Method and device for measuring balance coefficient of elevator

A technology of balance coefficient and measuring device, which is applied in the direction of measuring device, static/dynamic balance test, machine/structural component test, etc., to achieve the effect of simple structure, reduced labor intensity and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

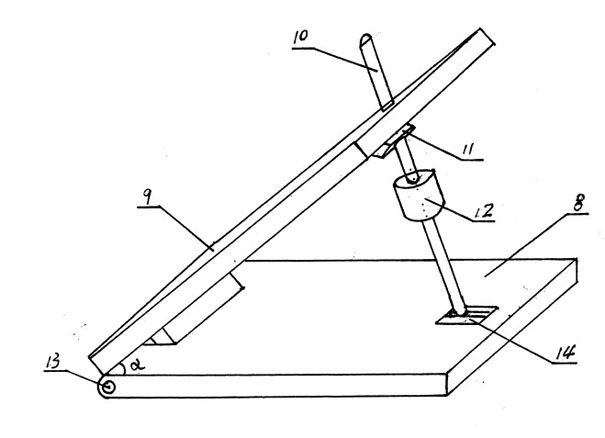

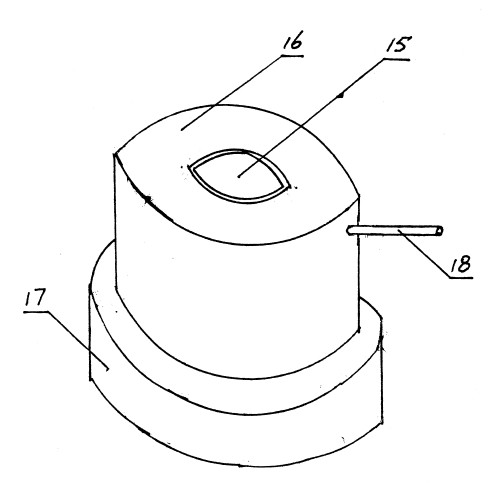

[0063] Such as Figure 4 As shown, the measuring device of the elevator balance coefficient is arranged on the counterweight side of the elevator, and the elevator car and the elevator counterweight are hung on both sides of the elevator traction sheave 19 through the traction wire rope 1 . The wire rope clamp 20 is fixedly mounted on the traction wire rope 1, the two adjustable brackets 22 are respectively fixed on the channel steel 21 of the traction frame on the counterweight side, and the two load cells 23 are respectively fixed on two adjustable brackets. On the bracket 22 , adjusting the adjustable bracket 22 can ensure that the force-bearing surface of the load cell 23 is always perpendicular to the traction wire rope 1 . The ammeter is connected to the two load cells 23 for reading the values measured by the load cells.

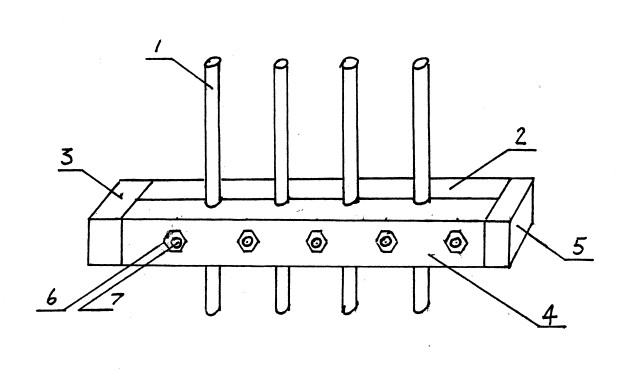

[0064] Such as figure 1 As shown, the wire rope clamp is the force transmission part in the present invention. When it is used to measure the wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com