Threshing section for combine

A technology of combine harvester and threshing department, which is applied in threshing equipment, agricultural machinery and implements, applications, etc. It can solve the problems of blockage of threshing department and decline of threshing performance, so as to reduce grain loss, reduce overload and prevent flow delayed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

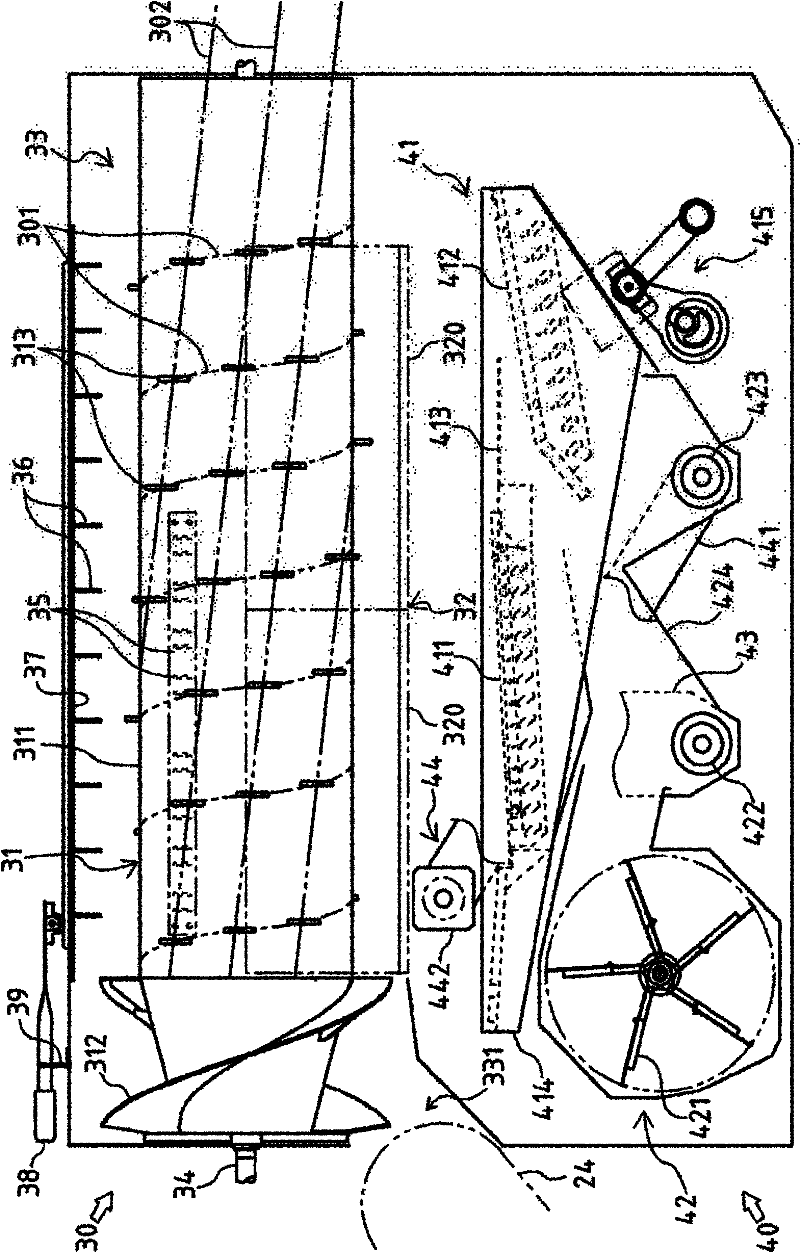

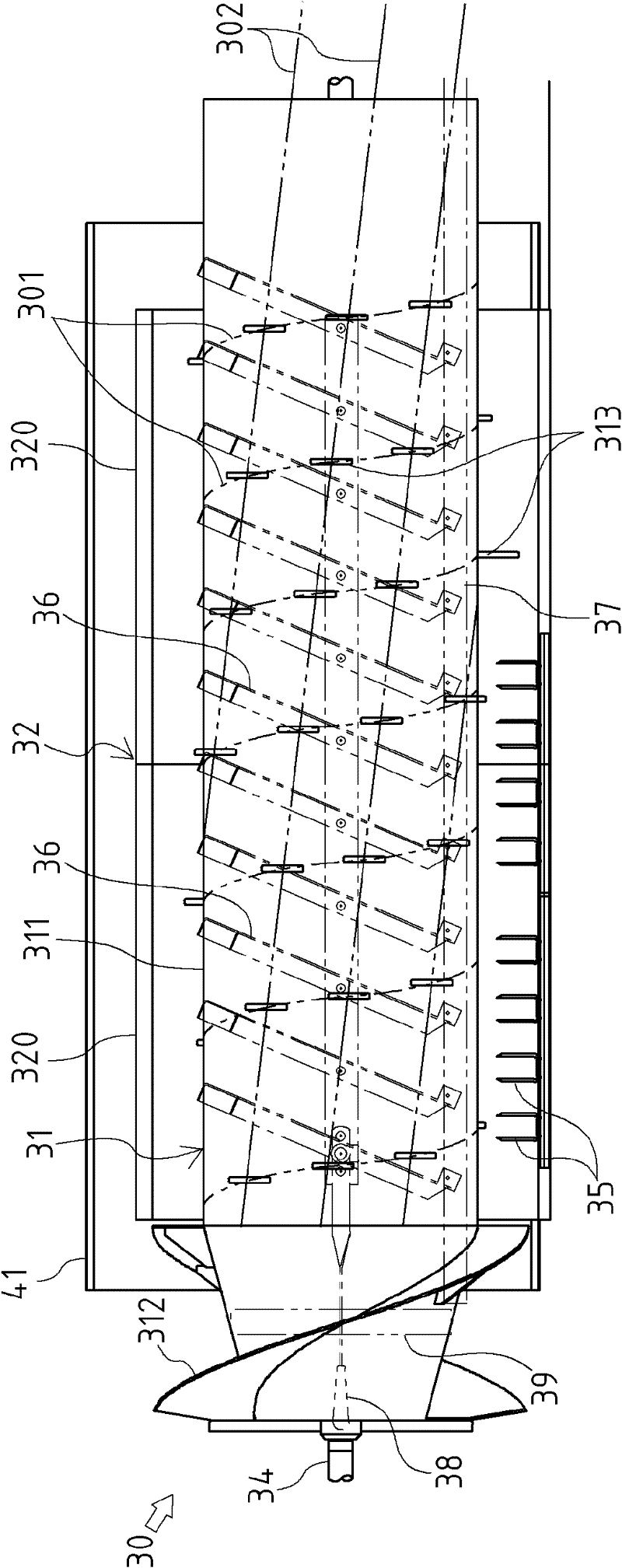

[0056] Next, embodiments of the invention will be described.

[0057] First, the whole structure of the combine 1 provided with the threshing part 30 which concerns on one Embodiment of this invention is demonstrated. In addition, the combine harvester 1 is a whole straw input type combine which throws in the whole straw, such as a soybean or wheat, in the threshing part 30, and performs threshing.

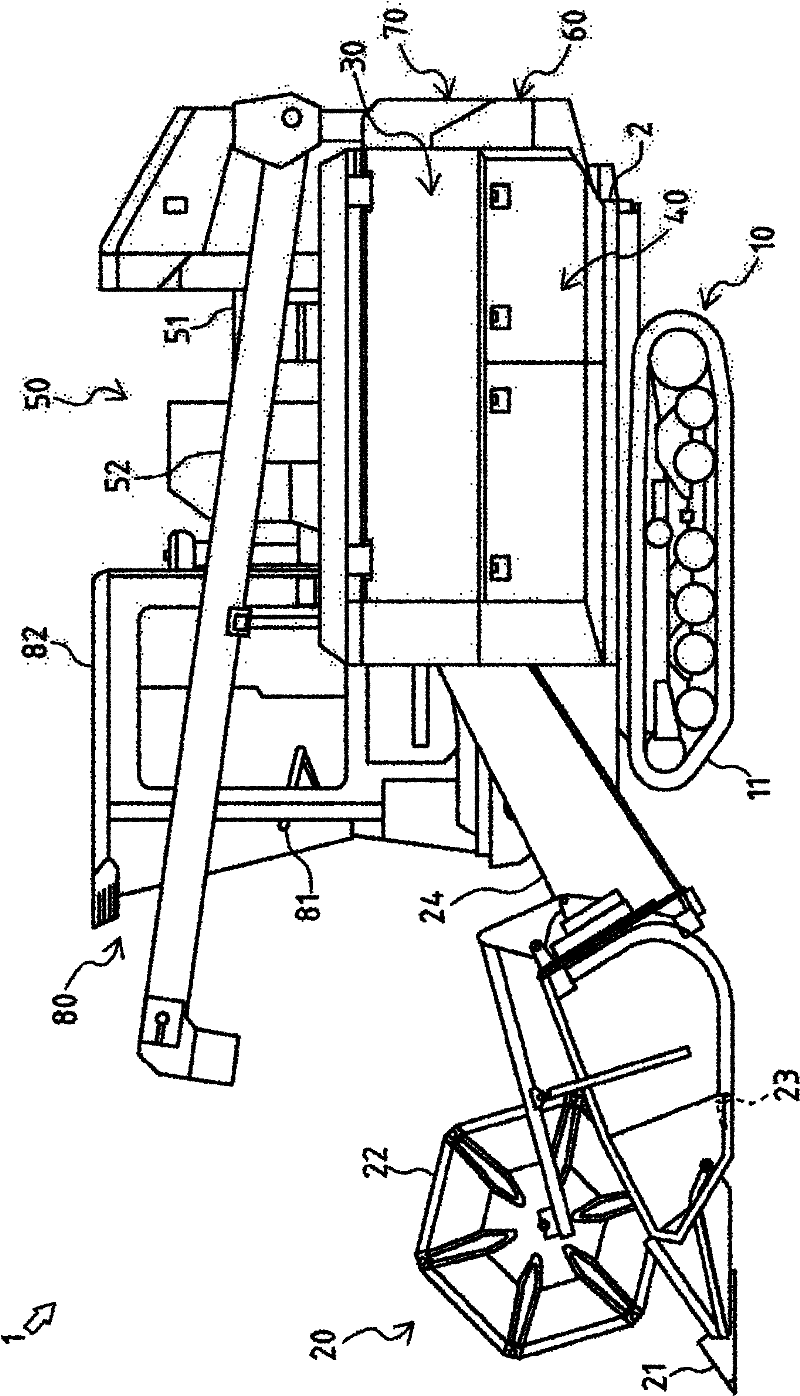

[0058] like figure 1 As shown, the combine harvester 1 is equipped with a running part 10, a harvesting part 20, a threshing part 30, a sorting part 40, a grain storage part 50, a grass discharge processing part 60, an engine part 70, and a driving part with respect to the fuselage frame 2. 80.

[0059] The running part 10 is provided at the lower part of the fuselage frame 2 . The traveling unit 10 is configured to include a crawler-type traveling device 11 including a pair of left and right crawlers, and the crawler-type traveling device 11 can move the fuselage in the forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com