Rail-type dismounting equipment of polypropylene fiber high-pressure spinning component

A high-pressure spinning, rail-type technology, applied in the field of rail-type disassembly and assembly devices, can solve the problems of unsafe, unsafe, height difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

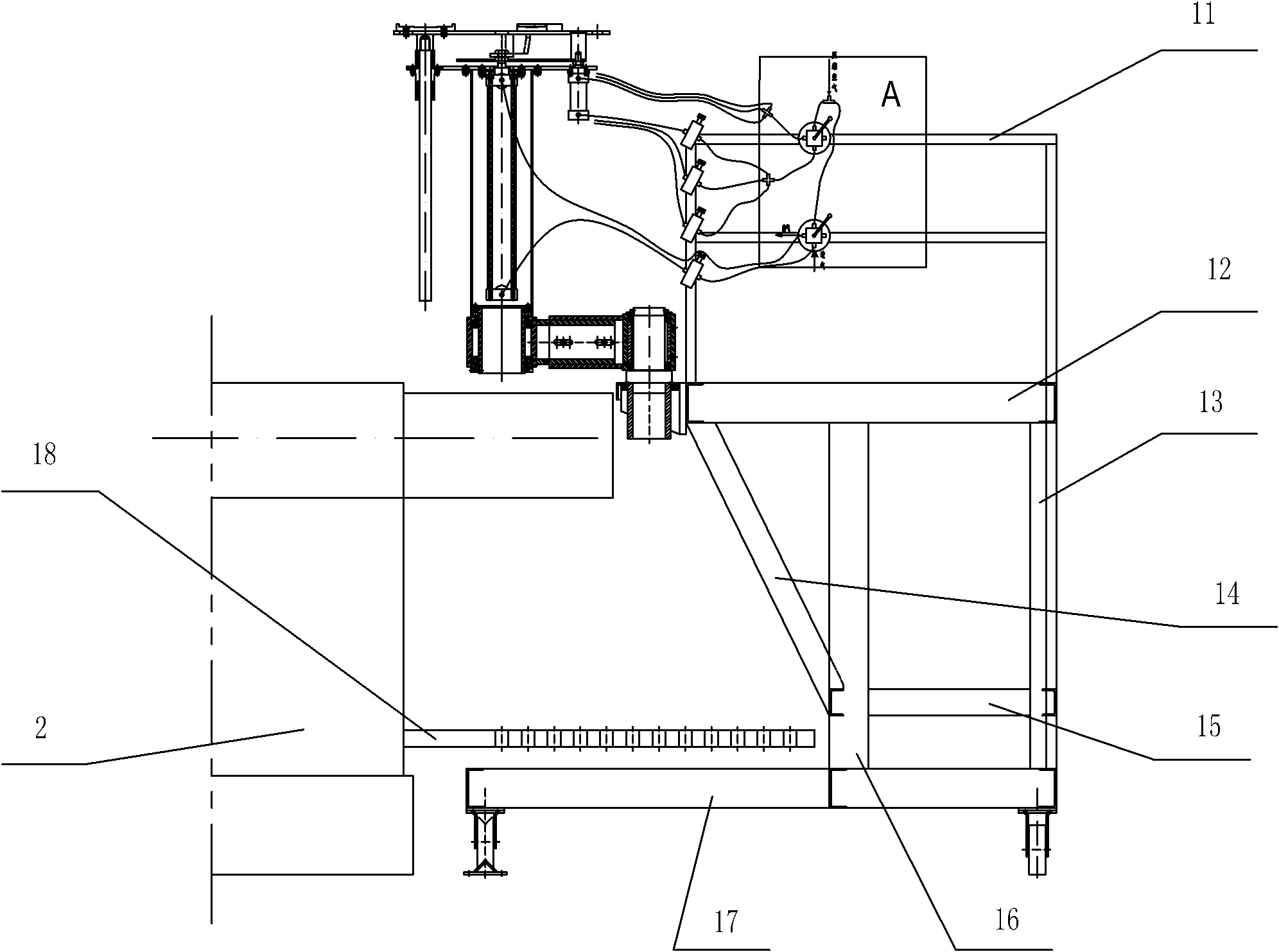

[0027] The accompanying drawings disclose non-restrictive structural schematic diagrams of preferred embodiments involved in the present invention, and the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

