Optical fiber and method of manufacturing the same

A technology of optical fiber and fiber core, applied in the optical fiber field of submarine optical cable, can solve the problem of reducing the replacement cost of seawater intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

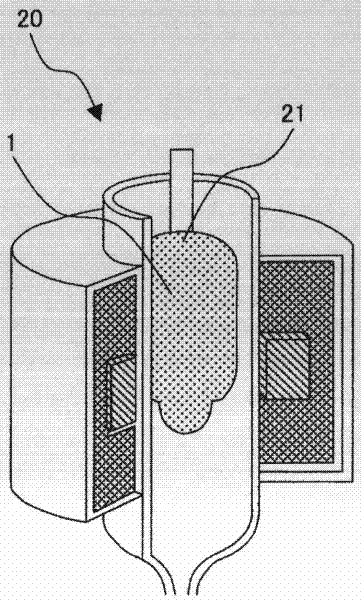

[0025] Preferred embodiments of the present invention will be described with reference to the drawings.

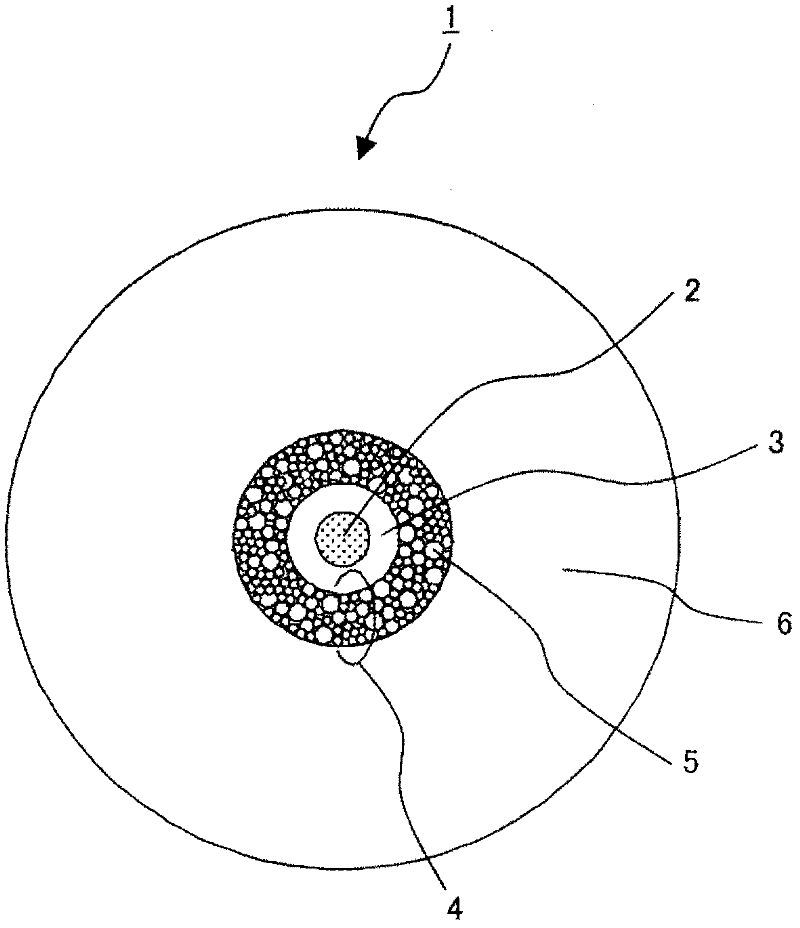

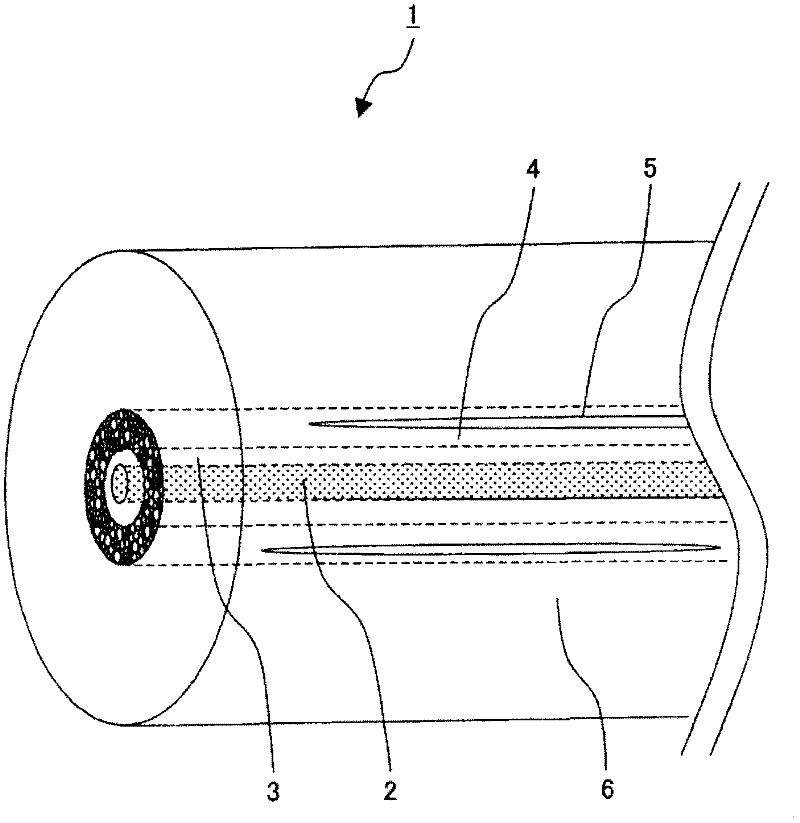

[0026] figure 1 It is a cross-sectional view in the direction of the central axis of the optical fiber according to a preferred embodiment of the present invention. figure 2 It is a side cross-sectional view of an optical fiber 1 according to a preferred embodiment of the present invention.

[0027] A suitable embodiment of the present invention is an optical fiber 1, which is an optical fiber 1 for a submarine optical cable, and is characterized in that it has a core 2 disposed in the central axis region, is disposed on the outer periphery of the core 2, and has a An inner cladding 3 with a small refractive index is provided on the outer periphery of the inner cladding 3, and a bubble layer 4 having a plurality of long-hole-shaped bubbles 5 is provided on the outer periphery of the bubble layer 4, and has a The core 2 has an outer cladding 6 having a refractive index e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com