Combined greening body

A green body, combined technology, applied in container cultivation, horticulture, botanical equipment and methods, etc., can solve the problems of inability to meet plant growth requirements, inability to produce and manufacture, and high cost, and achieves benefits for plant growth and watering. Management, cost minimization, rapid nutrient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

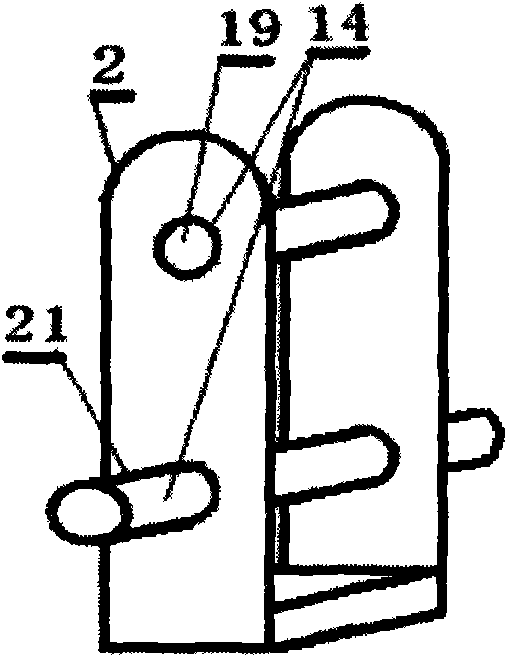

[0061] Example 1: see figure 1 , Image 6 , Figure 8 , the combined greening body is characterized in that: the greening body is formed by splicing a substrate 3 with two planting surfaces, the substrate 3 is formed by direct splicing of a transverse member 1 and a support 2, and the direct splicing support 2 is a A part symmetrical to the central axis in the vertical direction, the transverse member 1 has a planting bearing part for accommodating medium or flower pots, the upper surface of the transverse member 1 is the planting surface 4, and the transverse member 1 has water supply and drainage holes 11; the support 2 and the transverse member 1 They are manufactured separately. Direct splicing means that there are matching positioning splicing structures on the cross member 1 and support 2. The positioning splicing structure is a combination of convex grooves and grooves and convex grooves and holes. A complete base 3 is only made of The horizontal member 1 and the supp...

Embodiment 2

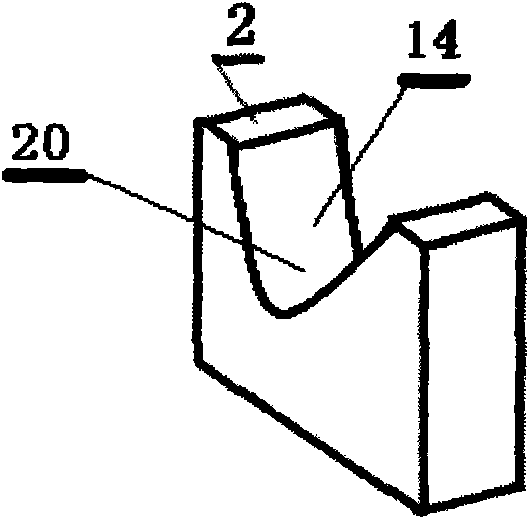

[0066] Example 2: see figure 2 , Image 6 , Figure 10 , the combined greening body is characterized in that: the greening body is composed of a splicing base 3 with a planting surface, the base 3 is formed by direct splicing of a transverse member 1 and a support 2, and the direct splicing support 2 is a A part symmetrical to the axis of the central axis, the transverse member 1 has a planting bearing part for containing medium or flower pots, the upper surface of the transverse member 1 is the planting surface 4, and the transverse member 1 has water supply and drainage holes 11; the support 2 and the transverse member 1 are respectively Manufacturing, direct splicing means that there are matching positioning splicing structures on the cross member 1 and the support 2, the positioning splicing structure is a combination of convex grooves and grooves, and a complete base 3 is only passed by the cross member 1 and the support 2 The positioning and splicing structures on the...

Embodiment 3

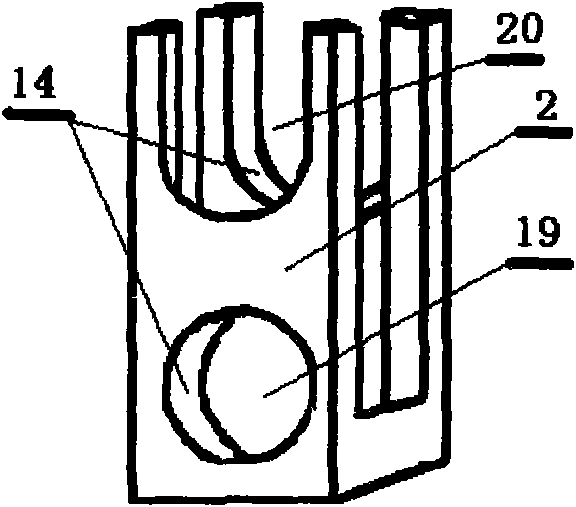

[0071] Embodiment 3: see image 3 , Figure 5 , Figure 7 , Figure 9 , the combined greening body is characterized in that: the greening body is formed by splicing a substrate 3 with two planting surfaces, the substrate 3 is formed by direct splicing of a transverse member 1 and a support 2, and the direct splicing support 2 is a A part symmetrical to the central axis in the vertical direction. The cross member 1 has a planting bearing part for accommodating medium or flower pots. The upper surface of the cross member 1 is the planting surface 4. There are water supply and drainage holes 11 on the cross member 1. The support 2 and the cross member 1 It is manufactured separately. Direct splicing means that there are matching positioning splicing structures on the cross member 1 and the support 2. The positioning splicing structure is a combination of protrusions and holes. A complete base 3 is only composed of the cross member 1 and the support 2. By matching and splicing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com