Adhesive tape cutting device

A tape and cutter technology, applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of use impact, insufficient cutting accuracy, large volume, etc., to achieve easy movement and placement, low manufacturing cost, overall Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

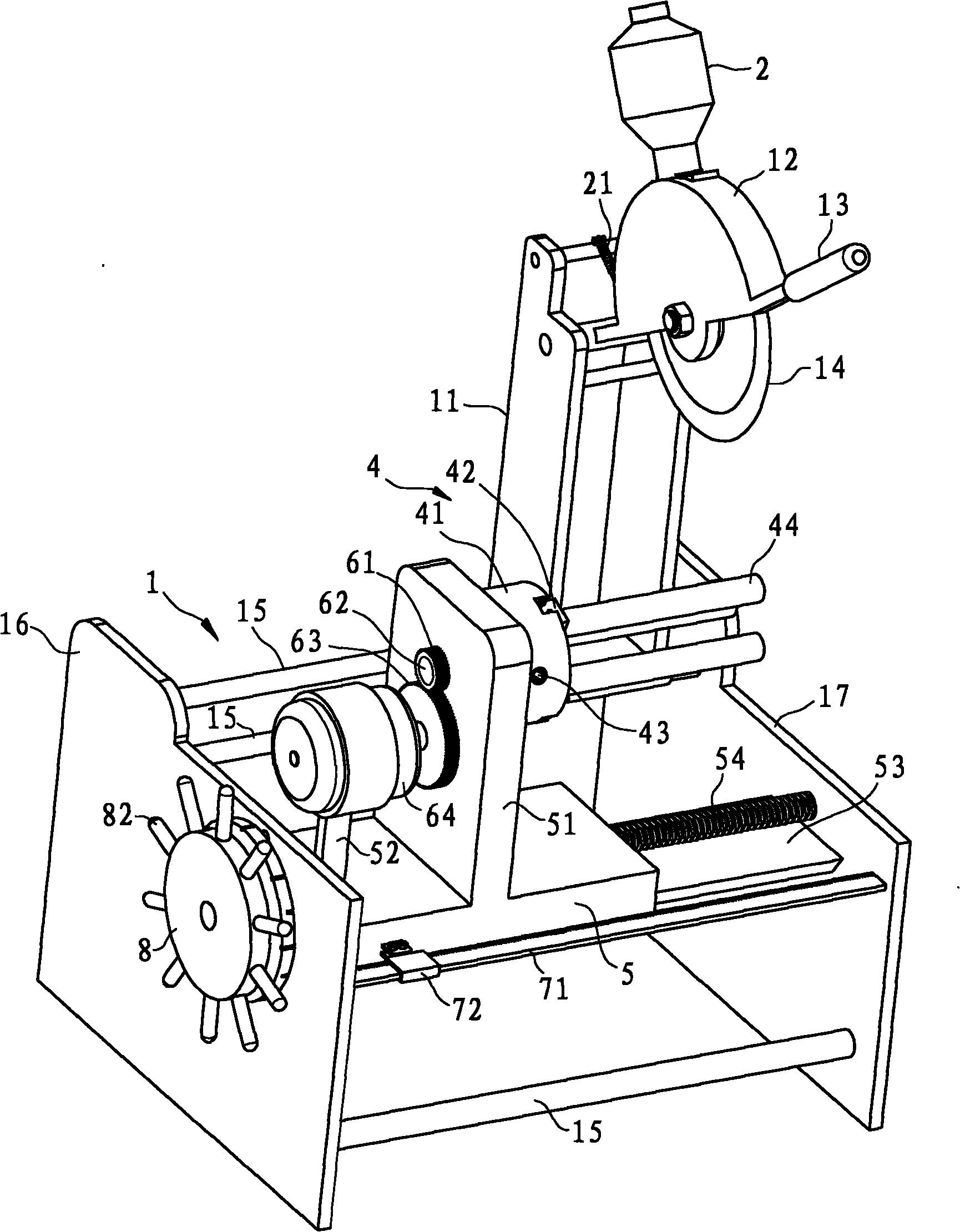

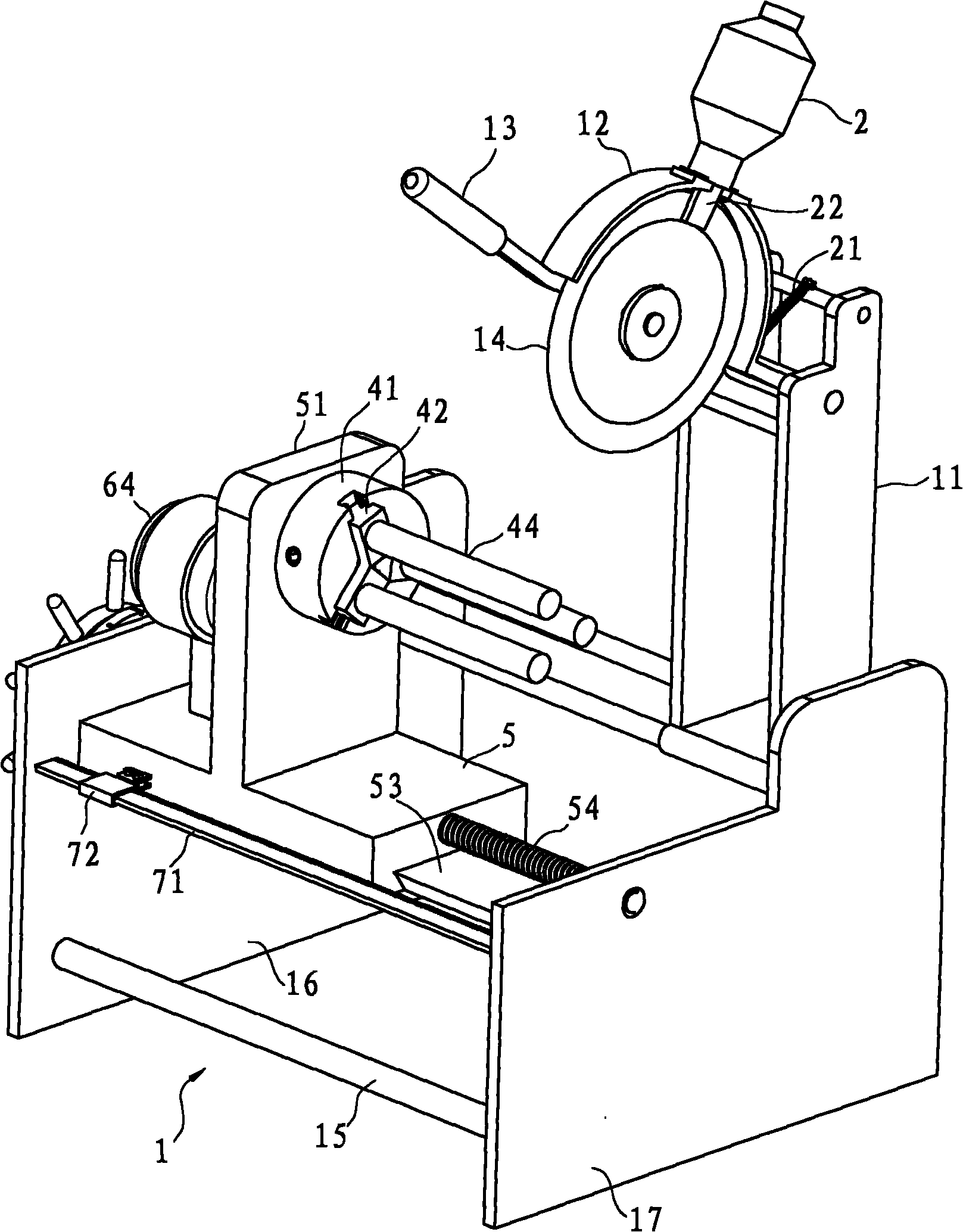

[0035] The tape cutting device in this embodiment includes a base frame 1, a slider 5, a motor 64, a clamping mechanism, a knife rest 11, a knife seat 12, a cutter 14 and an adjustment mechanism.

