Hydraulic damping cylinder and pneumatic driving device and wiper using the damping cylinder

A hydraulic damping and pneumatic drive technology, applied in the fields of pneumatic drive devices, wipers, and hydraulic damping cylinders, can solve problems such as failure to meet the requirements of EMUs, difficult control of piston feed speed, and unstable swing of wipers, etc. Motion stability and stop accuracy, simple action mode control, and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

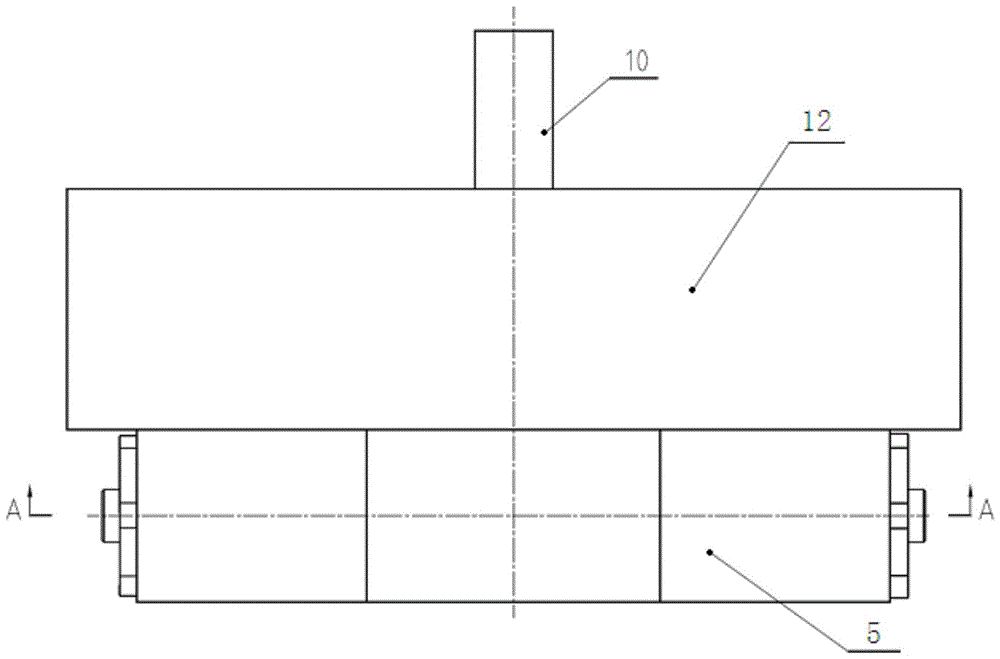

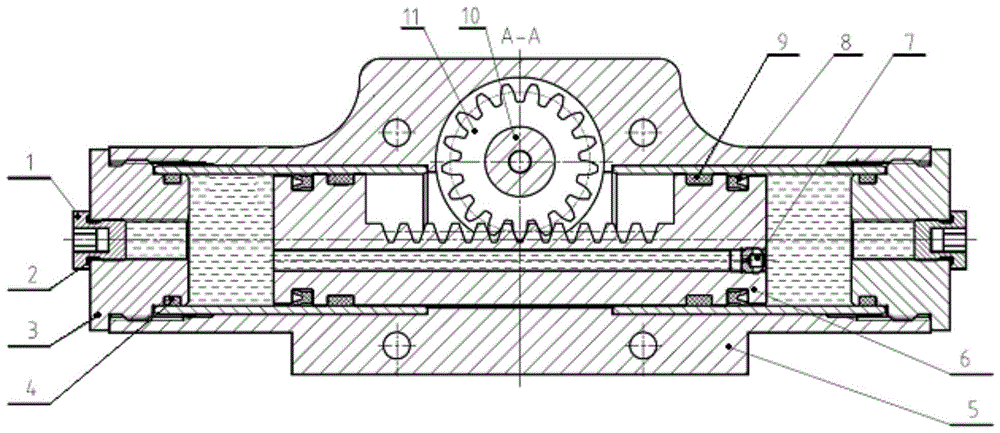

[0019] Such as figure 2 The hydraulic damping cylinder shown includes a damping cylinder and a damping piston 6 that moves left and right in the piston cavity of the damping cylinder. The inner damping gear 11 is meshed for transmission, and the inner hole of the damping gear is the mounting hole of the corresponding power output shaft.

[0020] The damping cylinder body includes the damping cylinder body and the cylinder heads 3 installed on the left and right ends of the damping cylinder body. In order to facilitate disassembly and assembly, the two cylinder heads are screw-mounted on the damping cylinder body 5, and there are oil injection holes running through the two cylinder heads. hole, screw-fit plug 1 on the oil hole. The damping piston 6 divides the damping cylinder into two oil chambers, that is, the left oil chamber and the right oil chamber respectively located at the left and right ends of the damping piston. A cylinder head seal ring 4 is installed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com