Automatic welding device

A technology of automatic welding and welding machinery, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, complicated program control, unsuitable welding of support beam structure, etc. Labor Intensity and Welding Occupational Hazards, Effect of Improving Product Profit Rate and Product Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, the integrated pipe bending device of the present invention will be described in detail with reference to the accompanying drawings and embodiments:

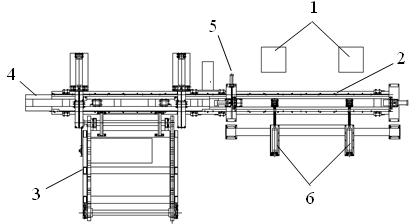

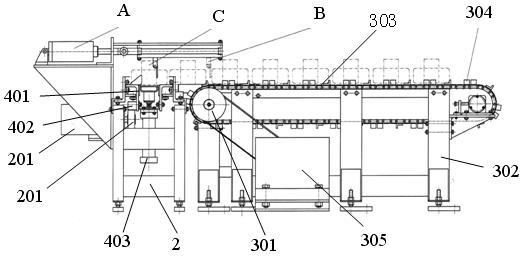

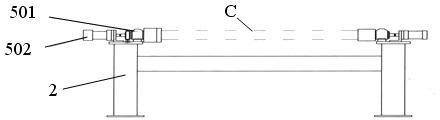

[0031] figure 1 is the top view of the automatic welding device of the present invention; figure 2 is a partial side view of the automatic welding device of the present invention; image 3 is the schematic diagram of the clamping device of the automatic welding device of the present invention; Figure 4 It is a schematic diagram of the turning device and the unloading device of the automatic welding device of the present invention.

[0032] like figure 1 As shown, an automatic welding device of the present invention includes a welding machine 1; a control device (not shown) for controlling the welding machine 1; a bracket 2 forming an overall structural frame; and a feeding device 3 arranged at one end of the outer side of the bracket; A pallet device 4 arranged in the raceway groove of the bracket; a clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com