Protective device for solid electrolytic capacitor body

A technology of solid-state electrolysis and protection devices, which is applied in the direction of solid electrolytic capacitors, capacitor shells/packages, and capacitor parts, etc., and can solve problems such as easy damage to capacitor components, excessive size, and excessive packaging pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

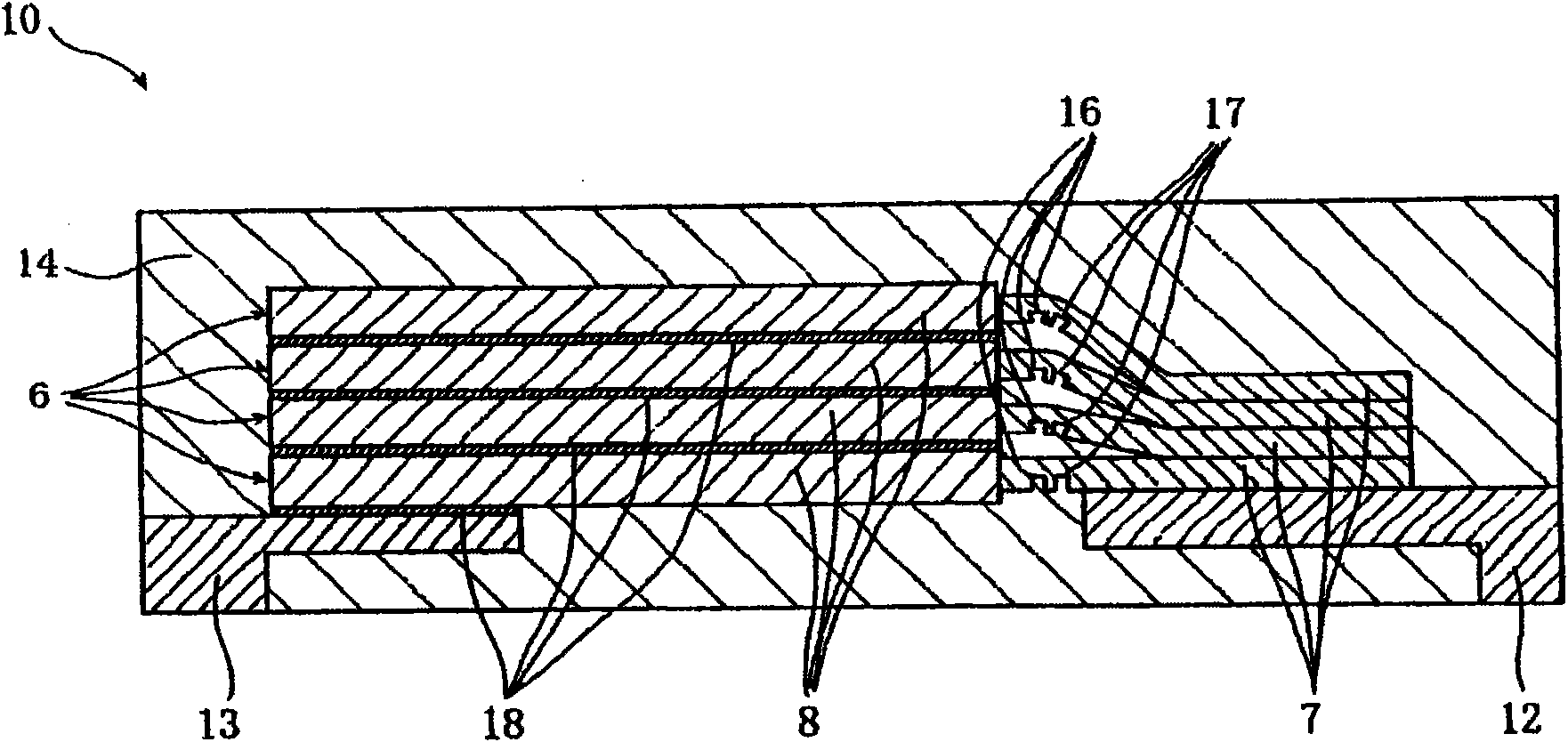

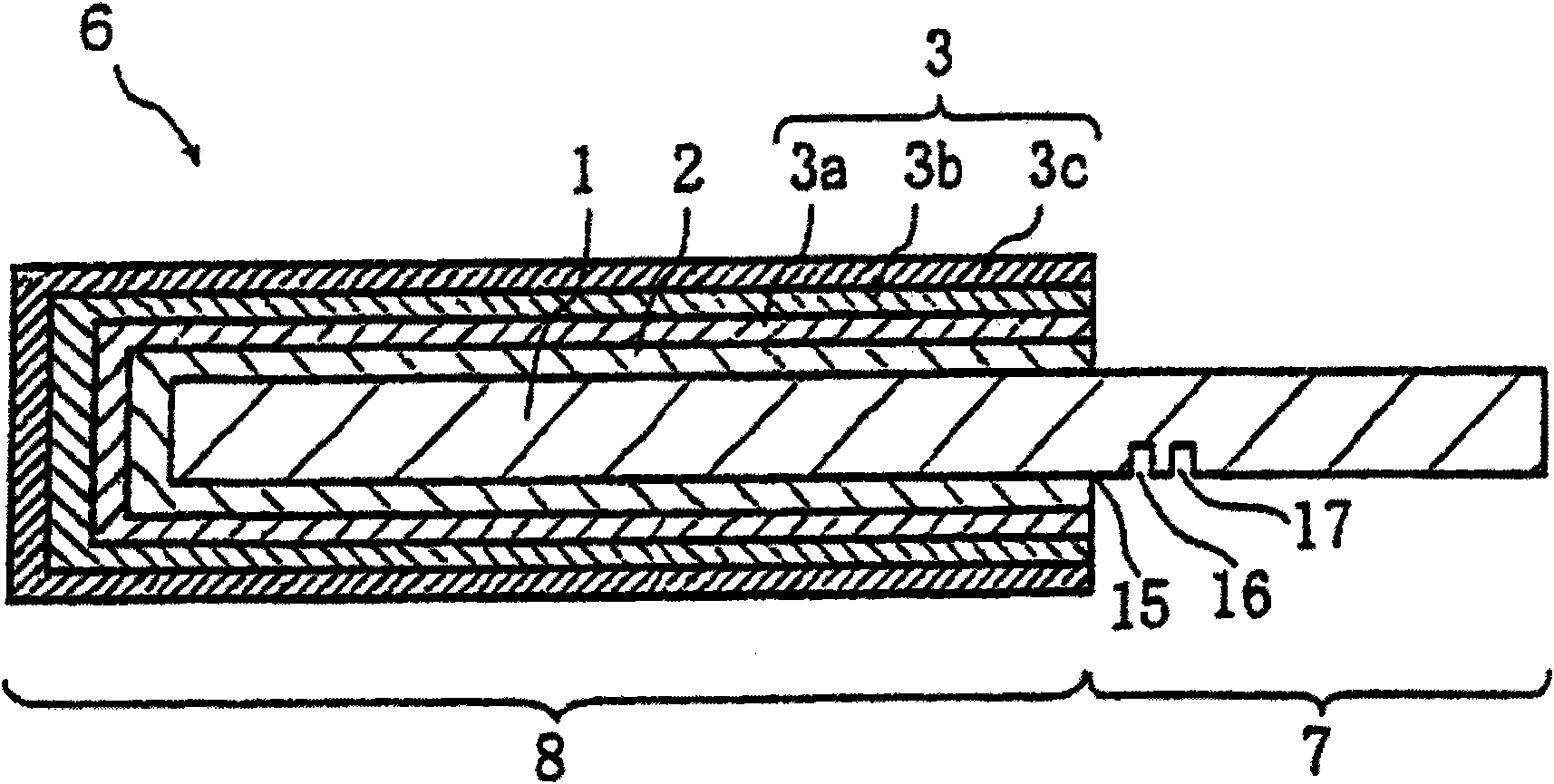

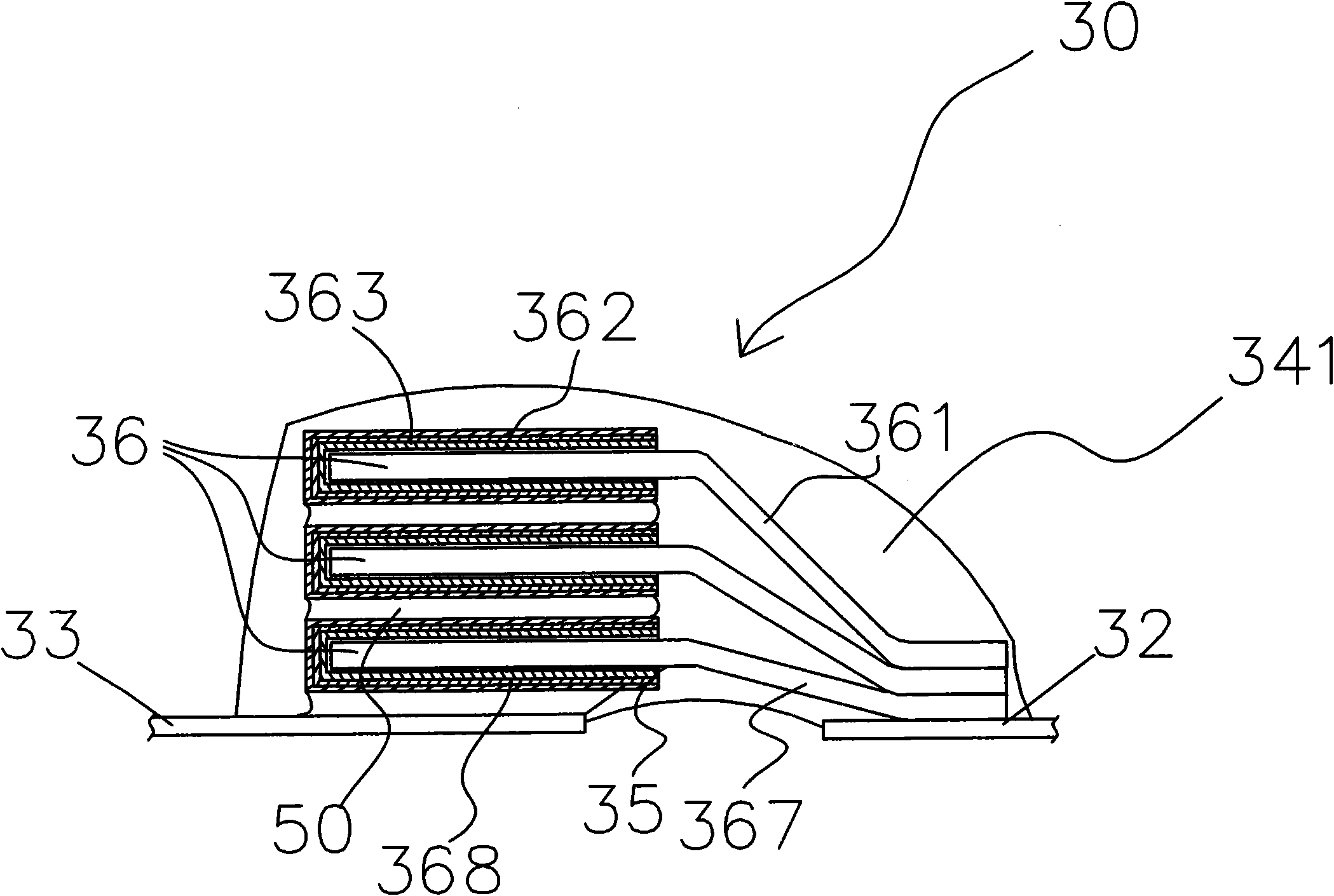

[0030] According to an embodiment of the present invention, a protection device for a solid electrolytic capacitor body is provided. Such as Figure 3-Figure 5 As shown, the present embodiment includes a solid electrolytic capacitor 30 . Among them, the solid electrolytic capacitor 30 includes a stacked multi-chip capacitor