Method and device for designing three-dimensional closed guide blade with tubular type conical space

A space guide vane and tubular flow technology, applied in the field of hydraulic machinery, can solve the problems of flow performance influence, mutual interference of geometric shapes, difficult to control and ensure the flow performance of guide vanes, etc., and achieve good hydraulic performance and small flow loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

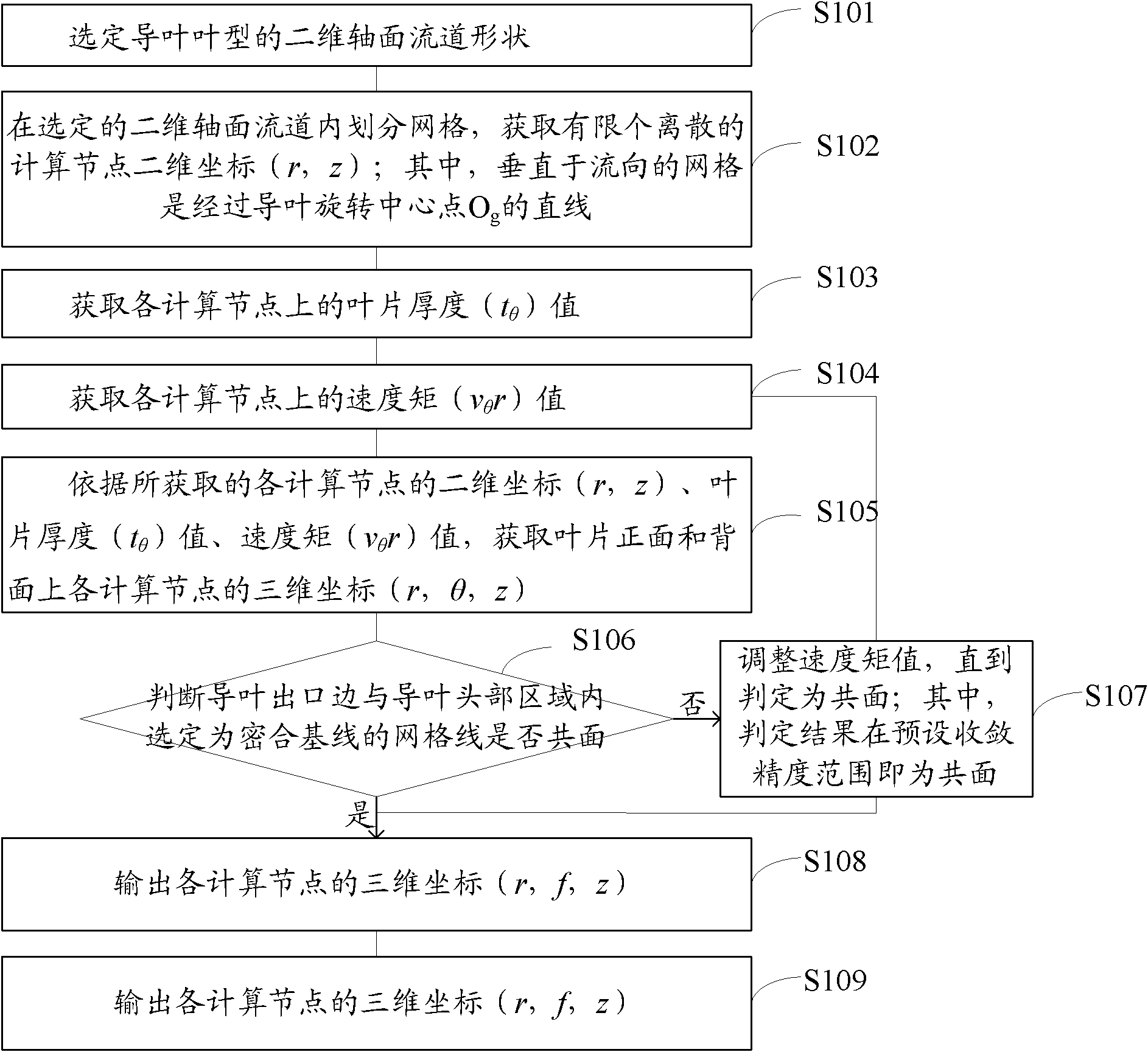

[0058] refer to figure 1 , which shows a flow chart of a three-dimensional close-fit design method for through-flow conical space guide vanes of the present invention, the method specifically includes:

[0059] Step S101, selecting the two-dimensional axial flow channel shape of the guide vane type;

[0060]Preferably, the two-dimensional axial flow channel shape of the selected guide vane type includes the following sub-steps:

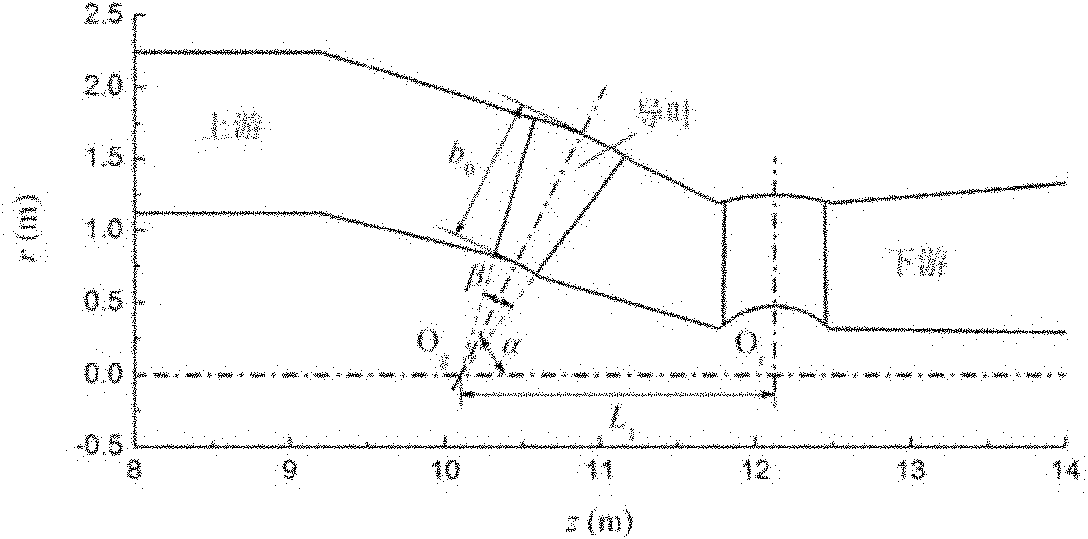

[0061] Determine the guide vane rotation center point O g ;

[0062] Determine the blade rotation center point O r ;

[0063] Determine guide vane height b 0 ;

[0064] Determine the inclination angle α between the rotation axis of the guide vane and the rotation axis of the runner;

[0065] Determine the axial angle β between the inlet side and the outlet side.

[0066] Preferably, the outlet side is selected to pass through the guide vane rotation center O g point line.

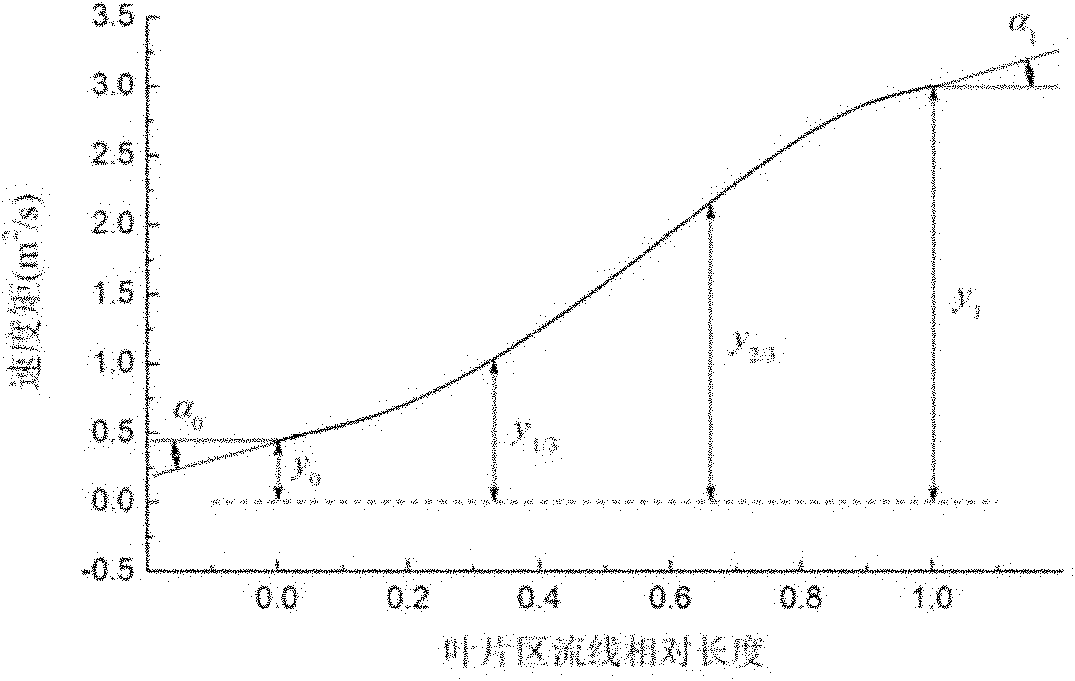

[0067] According to the hydraulic parameters and size of the unit, s...

Embodiment 2

[0133] refer to Figure 9 , which shows a structural diagram of a three-dimensional close-fit design device for through-flow conical space guide vanes of the present invention, the device specifically includes:

[0134] The first selection module 901 is used to select the shape of the two-dimensional axial flow channel of the guide vane type;

[0135] Preferably, the first selection module 901 specifically includes the following submodules:

[0136] The first determination sub-module 9011 is used to determine the rotation center point O of the guide vane g ;

[0137] The second determination sub-module 9012 is used to determine the blade rotation center point O r ;

[0138] The third determination sub-module 9013 is used to determine the guide vane height b 0 ;

[0139] The fourth determination sub-module 9014 is used to determine the inclination α between the rotation axis of the guide vane and the rotation axis of the runner;

[0140] The fifth determination sub-modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com