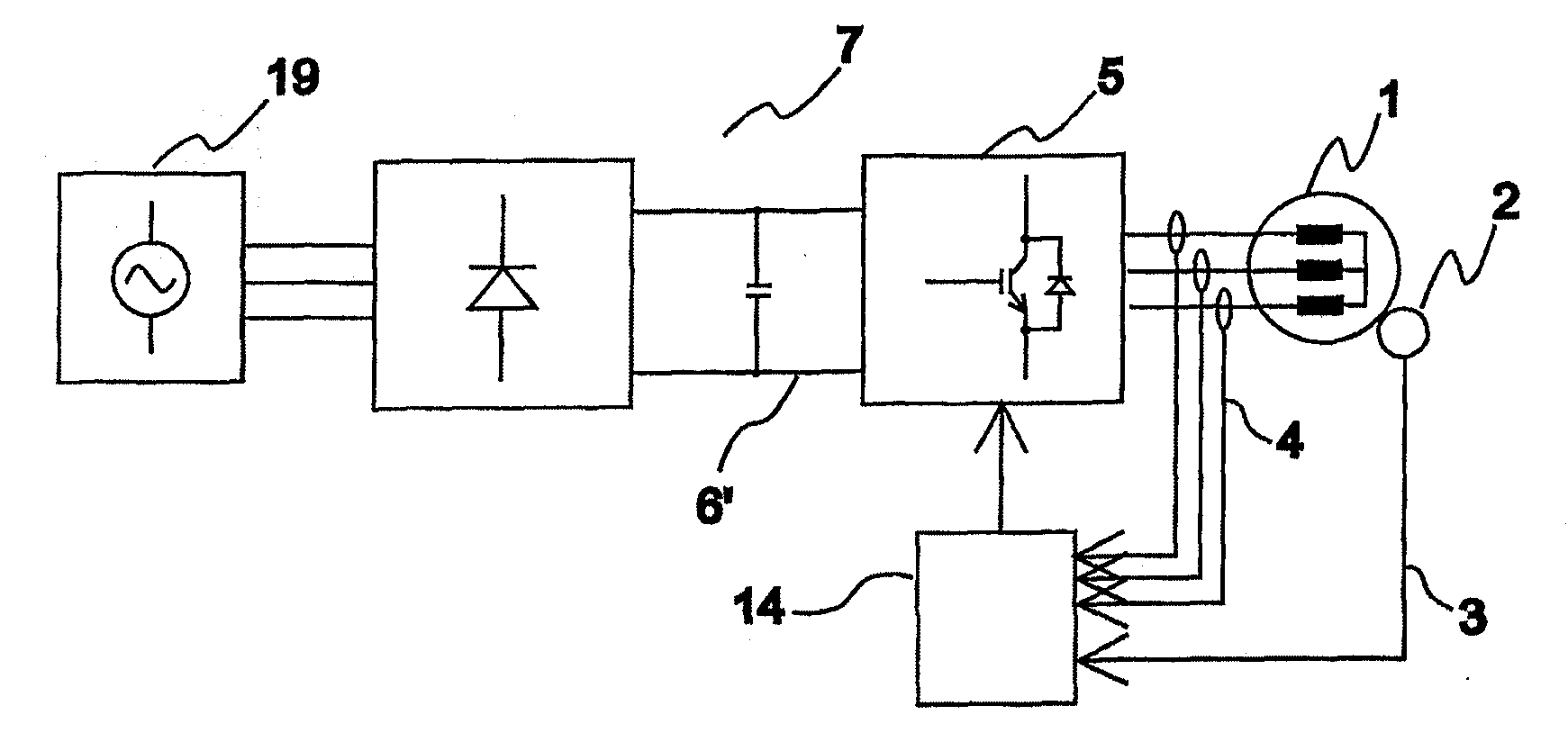

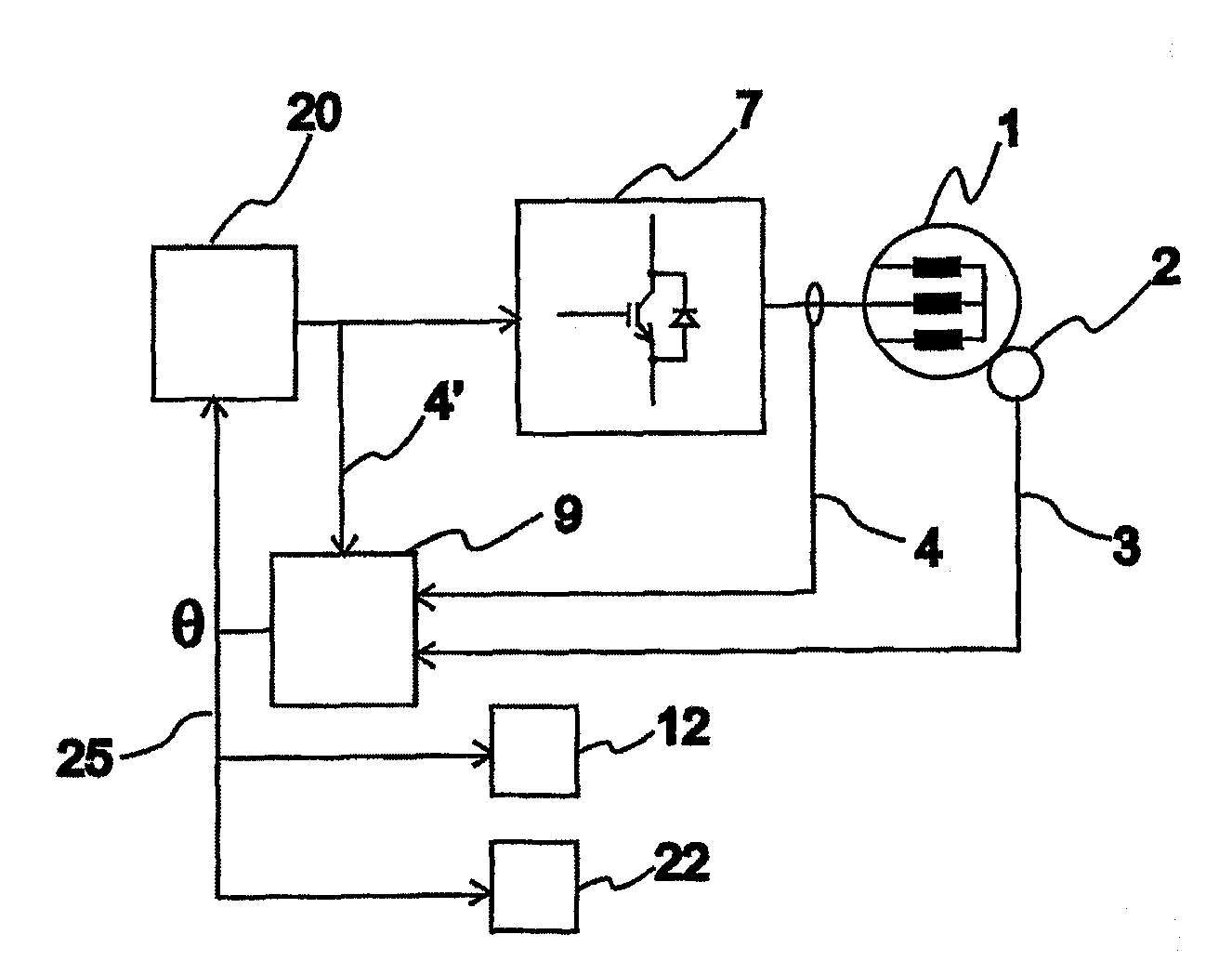

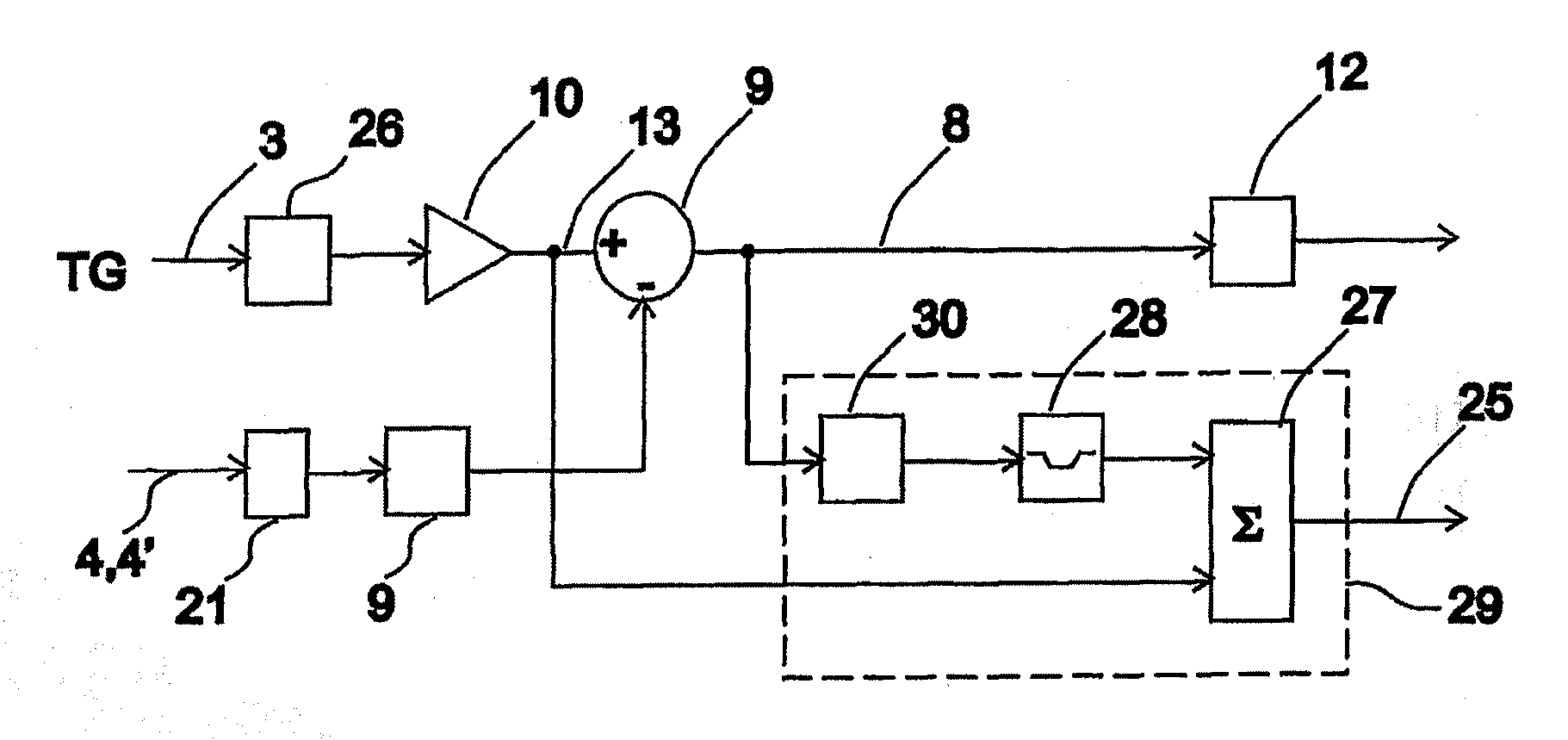

[0047] figure 1 A frequency converter 7 is shown, which comprises the device according to the invention for determining the movement of a synchronous machine. The frequency converter 7 is suitable for providing power between the synchronous machine 1 and the grid 19 . The frequency converter comprises a load bridge 5 connected to the stator windings of the synchronous machine. The control part 14 of the frequency converter is adapted to control the solid state switches of the load bridge 5 to form a variable amplitude and variable frequency control voltage to each phase of the stator winding of the synchronous machine. The encoder 2 is mounted to the outer rim of the rotor of the synchronous motor via a friction wheel, in which case, when the rotor rotates, the rotary shaft of the encoder fixed to the friction wheel also rotates via the friction wheel. The encoder comprises an output for a motion signal 3 representing the motion of the rotor of the synchronous machine.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com