Clutch electric control mechanism for vehicle

A control mechanism and clutch technology, applied to clutches, mechanical equipment, vehicle components, etc., can solve problems such as low transmission efficiency and large drive motor power, reduce motor power, reduce power and volume, and facilitate vehicle integration and installation and layout effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

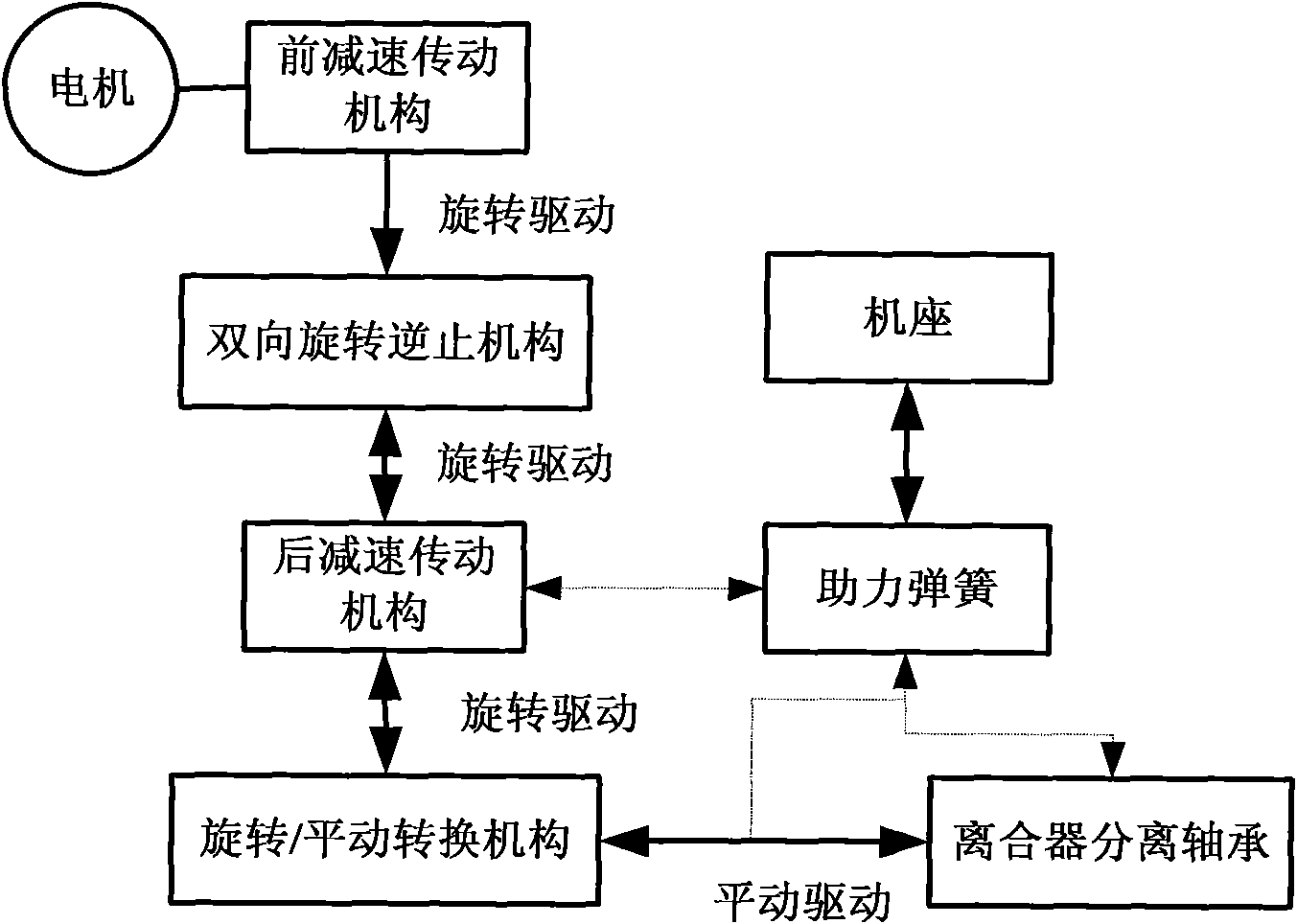

[0018] A vehicle clutch electric control mechanism, its working principle is as follows: figure 1 As shown, the mechanism includes a drive motor, a two-way rotation backstop mechanism, a front deceleration transmission mechanism, a rear deceleration transmission mechanism and a rotation / translation conversion mechanism. The drive motor is connected to the two-way rotation backstop mechanism through the front deceleration transmission mechanism. The transmission mechanism adopts a fixed-axis structure, and the rotation / translation conversion mechanism and the bidirectional rotation check mechanism are connected through a rear reduction transmission mechanism. The rear reduction transmission mechanism adopts a planetary gear structure, and the rotation / translation conversion mechanism adopts a ball screw structure. The translation conversion mechanism also separates the clutch through the clutch release bearing, and a one-way booster spring is also arranged between the two-way ro...