[0036] The base frame 1 comprises a left vertical board 16, a right vertical board 17 and a plurality of connecting rods 15 for connecting the left vertical board 16 and the right vertical board 17, the parallel connecting rods 15 are provided with guide rails 53, and the slider 5 can slide horizontally. It is arranged on the base frame 1 and has a vertical portion 51 , and the bottom of the slider 5 has a guide groove cooperating with the guide rail 53 . The motor 64 is arranged on one side of the vertical portion 51 of the slider through the fixing ring 52 .

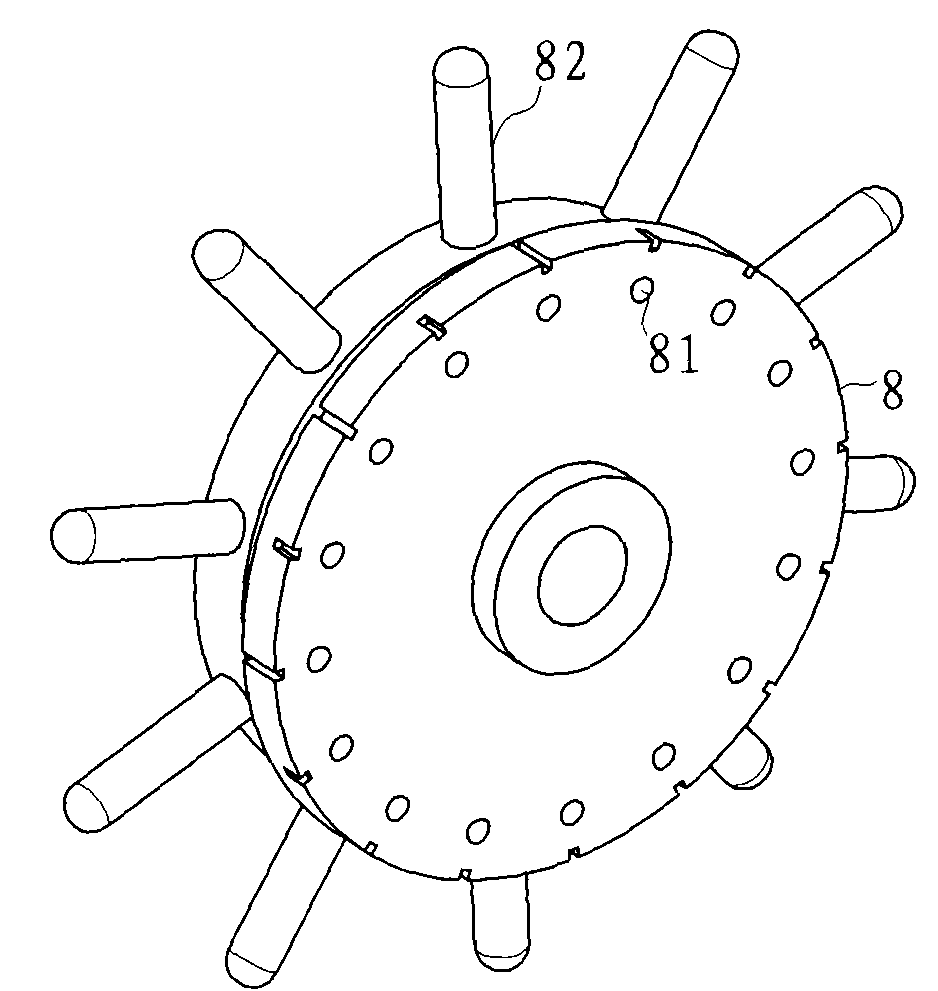

[0037] to combine Figure 5 As shown, the clamping mechanism is used to clamp the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com