Separator for preventing sabot from following

A separator and bulletproof support technology, which is applied in the test of ammunition, ammunition, weapon accessories, etc., can solve the problems of not considering the purity of projectile recovery, regardless of the trace and whereabouts of the bullet support, and complex structure, achieving simple structure and low cost. , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

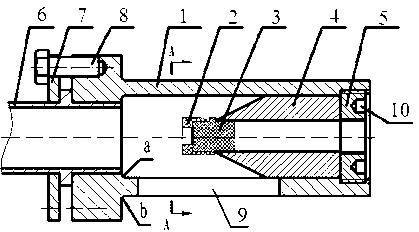

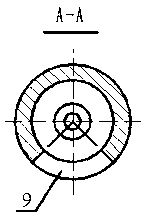

[0018] Referring to Fig. 1, Fig. 1 is a schematic diagram of the structure of the separation device followed by the bulletproof rest (the moment when the bullet rest and the projectile are separated) according to the present invention. Comprise projectile 3 and bullet holder 2, also comprise the separation chamber 1 of projectile 3 and bullet holder 2, this separation chamber 1 one end is connected with the outlet end of launching tube 6, and the other end is provided with top screw 5, and separation chamber 1 side is provided with There is a leak port 9; there is a separation block 4 in the cavity of the separation chamber 1, and the separation block 4 has a through central hole. One end of the separation block 4 is conical, and the other end is cylindrical, and the cylindrical end is in phase with the top screw 5. The contact is fixed on the port of the separation chamber 1 by the top screw 5; the conical installation position faces the launch tube 6 and is located above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com