Optical fiber cable and optical fiber tape

一种光纤缆线、光纤带的技术,应用在光纤带以及光纤缆线领域,能够解决光纤大形变及光损失等问题,达到经济性优良、取出性优良、充分长期可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

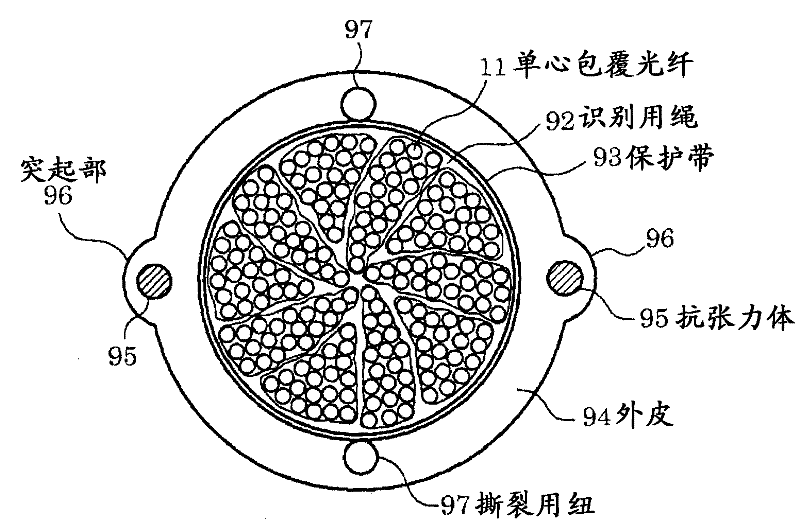

[0062] figure 1 It is a cross-sectional view showing an optical fiber cable according to an embodiment of the present invention. in figure 1 Among them, 11 is a single-core coated optical fiber, 92 is an identification cord, 93 is a protective tape, 94 is a sheath, 95 is a tension member, 96 is a protrusion, and 97 is a tear button.

[0063] Such as figure 1 As shown, a unit is formed by winding the identification cord 92 on the outer circumference of an optical fiber bundle obtained by gathering a plurality of, for example, 20 single-core coated optical fibers 11 with a diameter of 0.25 mm denser than straight. A plurality of, for example, 10 of the units are twisted in one direction to form a densely packed outer periphery, and a rolled layer composed of a plurality of thinner protective tapes 93 is provided, and an outer skin 94 is added to the outer periphery to form a density Very high 200-core multi-core fiber optic cable. The unit is configured using an optical fiber ribb...

Embodiment approach 2

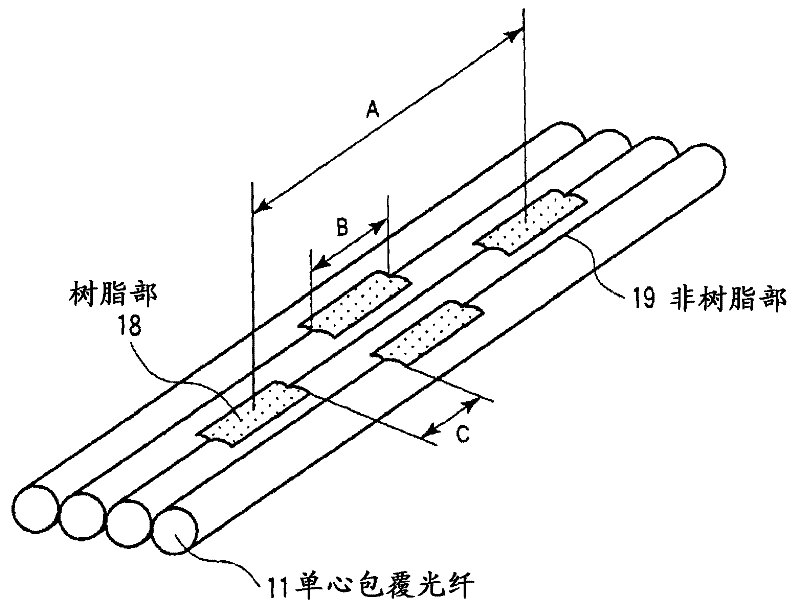

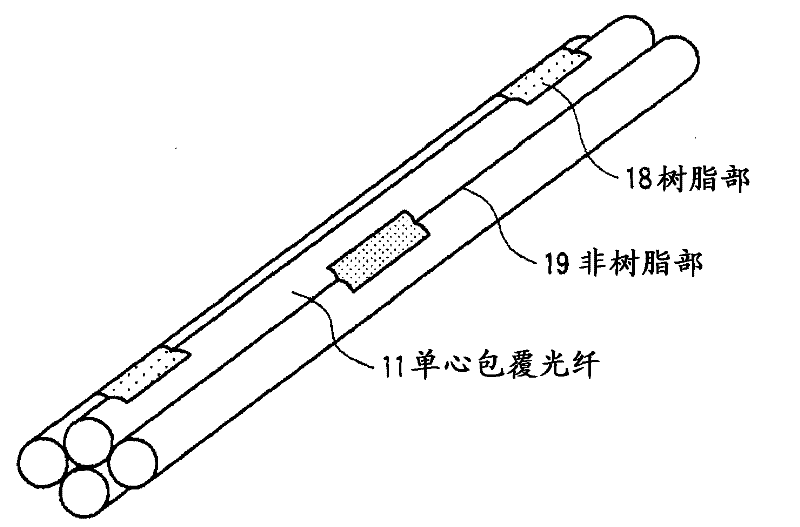

[0112] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Figure 8 (a) is a cross-sectional view showing an example of the optical fiber ribbon of the first embodiment of the present invention, Figure 8 (b) is a cross-sectional view showing another example of the optical fiber ribbon of the first embodiment of the present invention. in Figure 8 In (a), 11, 12, 13, 14 are single-core coated optical fibers, and 15, 16, 17 are connecting portions.

[0113] Such as Figure 8 As shown in (a), a plurality of (n) such as n=4 single-core coated optical fibers 11, 12, 13, and 14 with an outer diameter d (μm) are arranged, and each single-core coated optical fiber 11, 12, 13, and 14 are arranged so as to be separated from each other without touching each other, and the adjacent single-core coated optical fibers 11, 12, 13, 14 are continuously connected in the longitudinal direction through n-1, that is, three connecting portions ...

Embodiment approach 3

[0157] figure 1 , Figure 13 The optical fiber cable described in the above further includes a lateral pressure protection layer made of a metal tube 99 on the outer periphery of the outer sheath 94. The metal pipe 99 can be provided as a corrugated pipe that has been corrugated. Figure 15 Is explained in figure 1 The optical fiber cable described in is a diagram showing a case where a metal tube 99 is provided. Figure 16 Is explained in Figure 13 The optical fiber cable described in is a diagram showing a case where a metal tube 99 is provided. in Figure 15 , Figure 16 In the optical fiber cable, since the metal tube 99 serves as a protection against the cable side pressure, it does not need to be laid in the pipeline and can be directly buried underground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com