Embodiment 2

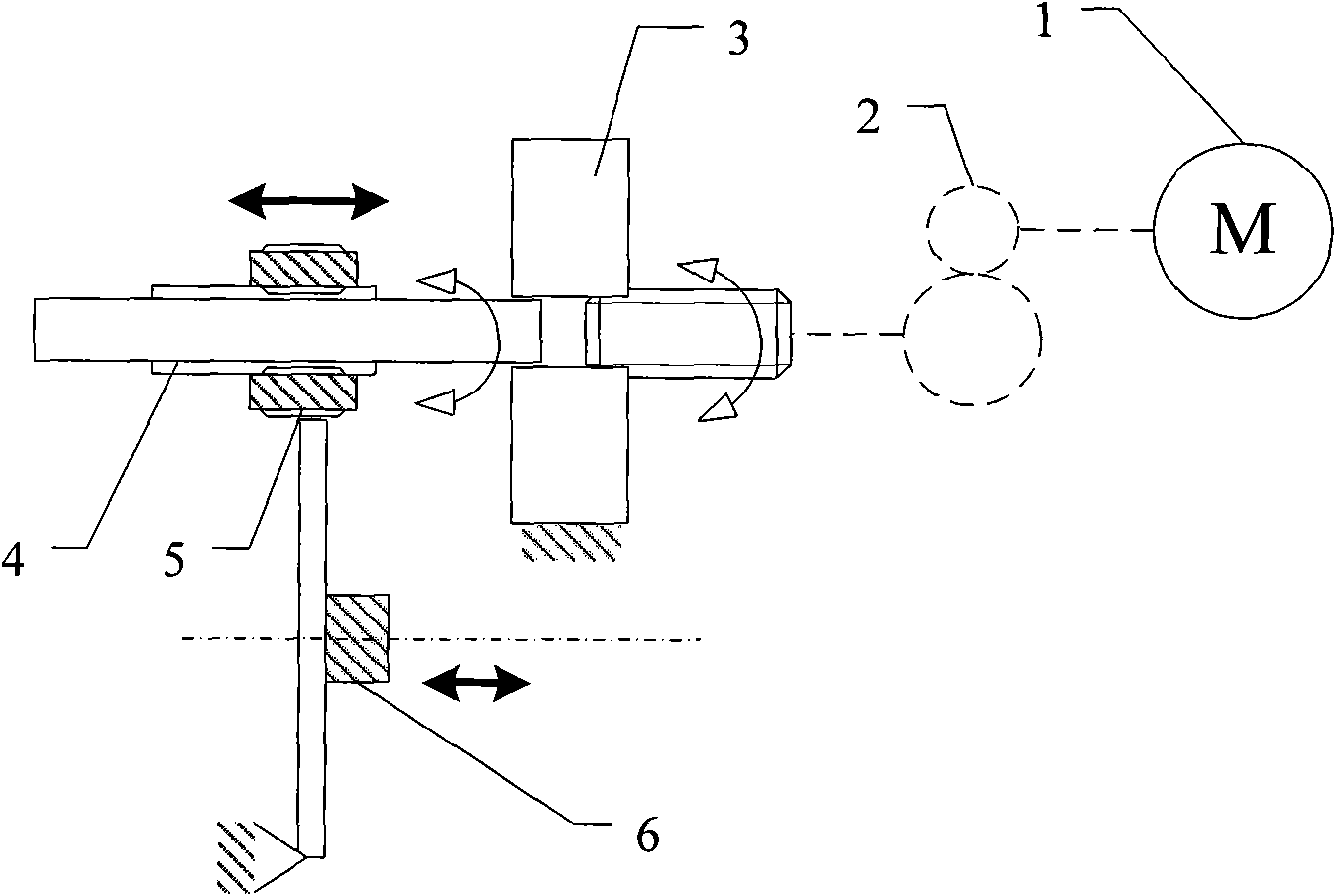

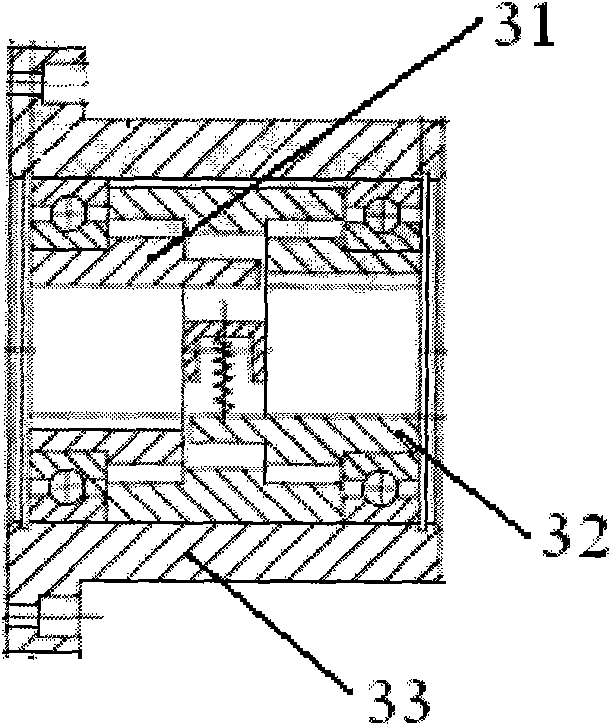

[0021] A high-efficiency vehicle clutch electric control mechanism, the specific structure is as follows figure 2 As shown, it includes a driving motor 1, a gear meshing pair 2, a two-way sprag overrunning clutch 3, a ball screw 4, a ball screw nut 5, and a clutch release bearing 6. The rotor of the drive motor 1 drives the driving gear connected to the gear meshing pair 2, and the driven gear of the gear meshing pair 2 is connected to the input shaft drive 31 of the two-way wedge overrunning clutch 3, and the gear meshing pair 2 can be configured as a multi-stage fixed shaft as required Common forms such as gear reduction or planetary gear reduction; the output shaft of the two-way sprag overrunning clutch 3 drives 32 to connect the lead screw 4 of the ball screw, thereby converting the rotational motion into the translational motion of the nut 5, and the nut 5 further translates to drive the clutch The release bearing 6 realizes the separation and combination of the clutch....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com