Anti-noise plate supplying device of automobile brake block

A technology for supplying equipment and automobile brakes, which is applied in the direction of mechanical equipment, friction linings, gear transmission mechanisms, etc., can solve the problems of inability to realize automation of accessory assembly equipment, lower production efficiency, and supply of anti-noise panels, so as to avoid product defects Phenomenon, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

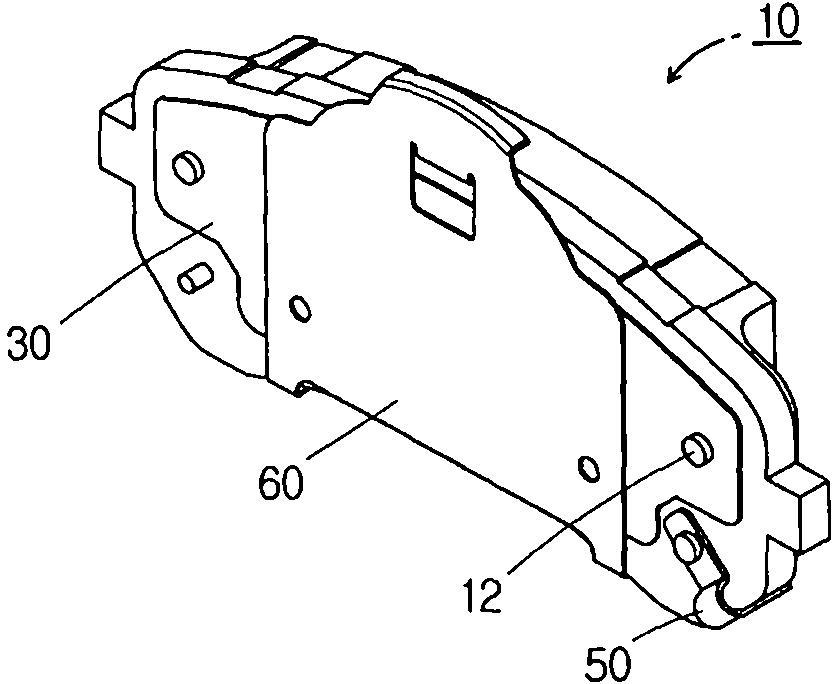

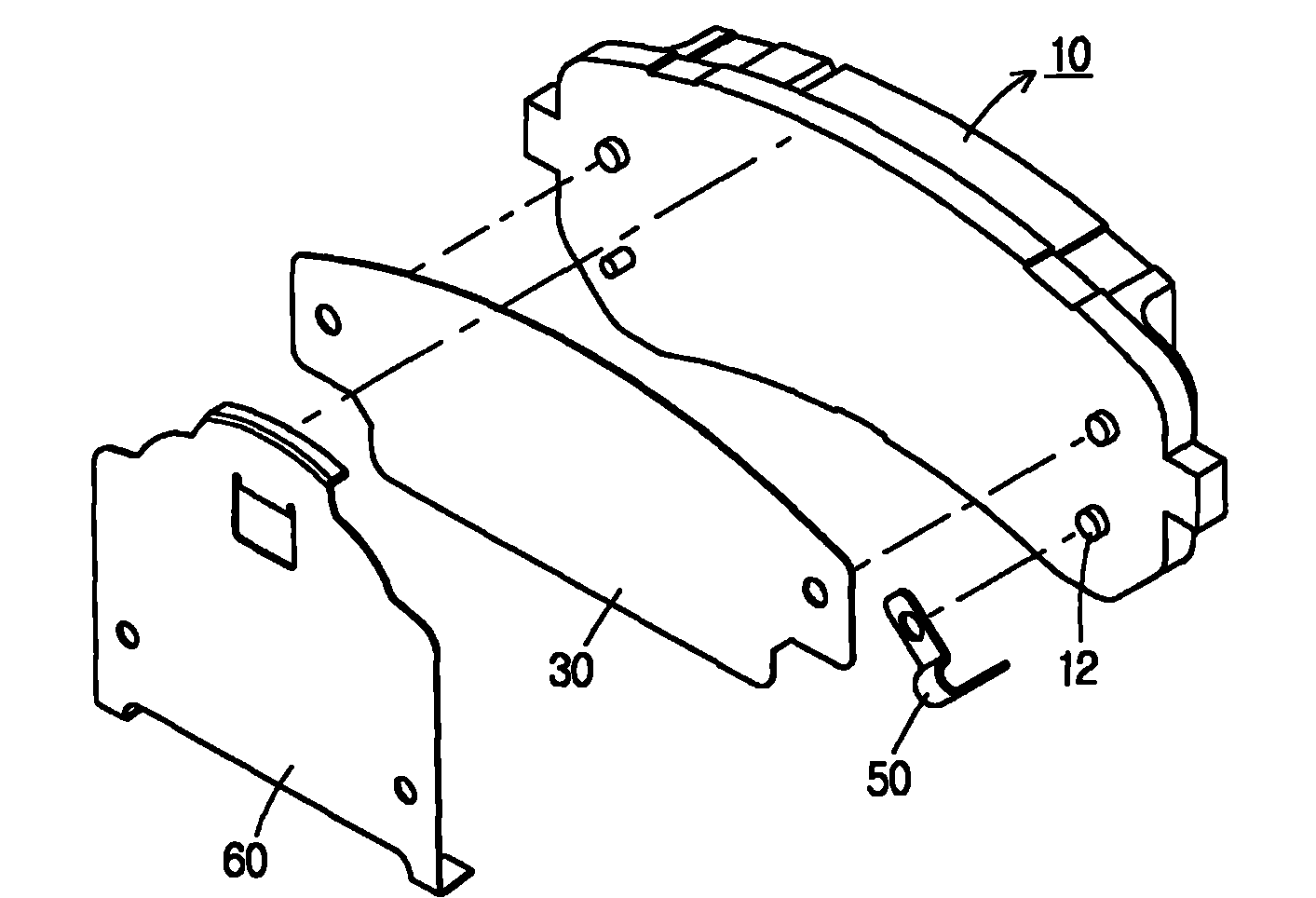

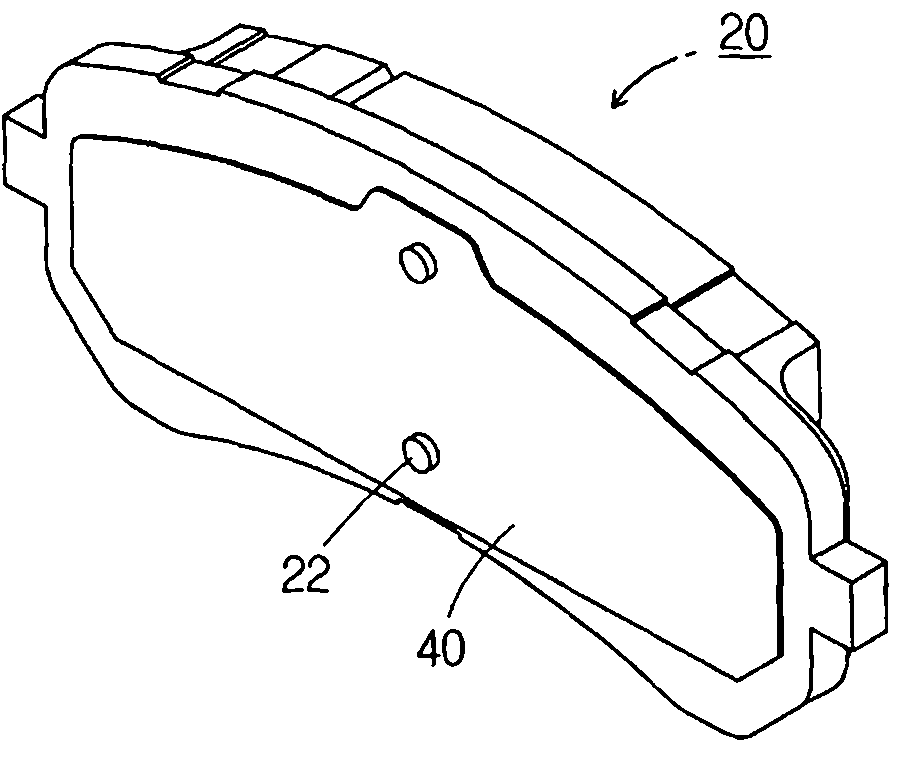

[0056] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Automobile brake pads with anti-noise plates are divided into inner / outer brake pads according to the position of the protrusion on the rear plate (back plate). Correspondingly, the anti-noise plates are also divided into inner / outer anti- Noise panels, therefore, in order to improve work efficiency, two anti-noise panel supply devices A and B are arranged side by side on the left and right, but in the following description, only one of the noise-proof panel supply devices will be described.

[0057] Figure 7 It is an oblique view of the present invention, Figure 8 It is a plane structure diagram of the present invention, Figure 9It is a side view of the present invention, and the noise-proof panel supply equipment A of the present invention includes: a loading machine 100, which is used to load the noise-proof panels 30, 40; The noise-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com