Directly buried maintenance-free sleeve compensator

A sleeve compensator, maintenance-free technology, applied in expansion compensation devices for pipelines, pipeline protection, pipeline protection through heat insulation, etc., can solve the problem of losing heat preservation, reducing the service life of sealing pairs, and not being able to adjust in time and other problems, to achieve the effect of simple built-in thermal insulation structure, long sealing performance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

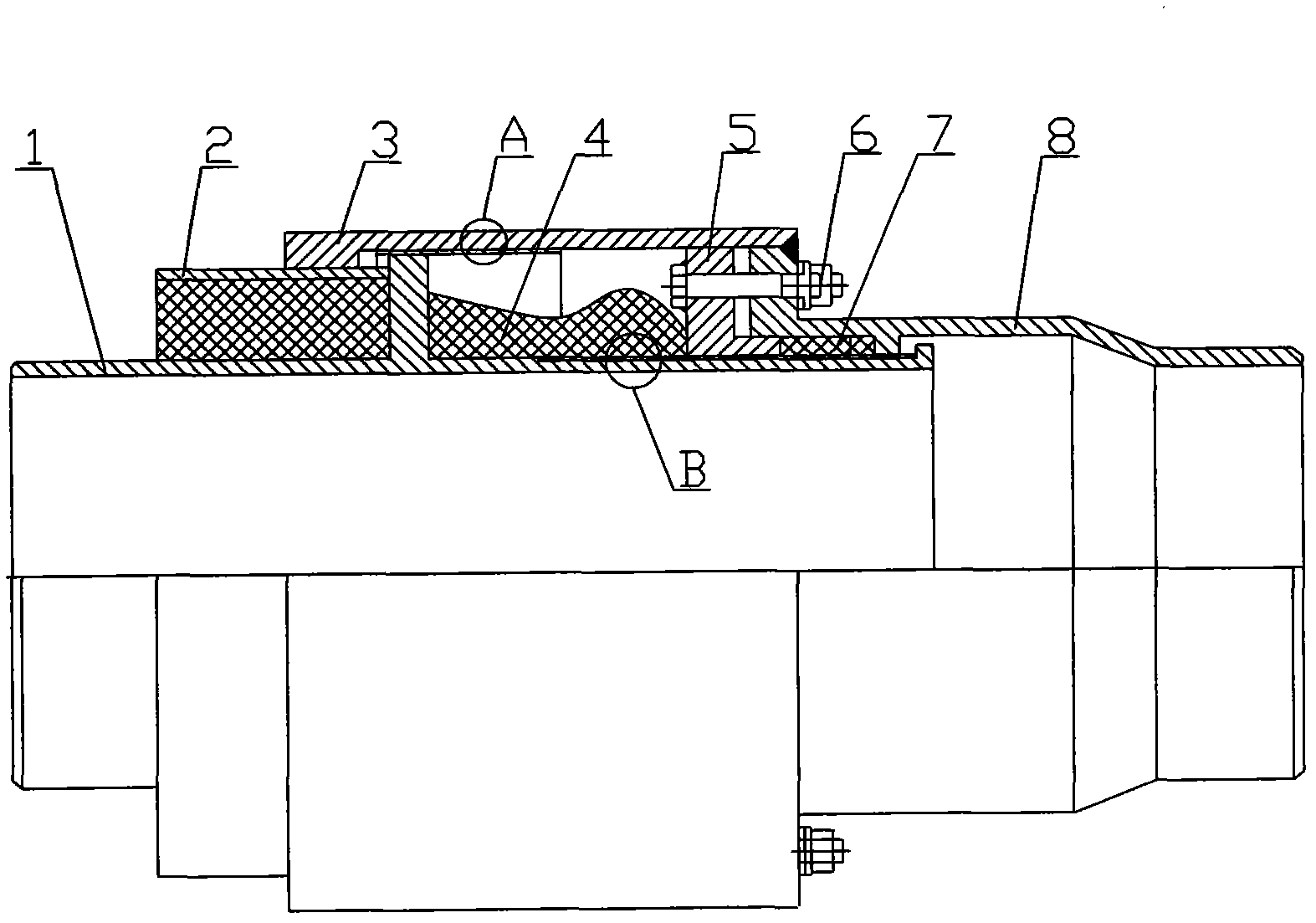

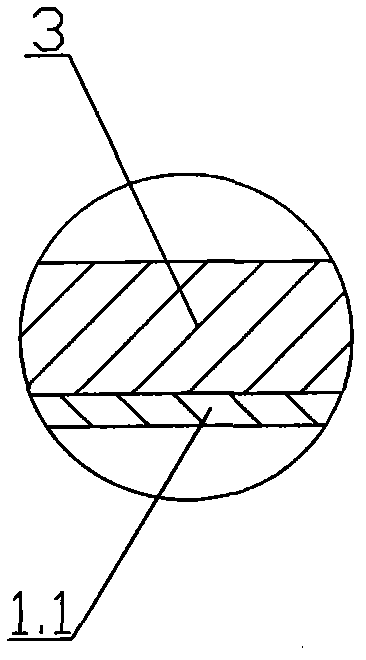

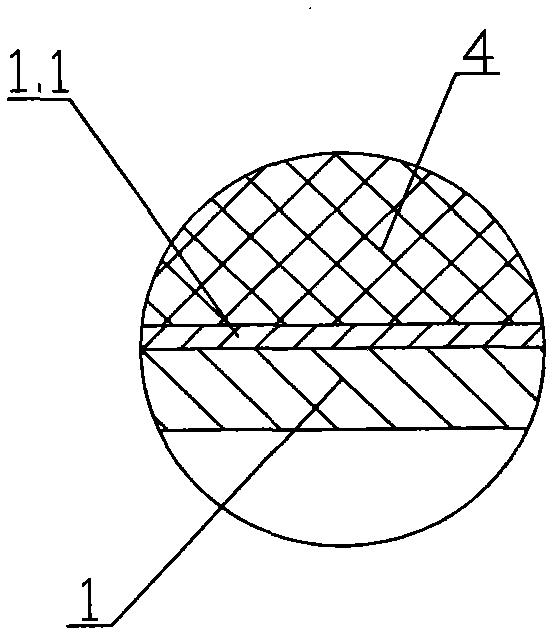

[0014] figure 1 The shown direct-buried maintenance-free sleeve compensator includes an inner tube 1 , a casing 2 , an outer shell 3 , an insulating material 4 , a gland 5 , a bolt assembly 6 , a packing 7 and an outer tube 8 . The inner tube 1 is one of the main components, mainly responsible for axial compensation and a certain amount of rotation compensation. The outer wall of the middle section of the inner tube 1 is provided with an annular boss, and the left end surface of the boss is coaxially fixedly connected to the sleeve 2 . The outer pipe 8 is a different-diameter pipe, and its large hole port is provided with an inner annular boss. The gland 5 is set on the inner pipe 1 to match the large hole of the outer pipe 8, and the annular boss is formed between the gland 5 and the outer pipe 8. Packing 7 is filled between the platforms, and the gland 5 is connected to the flange of the outer pipe 8 through the bolt assembly 6 to form a sealing adjustment structure. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com