Multi-tow fiber preimpregnation laying device

A tow fiber and equipment technology, applied in the field of multi-tow fiber prepreg laying equipment, can solve the problems of long production cycle, easy cracks, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

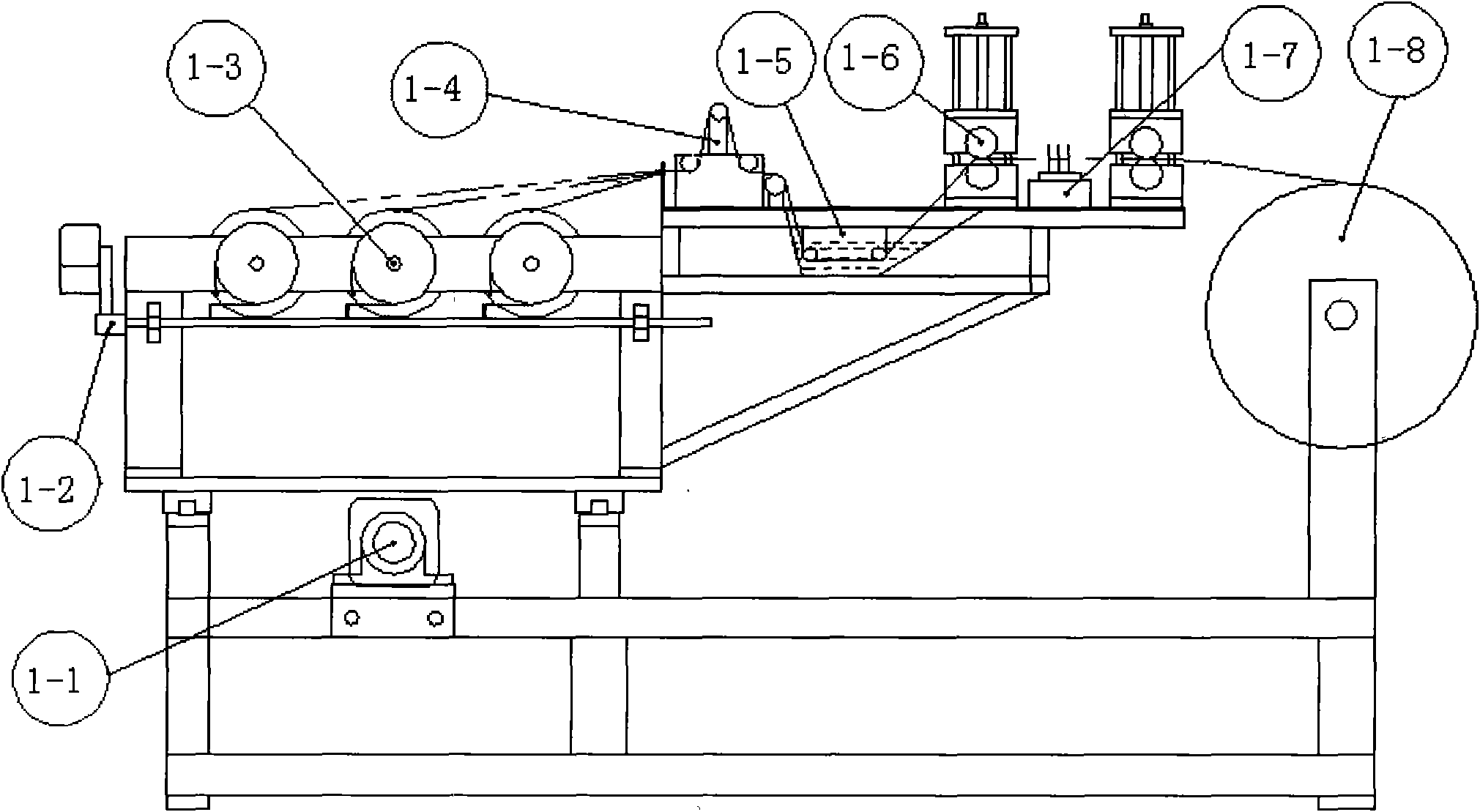

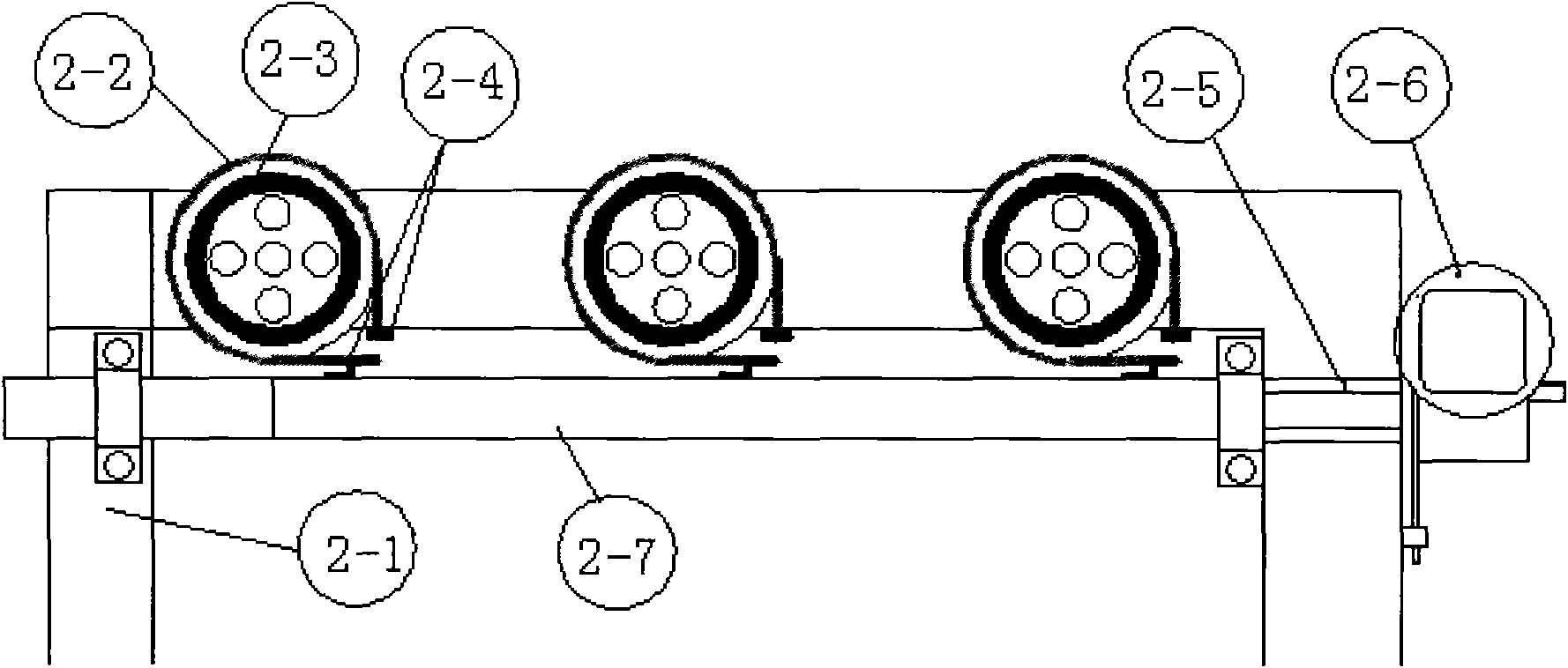

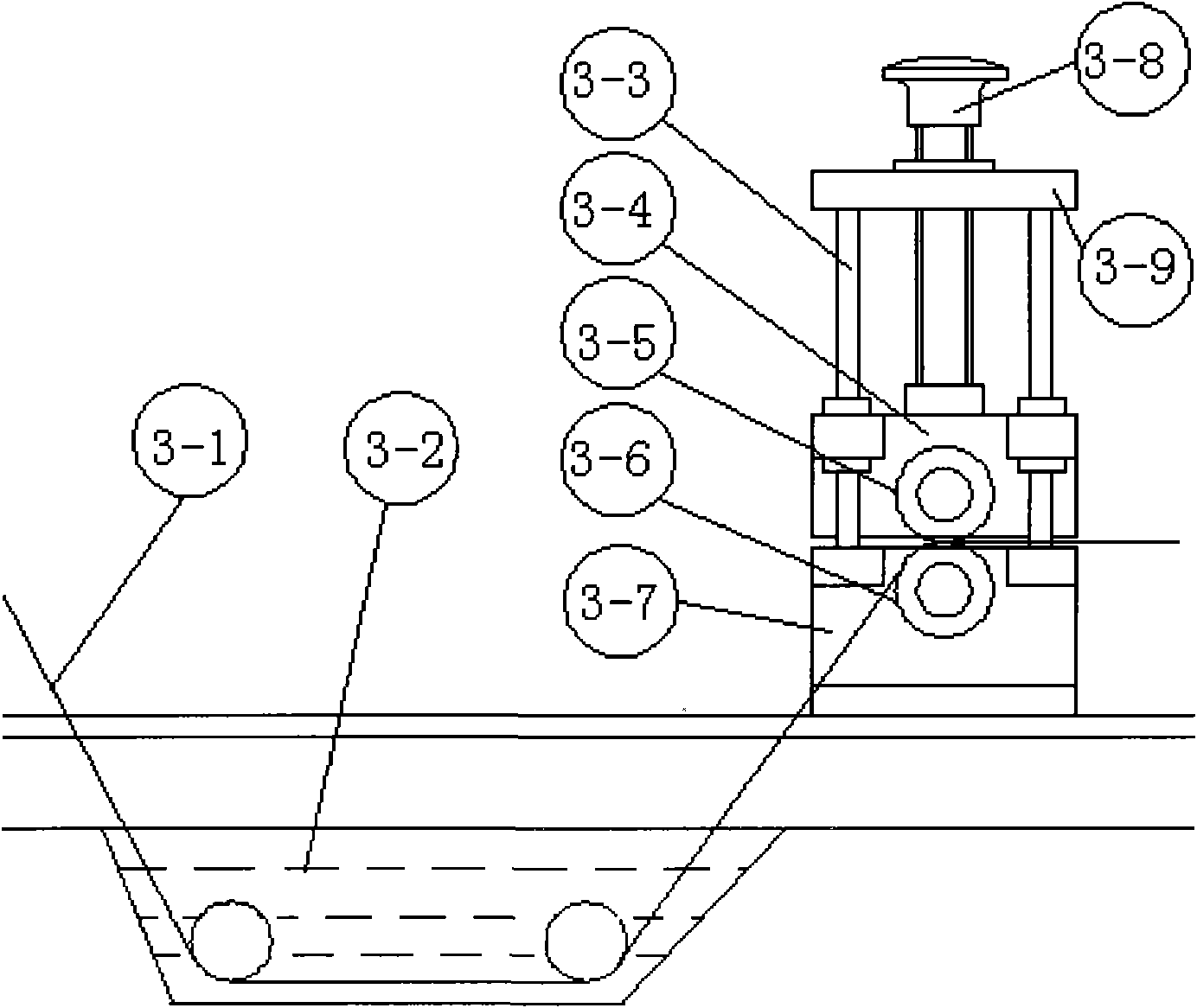

[0014] Such as figure 1 Firstly, according to different composite material matrices and their applications, reasonably prepare the matrix glue, put it into the glue groove (1-5) on the path where the fiber passes, and place the glue groove behind the tension sensor. The multi-filament fiber bobbin (1-3) is fixed on the rotating movable support, and the bobbin is fixed by apron friction. The tension of the multi-filament yarn is adjusted by the coaxial tension tension adjustment method, and the servo motor is used to adjust the tension. Drive the coaxial adjustment of the worm gear and worm, and the servo motor drives the connecting rod (1-2) through the worm gear reducer to synchronously move the friction brake mechanisms of the three bobbins at the same time, so as to achieve the effect of simultaneously adjusting the tension. The fiber tow passes through three tension rollers (1-4) and dipped in the glue tank. The tension sensor is placed before the glue tank, which not only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com