Detection of distillation column flooding

An overflow and fluid path technology, which is used in the field of distillation process and the detection of overflow conditions in the distillation column, can solve the problems of destroying the runaway conditions of the distillation process, system shutdown, product loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

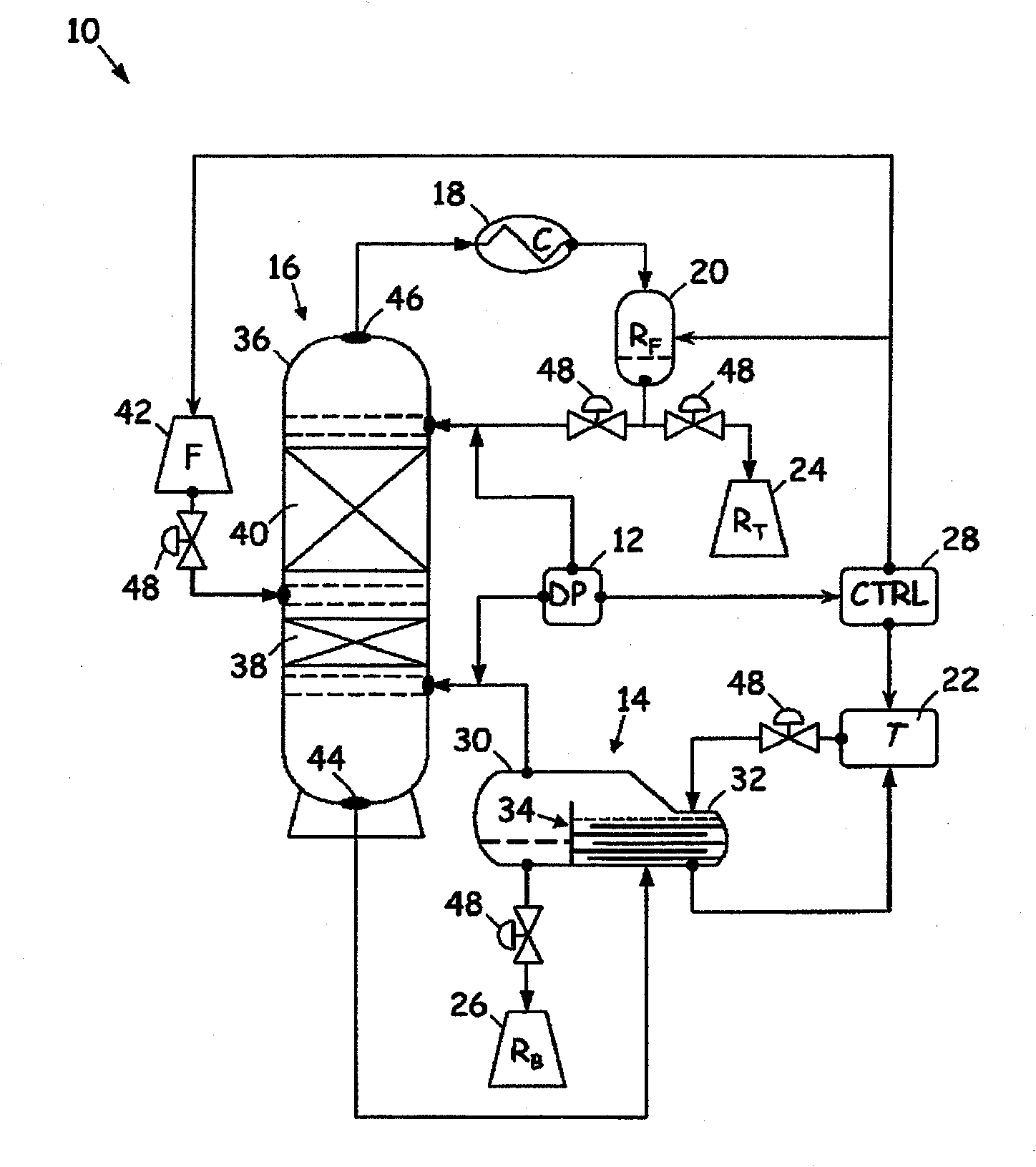

[0016] figure 1 is a cross-sectional view of a distillation system 10 with a differential pressure (DP) transmitter 12 for detecting column flooding. Distillation system 10 includes DP transmitter 12 , reboiler 14 , distillation column 16 , liquefier 18 , reflux drum 20 , heat source 22 , receiver 24 for overhead product (liquefied), and reservoir 26 for bottoms product. Transmitter 12 generates a flood indicator based on the differential pressure signal in distillation column 16 , and controller 28 controls system 10 based on control inputs including the flood indicator from transmitter 12 .

[0017] The DP transmitter 12 is a field device or other measuring device configured to sense the pressure differential across the vertical height (i.e., along the direction of distillation gas flow) of the target column distillation column 16 and configured to send a message to an operator or process controller Indicates the output of the pressure. In some embodiments, for example, tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com