Power device

A technology of power plant and speed change device, which is applied in power plant, pneumatic power plant, electromechanical transmission device, etc., can solve the problems of low degree of freedom, large-scale power plant, increased manufacturing cost, and increased manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

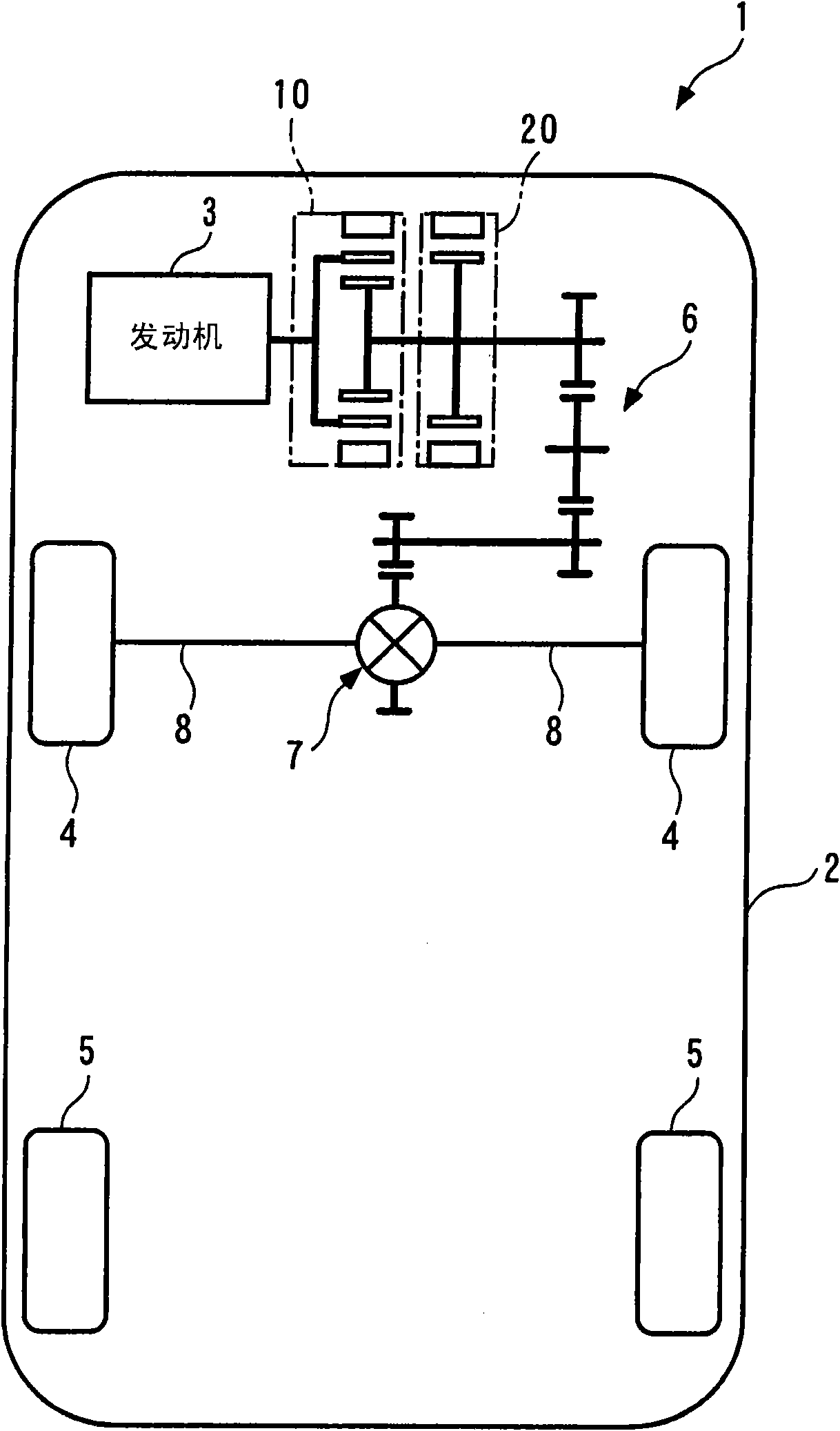

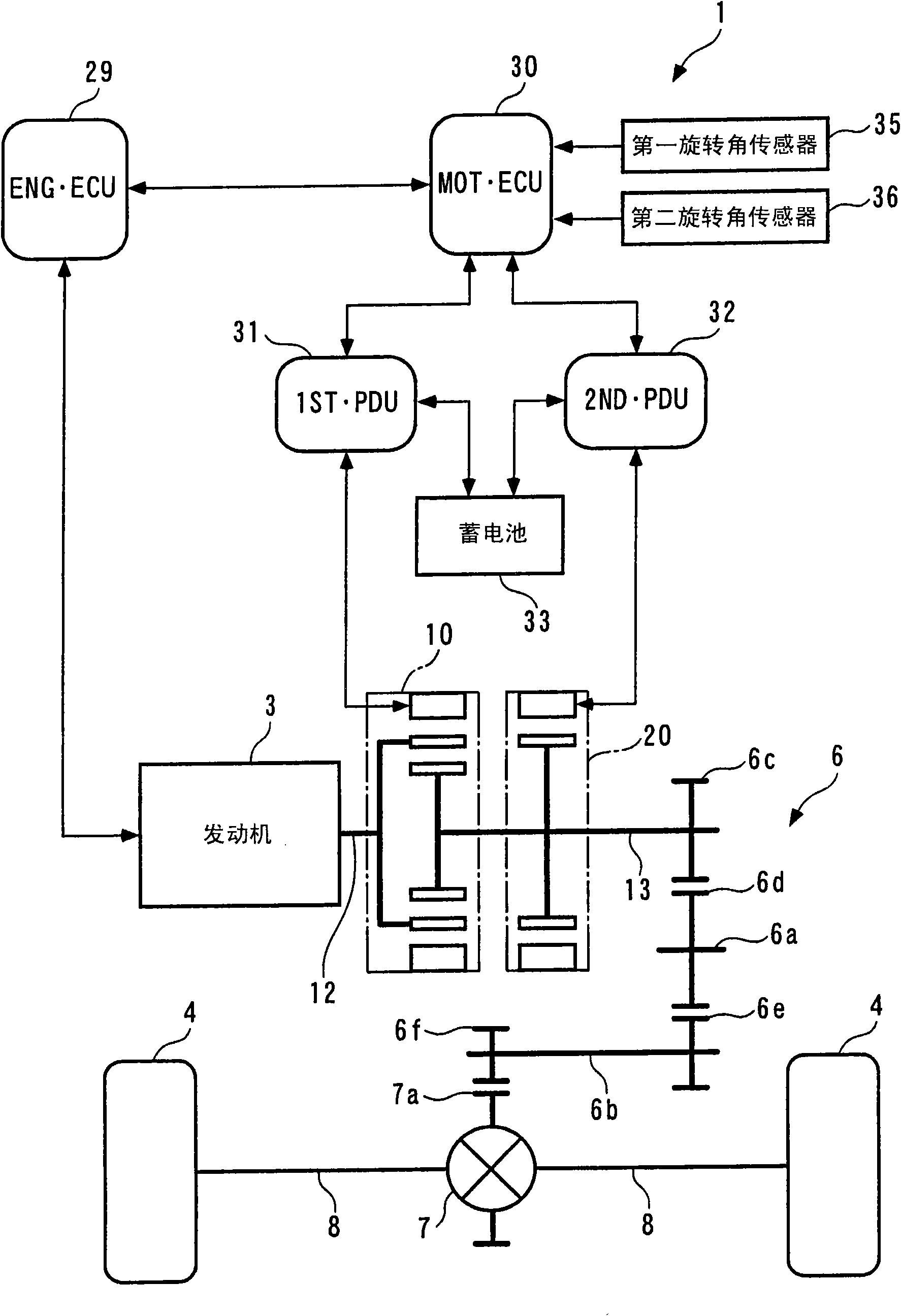

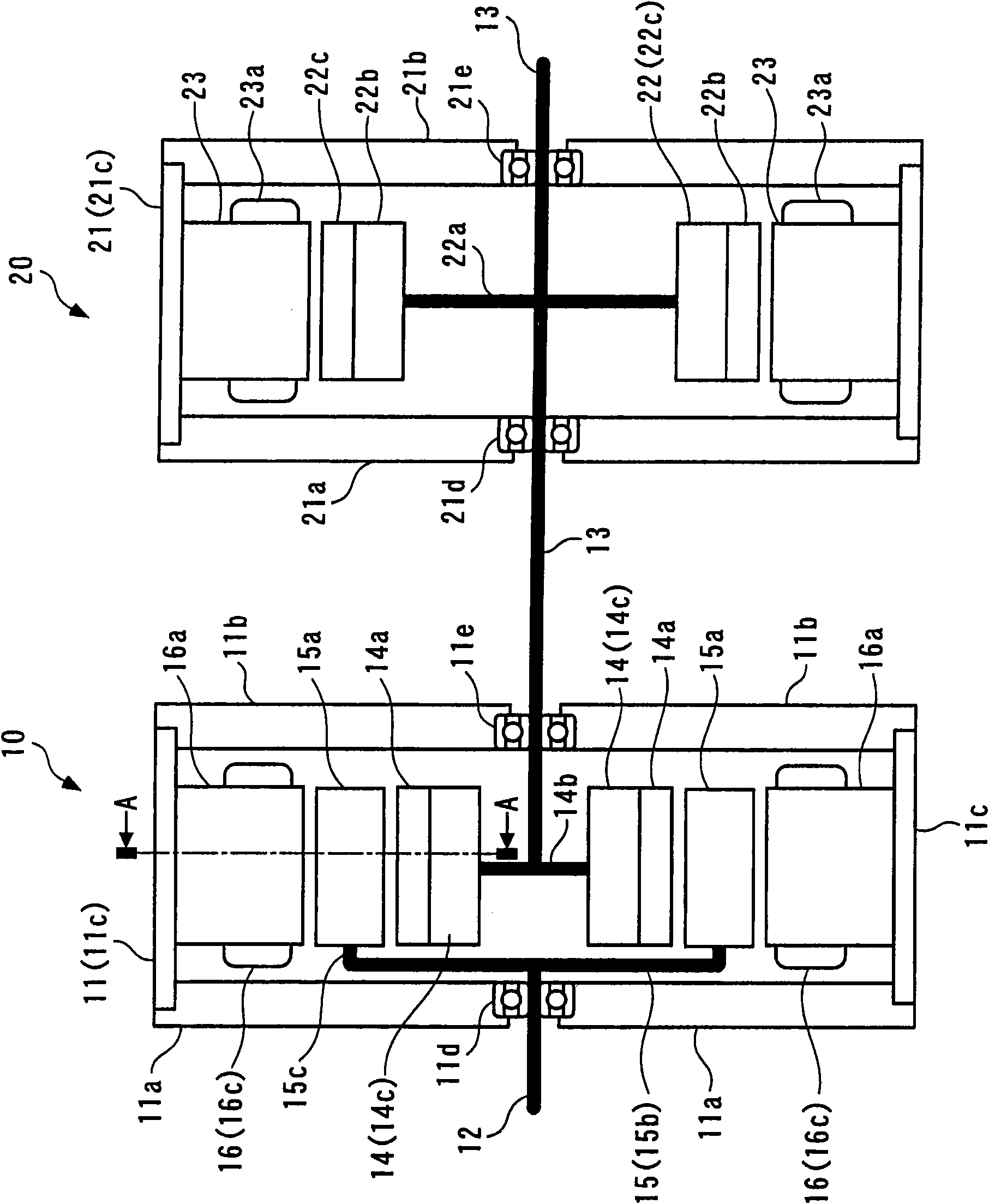

[0162] Hereinafter, a power plant according to a first embodiment of the present invention will be described with reference to the drawings. Also, in the following description, the Figure 1 ~ Figure 3 The left and right sides of are referred to as "Left" and "Right", respectively. Such as figure 1 and figure 2 As shown, the power plant 1 of this embodiment is a device that drives the left and right front wheels 4, 4 of a hybrid vehicle (hereinafter referred to as "vehicle") 2, and includes an engine 3, a first rotating machine 10, and a second rotating machine 20 as a power source.

[0163] In this vehicle 2, the engine 3 is connected to the first rotating machine 10, and the first rotating machine 10 and the second rotating machine 20 are connected to the left and right front shafts via the gear mechanism 6, the differential gear mechanism 7, and the left and right drive shafts 8, 8. Wheel 4, 4 links. Thereby, the power of the engine 3 or the power of the first rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com