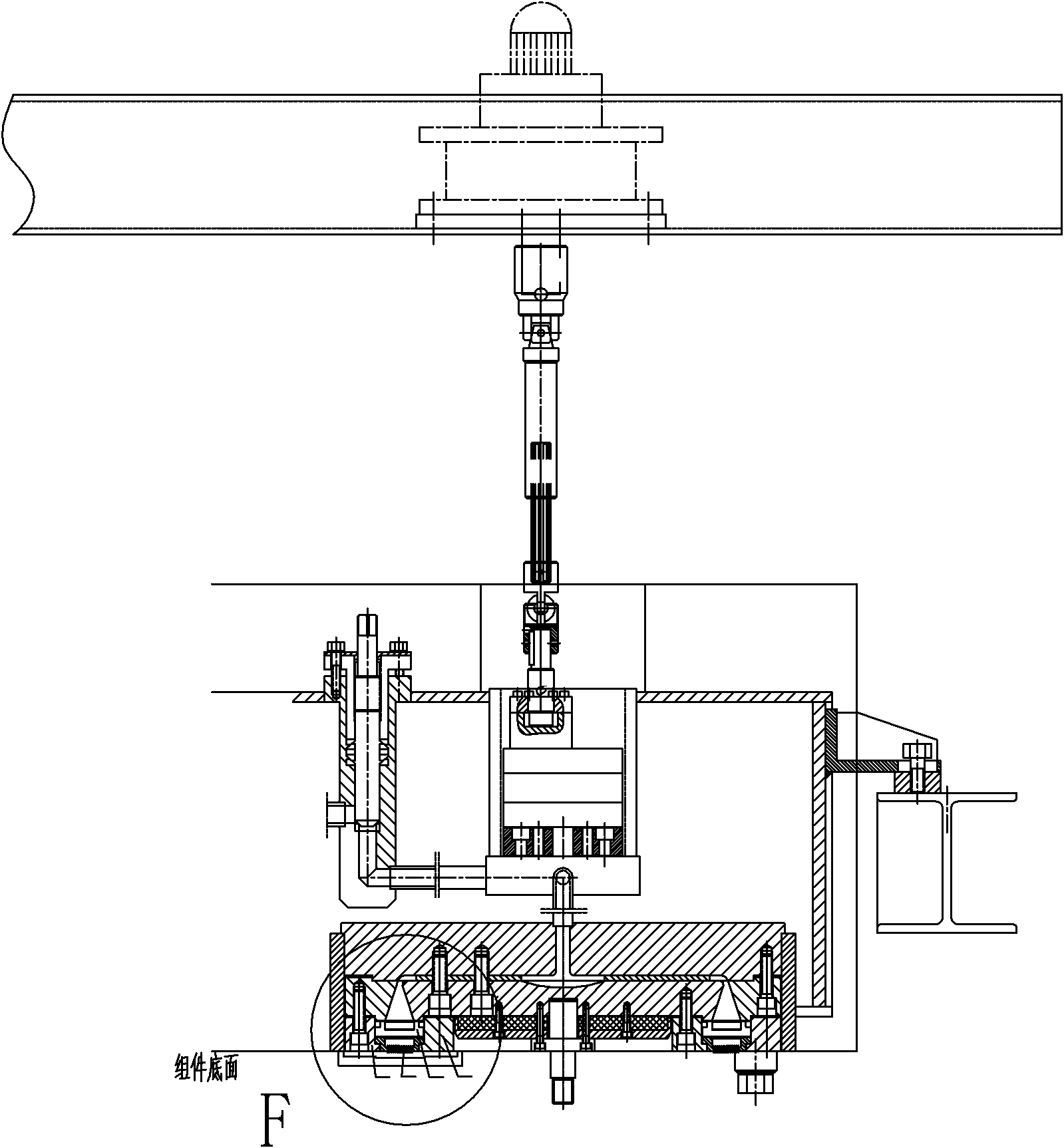

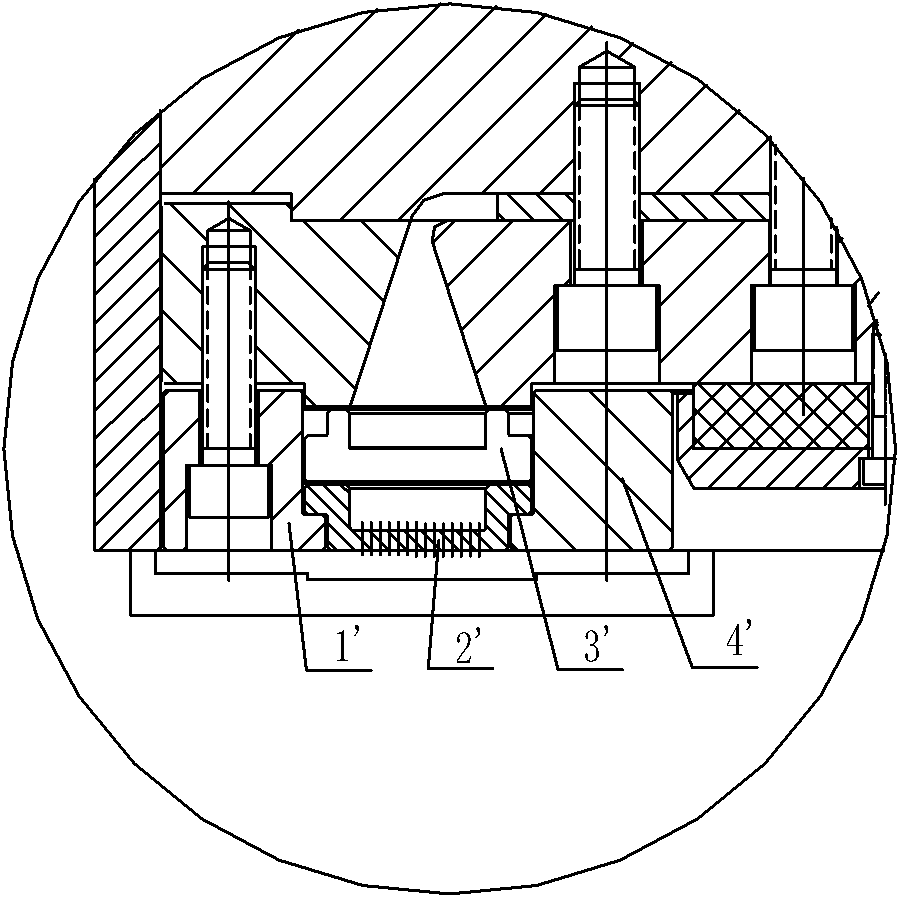

[0028] Such as Figures 3 to 8 As shown, the orbital dismounting device of the propylene fiber tow high-pressure spinning assembly of the present invention includes a frame, an orbital moving mechanism, a rocker arm rotating mechanism, a tray lifting and rotating separation mechanism, and a tray 5, wherein:

[0029] The rack, such as image 3 Shown, be made of guardrail 11, upper beam 12, side column 13, diagonal brace beam 14, center beam 15, center column 16, bottom beam 17, center column 16 and side column 13 are located on bottom beam 17 and support jointly.

[0030] The orbital moving mechanism, such as Figure 6 As shown, it includes a plane track, a backing plate 61, a wheel frame 62, a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com