Method for desulfurizing high-concentration flue gas

A high-concentration, flue gas technology, used in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as inability to be industrially adopted, and achieve the effects of easy operation, improved value, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

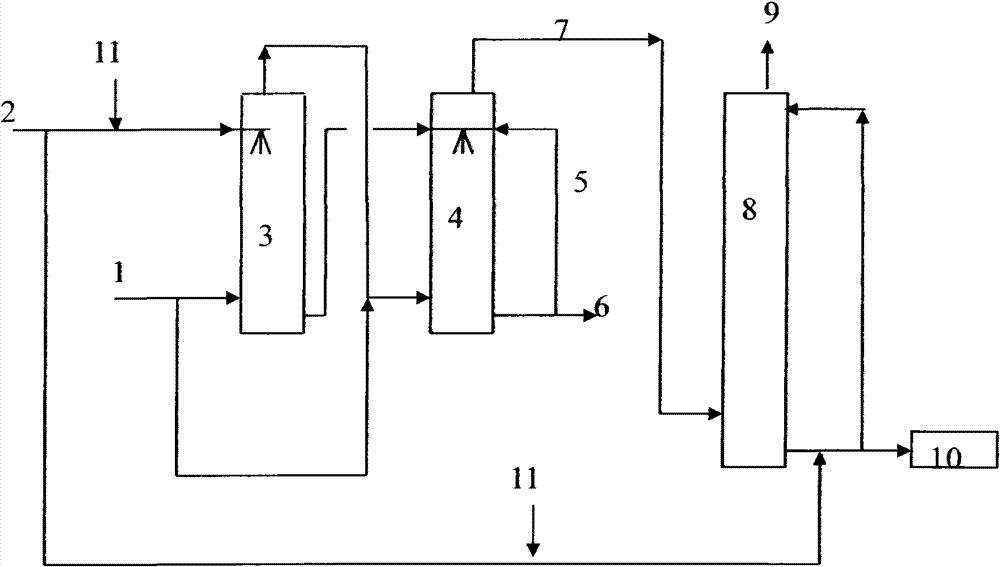

[0020] according to figure 1 In the process shown, the lye uses a sodium hydroxide solution with a weight concentration of 10% to 30%, and when it is used for flue gas deoxidation and flue gas desulfurization, appropriate amount of industrial water is added respectively. A catalytic gasoline adsorption desulfurization adsorbent high concentration regenerated flue gas (main properties: sulfur dioxide concentration is 50000 ~ 75000mg / m 3 , the oxygen content is 3000~6000mg / m 3 ), adopt the inventive method to process, and concrete operating conditions and results are shown in Table 1.

[0021] Table 1 High SO 2 Concentration hypoxic flue gas treatment conditions and results

[0022] Operating Conditions and Results

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap