Laminating method of liquid optical cement laminating machine

A technology of optical glue and laminating machine, which is applied in the direction of chemical instruments and methods, static indicators, lamination devices, etc., can solve the problems of poor utilization of factory space and occupancy, and achieve simple and easy monitoring and management, reducing space, The effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical means adopted by the present invention in order to realize the intended invention purpose will be further elaborated below with reference to the accompanying drawings and preferred embodiments of the present invention.

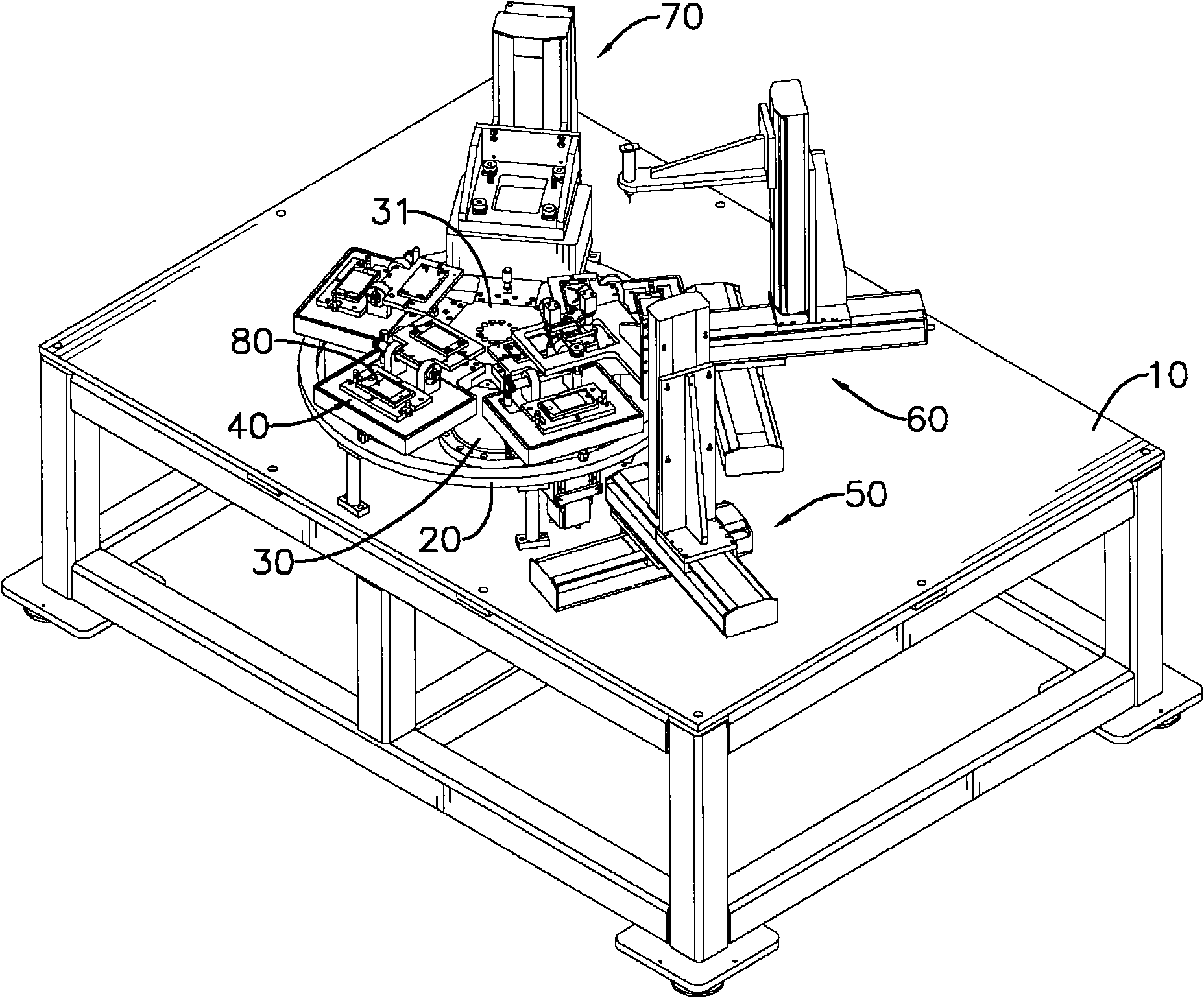

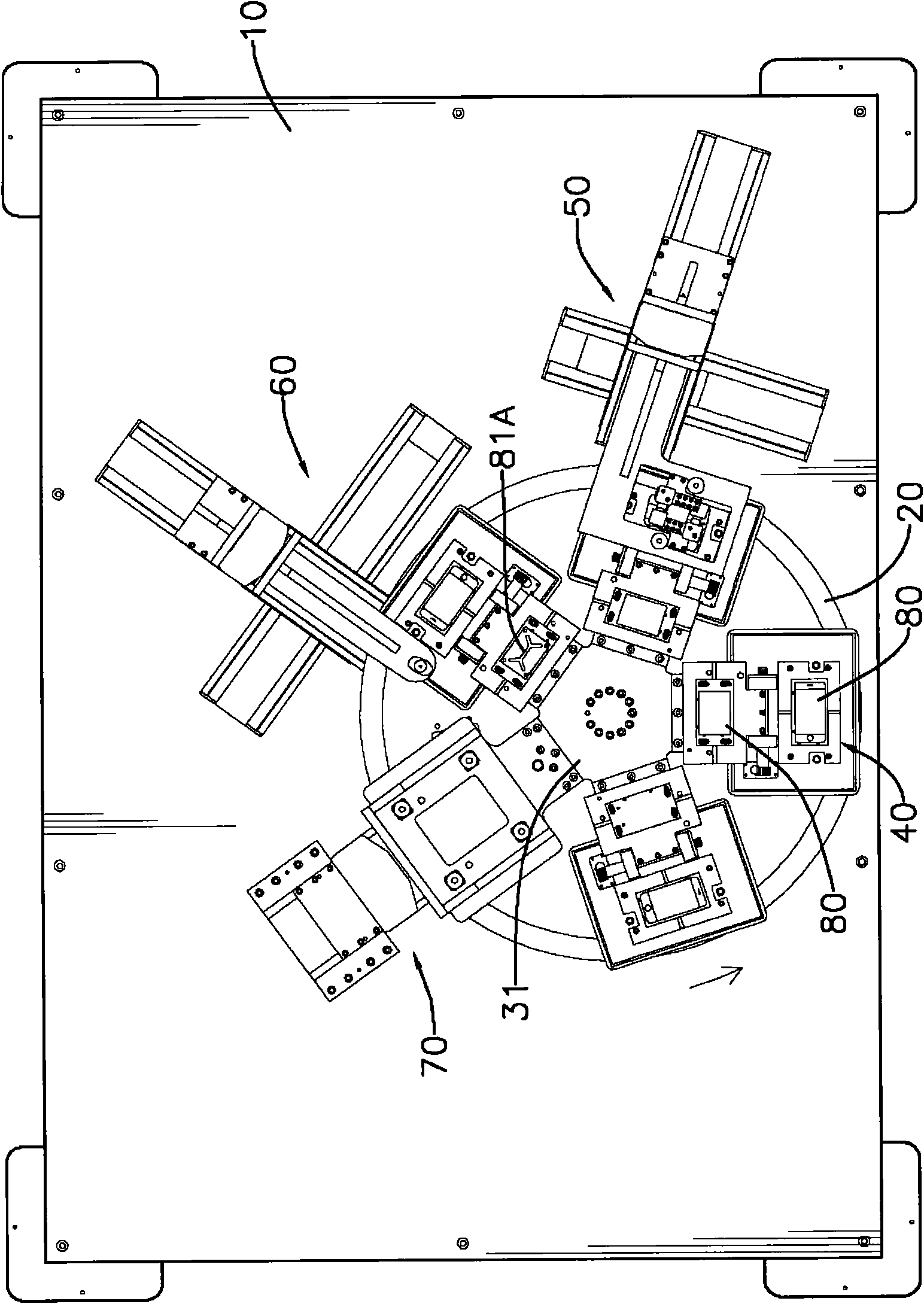

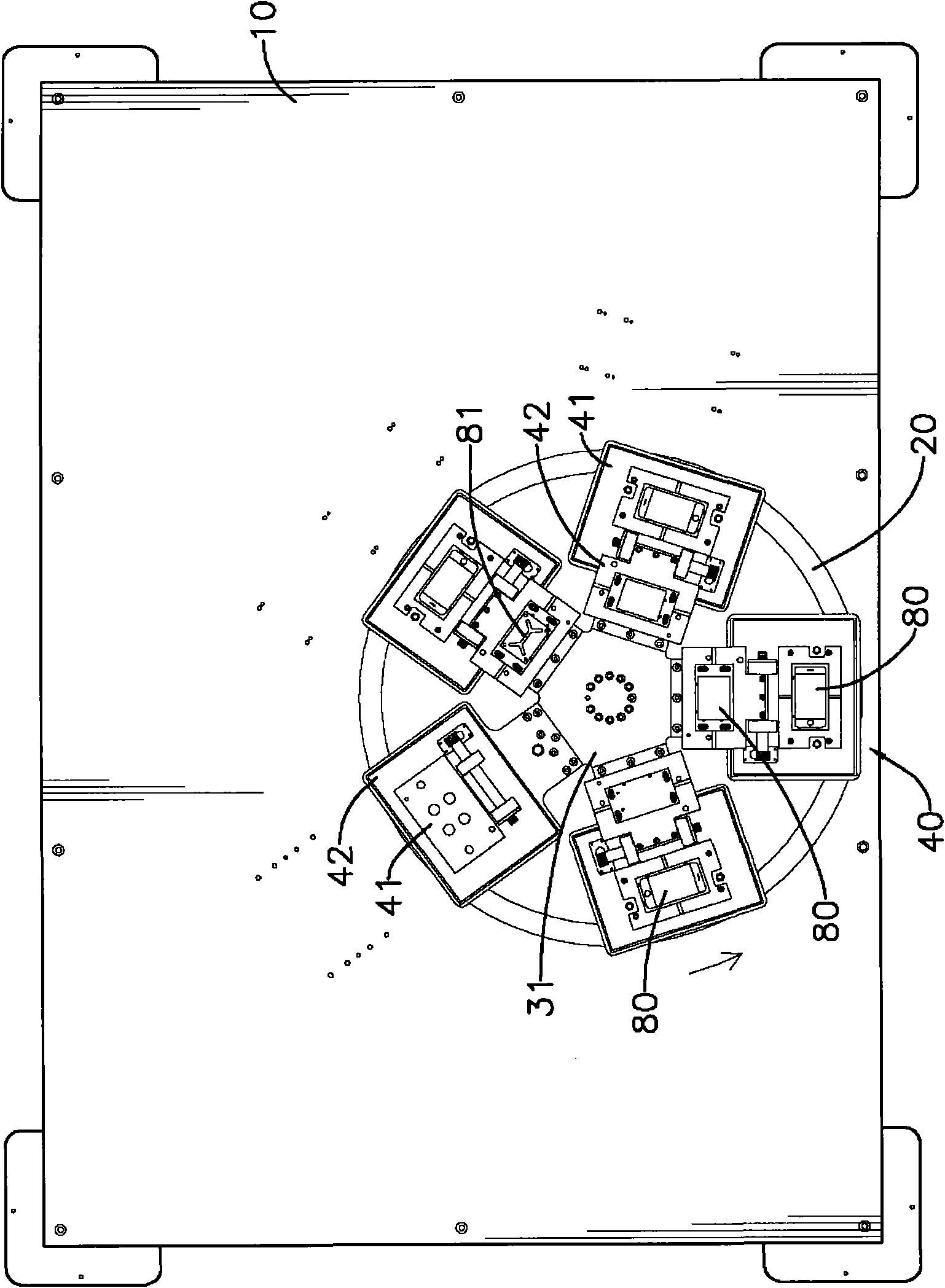

[0043] Figure 1 to Figure 3 It represents a specific embodiment in which the laminating method of the present invention is applied to a liquid optical glue laminating machine, wherein the laminating machine has a machine table (10), a fixed frame (20), a rotary drive device (30), a plurality of carrying device (40), detection device (50), dispensing device (60) and vacuum pressing device (70), the fixed frame (20) is a hollow ring frame body, and is fixed on the machine platform (10) , the rotary driving device (30) is assembled on the machine platform (10), and is located inside the hollow frame body of the fixed frame (20), and the top of the rotary driving device (30) is provided with a rotary platform (31 ), the carrying device (40) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com