Deep hole type water cooling loop device for baseplate of electric cabinet

A technology of water cooling and electric control box, which is applied in the direction of cooling/ventilation, cooling/ventilation/heating transformation of substation/switchgear, etc. It can solve the problems of long processing time, increased production process and cost, and many times of secondary welding, etc. , to achieve the effect of reducing manufacturing cost and cycle, saving welding stress process, and reducing metal cutting amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

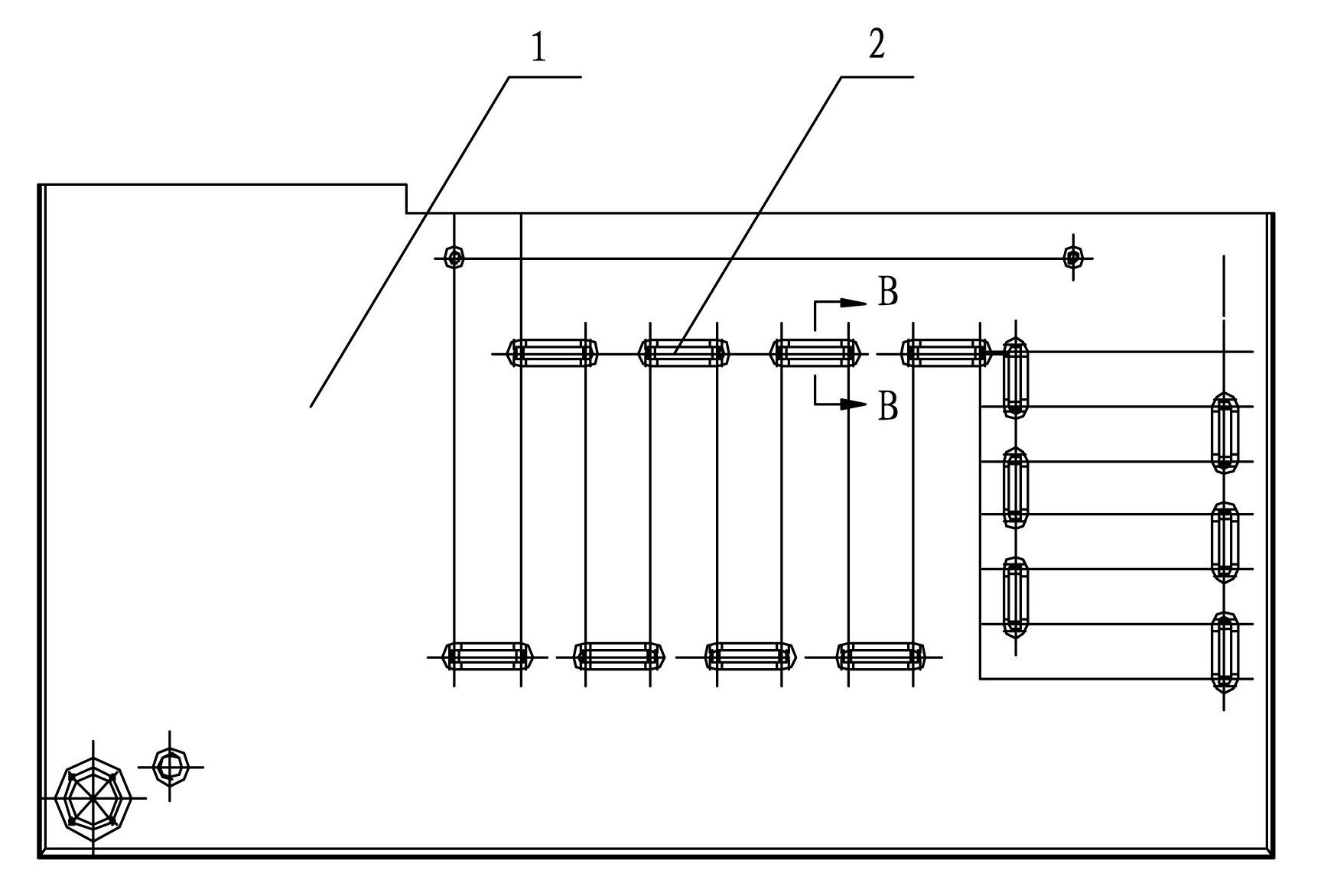

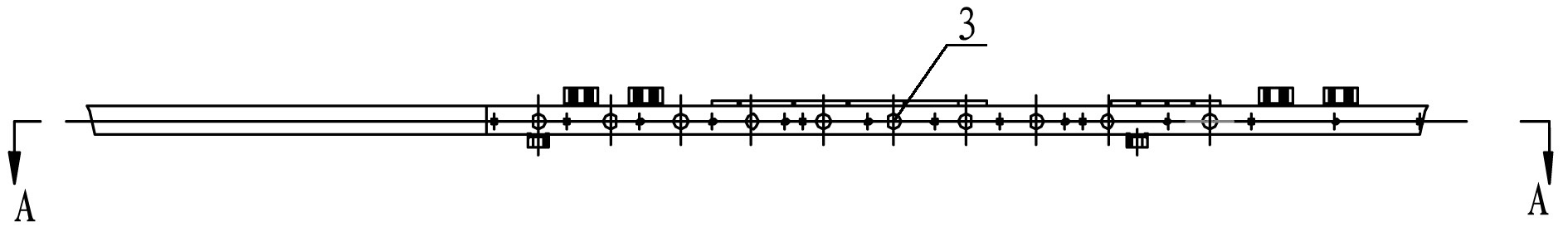

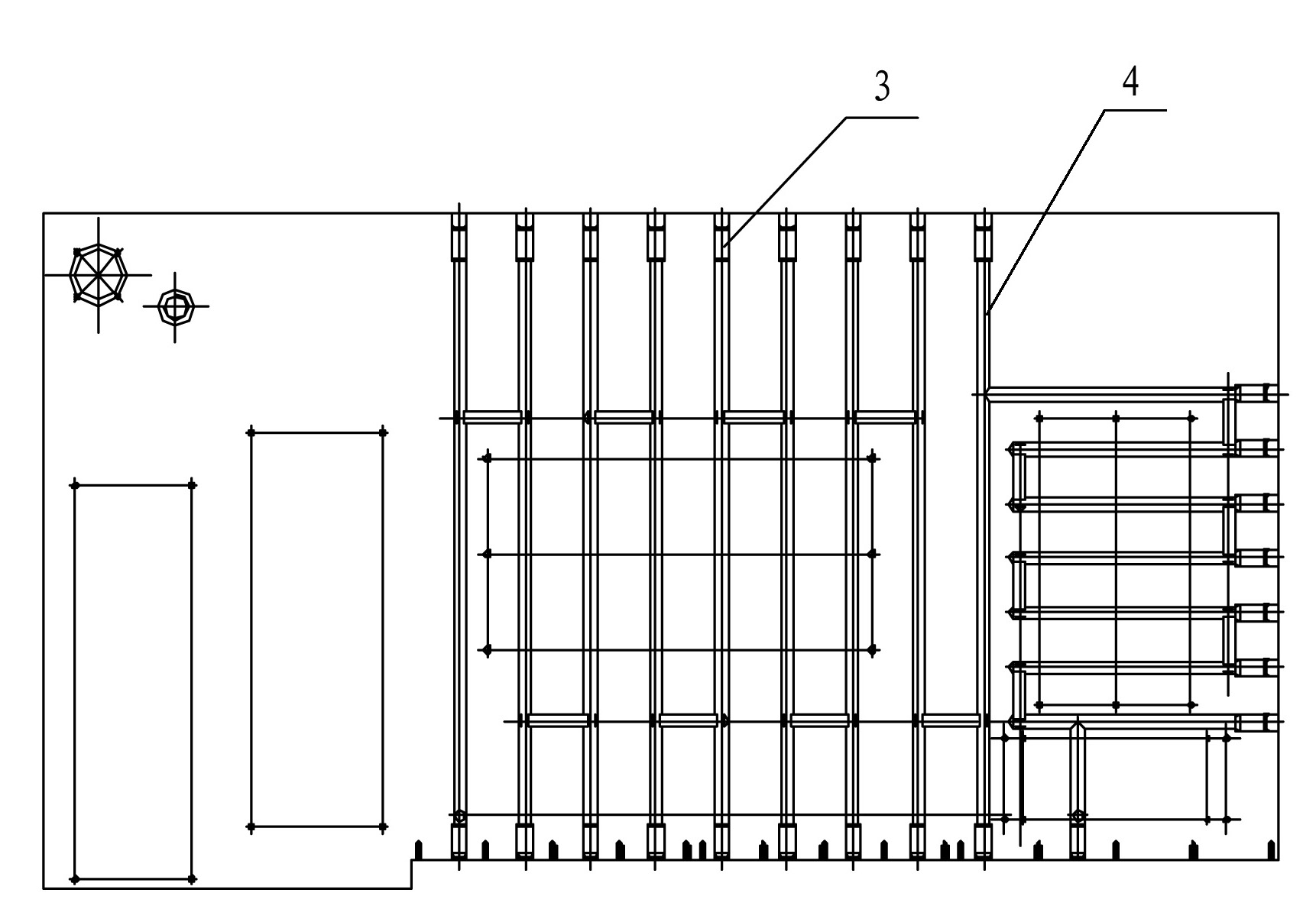

[0015] Several rows of deep holes are drilled on the thickness of the bottom plate 1 as the main cooling water channel 4. The axis of the deep holes is parallel to the bottom plate surface. The pin plug 3 is welded to the opening of the deep hole and sealed. The connecting water channels 2 are spaced apart to connect two adjacent rows of deep holes. One of the adjacent connecting water channels is at the upper end of the deep holes and the other is at the lower end of the deep holes. All the cooling main water channels 4 are connected into pulse waveform cooling water channels. See Figure 4 , the method for processing the connected water channel is to open a cross-section on the base plate to be an inverted convex groove, and cover plate 5 is embedded in the upper groove and fixed by welding, and the lower groove forms the connected water channel 2. Before use, carry out a pressure test on the waterway circuit, the pressure is 3MPa, keep the pressure for 10 minutes, and there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com