Thermoplastic elastomers exhibiting superior abrasion resistance properties

A technology of thermoplastic elastomers and elastomers, applied in the field of thermoplastic polyester elastomers, can solve the problems of TPE lack of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation of the compounds according to the invention is uncomplicated. The compounds of the present invention can be prepared in batch or continuous operation.

[0037] Compounding in a continuous process typically occurs in an extruder that is brought to a temperature high enough to melt the polymer matrix and add solid ingredient additives either at the head of the extruder or downstream of the extruder. The temperature is above the melting temperature of the thermoplastic elastomer to allow good dispersion of all ingredients into the blend, typically above 210°C. The speed of the extruder can be in the range of about 50-500 revolutions per minute (rpm), preferably about 400 rpm. Typically, the output of the extruder is pelletized for subsequent extrusion or molding into polymeric articles.

[0038] The mixing in the batch process is usually carried out in a Banbury mixer which is also brought to a temperature high enough to melt the polymer matrix to allow t...

Embodiment

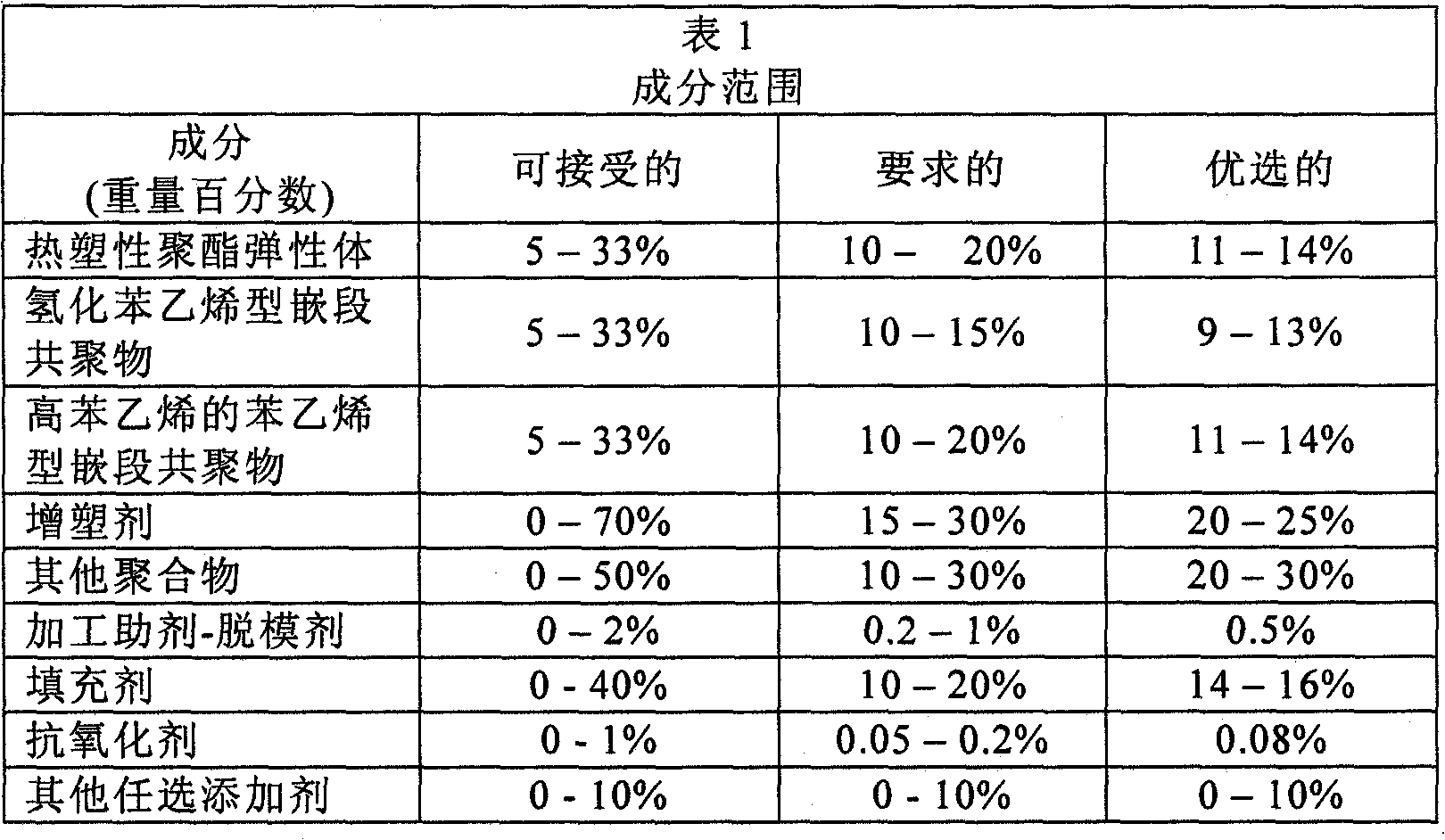

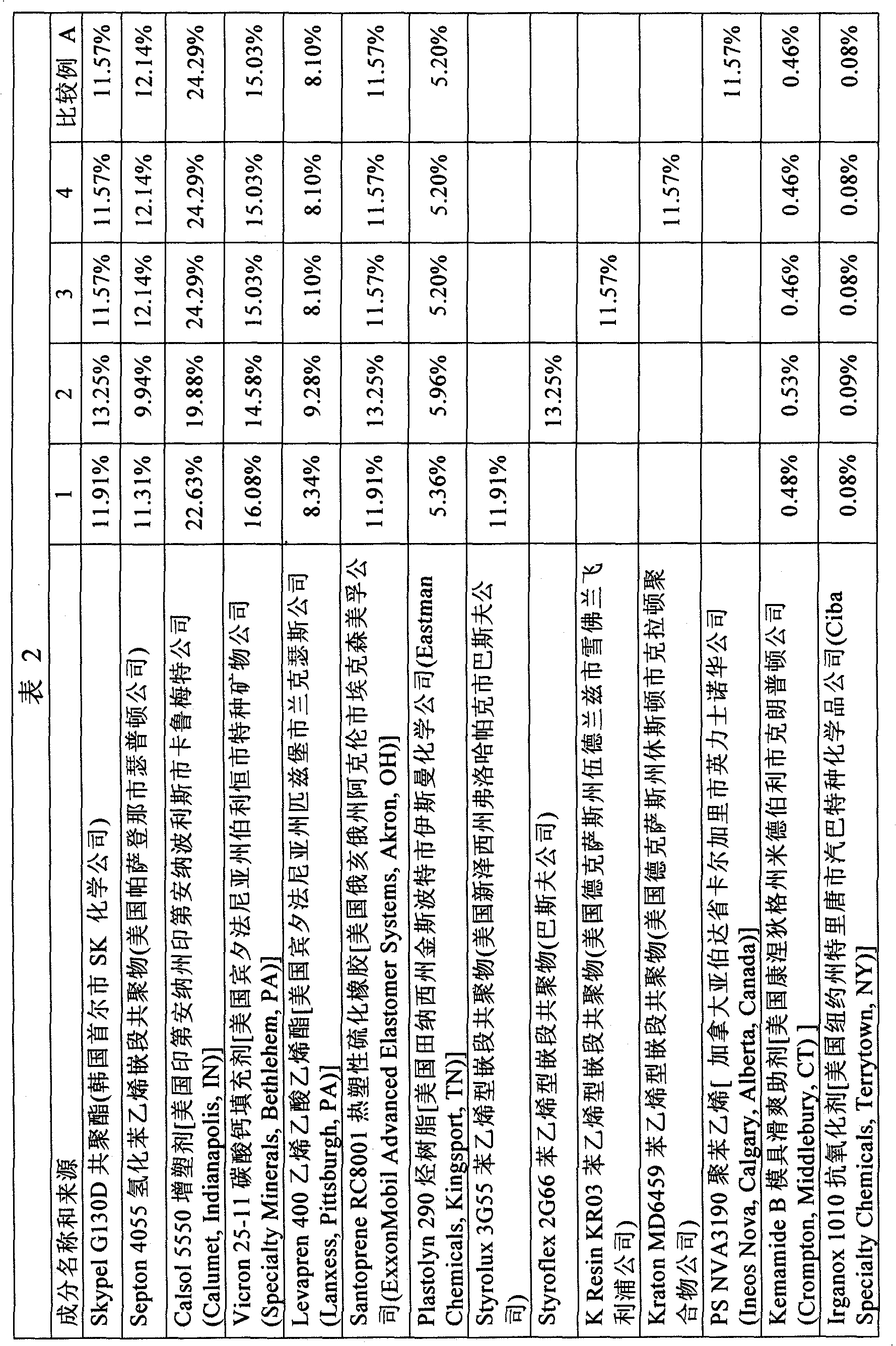

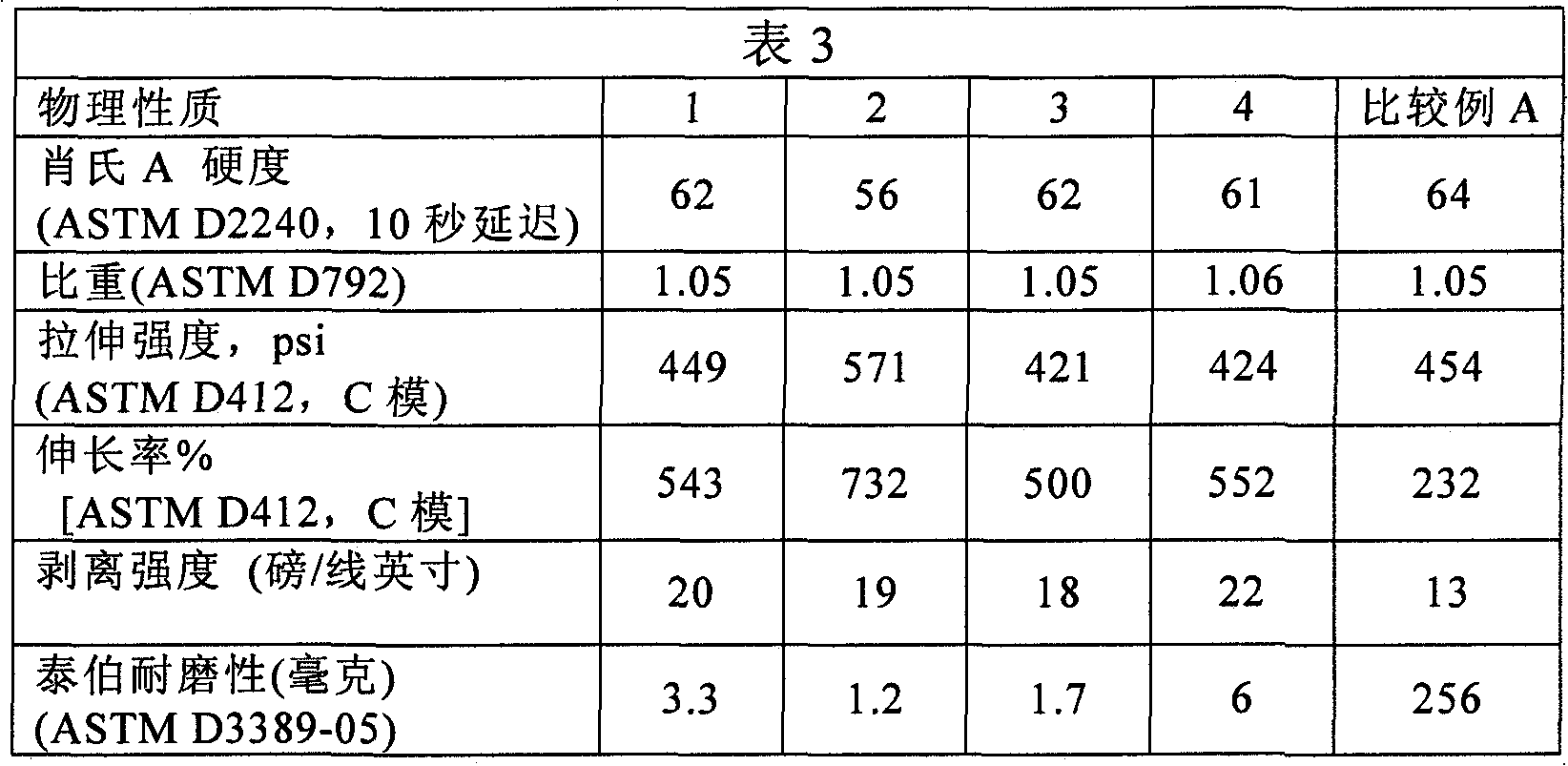

[0045] Table 2 shows four examples of the present invention and compared with the control case (comparative example A).

[0046] All formulations of Examples 1-4 and Comparative Example A contained similar weight percent ingredients, except that Comparative Example A used polystyrene, which is commonly used in thermoplastic elastomers, and Examples 1-4 used high-styrene styrene Ethylene block copolymers.

[0047]

[0048] Examples 1-4 and A were all prepared using a twin screw extruder with all zones set at 216°C (420°F) at 400 rpm. All ingredients were added before Zone 1. The melt-mixed compound is pelletized for further processing.

[0049] All pellets of Examples 1-4 and A were molded into tensile test bars using an injection molding machine from Demag, at a temperature of 230° C. and under high pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com