High-speed railway noise barrier

A high-speed railway and sound barrier technology, applied in the field of components, can solve the problems of single design form and poor durability, and achieve the effects of noise reduction, good fatigue resistance, and convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

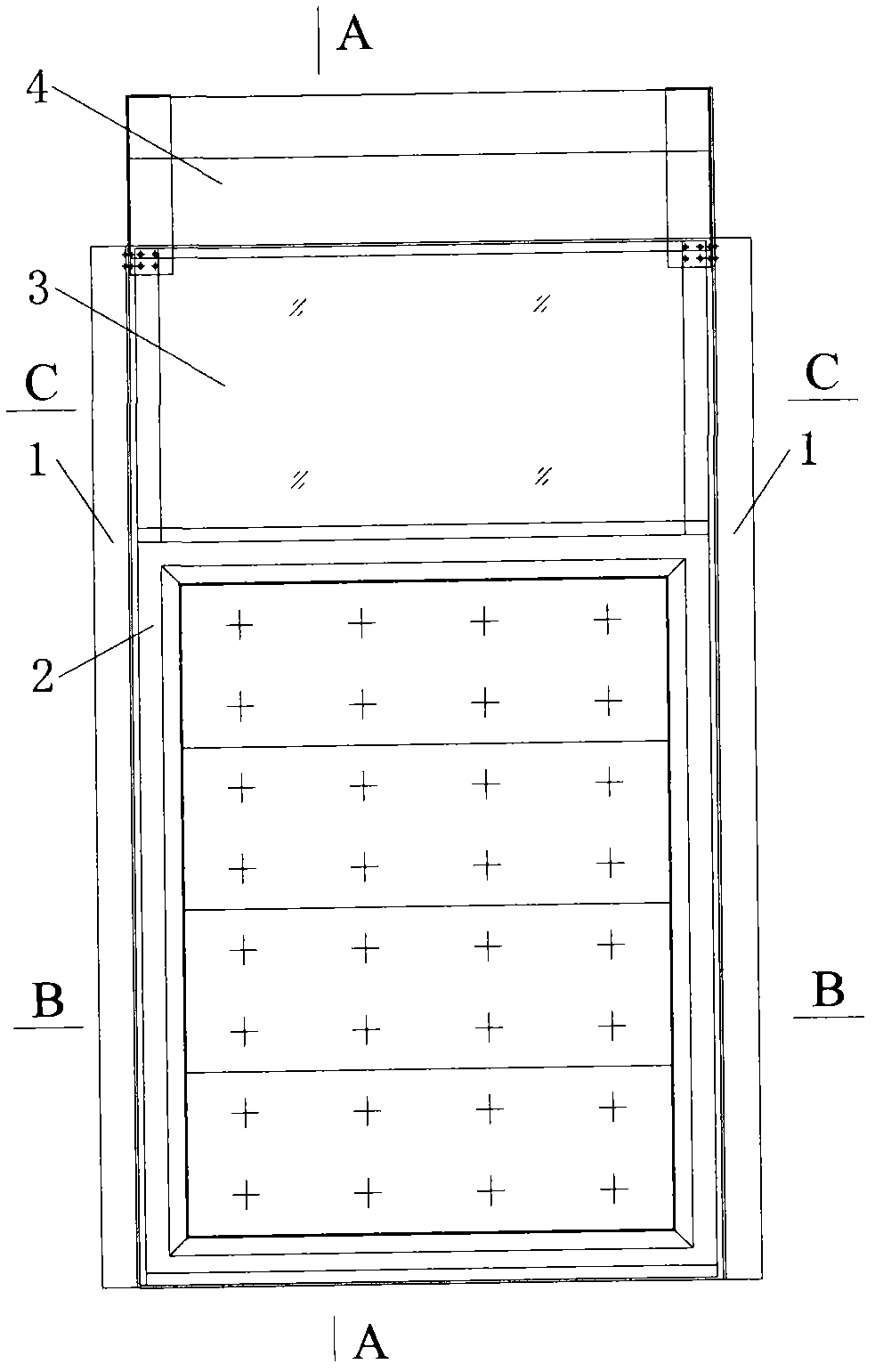

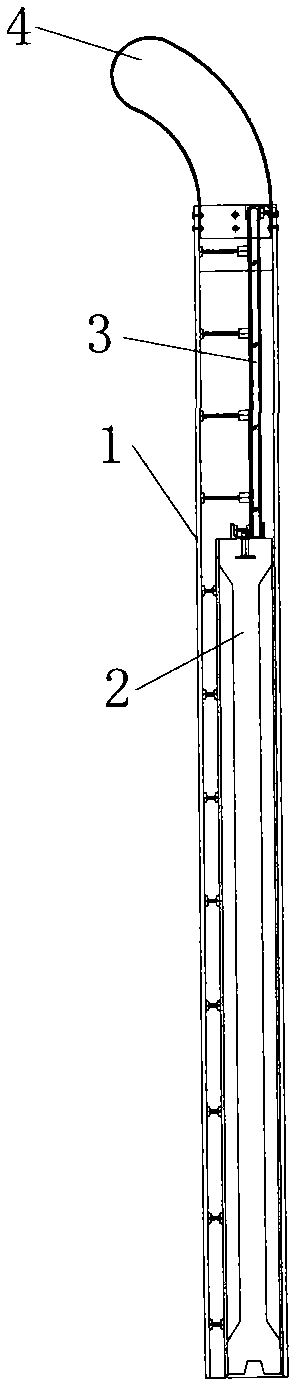

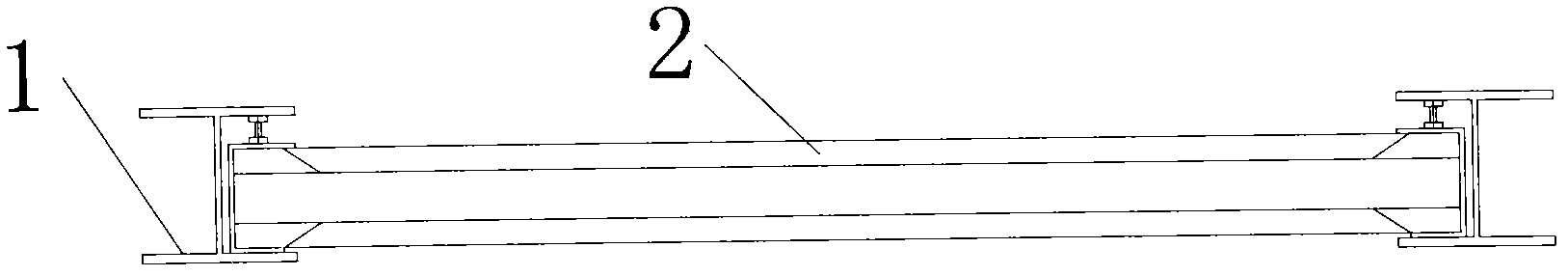

[0038] Such as figure 1 As shown, the high-speed railway sound barrier includes an H-shaped steel metal column 1, a prefabricated concrete sound-absorbing panel 2 inserted into the H-shaped steel metal column 1, and a transparent sound-insulating panel 3 is installed on the top of the pre-fabricated concrete sound-absorbing panel 2. The top is provided with a curved sound-absorbing top 4.

[0039] The precast concrete sound-absorbing panel 2 is assembled by connecting the precast concrete insert 21 and the sound-absorbing panel 22 through bolts 23; in order to solve the problem of connection and sound insulation at the bottom of the precast concrete insert 21, a groove is provided at the bottom of the precast concrete insert 21 24, and cooperate with the convex rubber pad 7 to realize the flexible connection between the bottom of the prefabricated concrete insert 21 and the concrete longitudinal beam and achieve the effect of sound decoupling; at the same time, the grooved rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com