assembly 36, and the multi-chip capacitor assembly 36 is stacked on the anode terminal 32 and the cathode terminal 33; using packaging materials such as synthetic resin 34, the multi-chip The capacitor body composed of the capacitor assembly 36 , the anode terminal 32 and the cathode terminal 33 is packaged and fixed.

[0031] Among them, in the process of packaging and fixing, first, on the capacitor body composed of the multi-chip capacitor assembly 36, the anode terminal 32 and the cathode terminal 33, one or more layers of insulating glue and other packaging materials are applied. After drying and forming the airtight protective layer 341 (such as i...

Embodiment 2

[0035] Different from the above embodiment, in this embodiment, if Figure 6 and Figure 7 As shown, the solid electrolytic capacitor 30 includes a stacked multi-chip capacitor assembly 36, and the multi-chip capacitor assembly 36 is stacked on the anode terminal 32 and the cathode terminal 33; on the other side of the anode terminal 32 and the cathode terminal 33, parallel Another set of stacked multi-chip capacitor assemblies 36 is installed; the multi-chip capacitor assemblies 36, the anode terminal 32 and the cathode terminal 33 are packaged and fixed by using synthetic resin 34 through the encapsulation process to form another set of capacitor bodies.

[0036] Among them, in the process of encapsulating and fixing, at first, on the two groups of capacitor bodies formed by the multi-chip capacitor assembly 36, the anode terminal 32 and the cathode terminal 33, apply one or more layers of insulating glue, when the insulating glue dries After hard forming the airtight prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com